Power Node/30

1650, Issue 1, March 2011

10

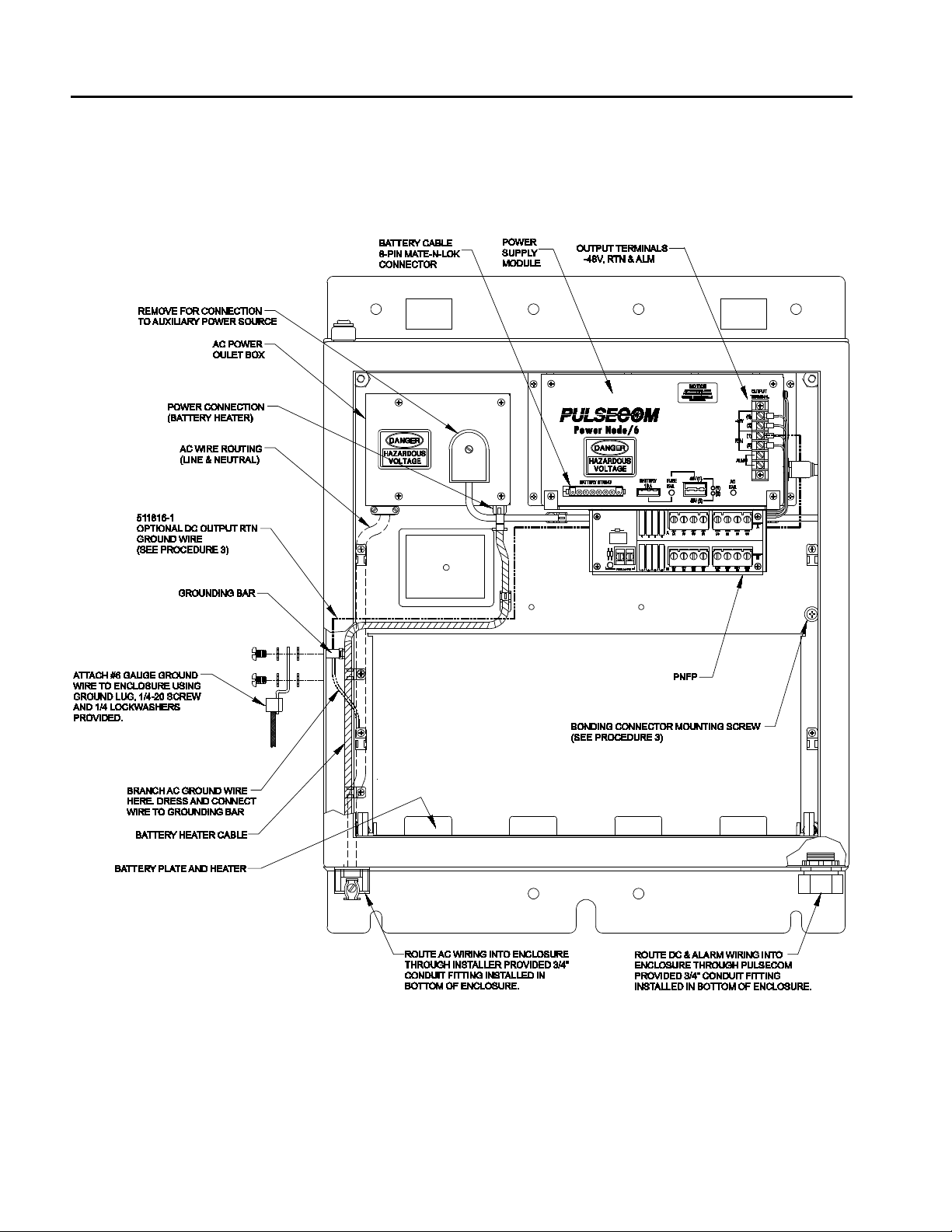

Make wiring and battery connections as described in Procedure 3.

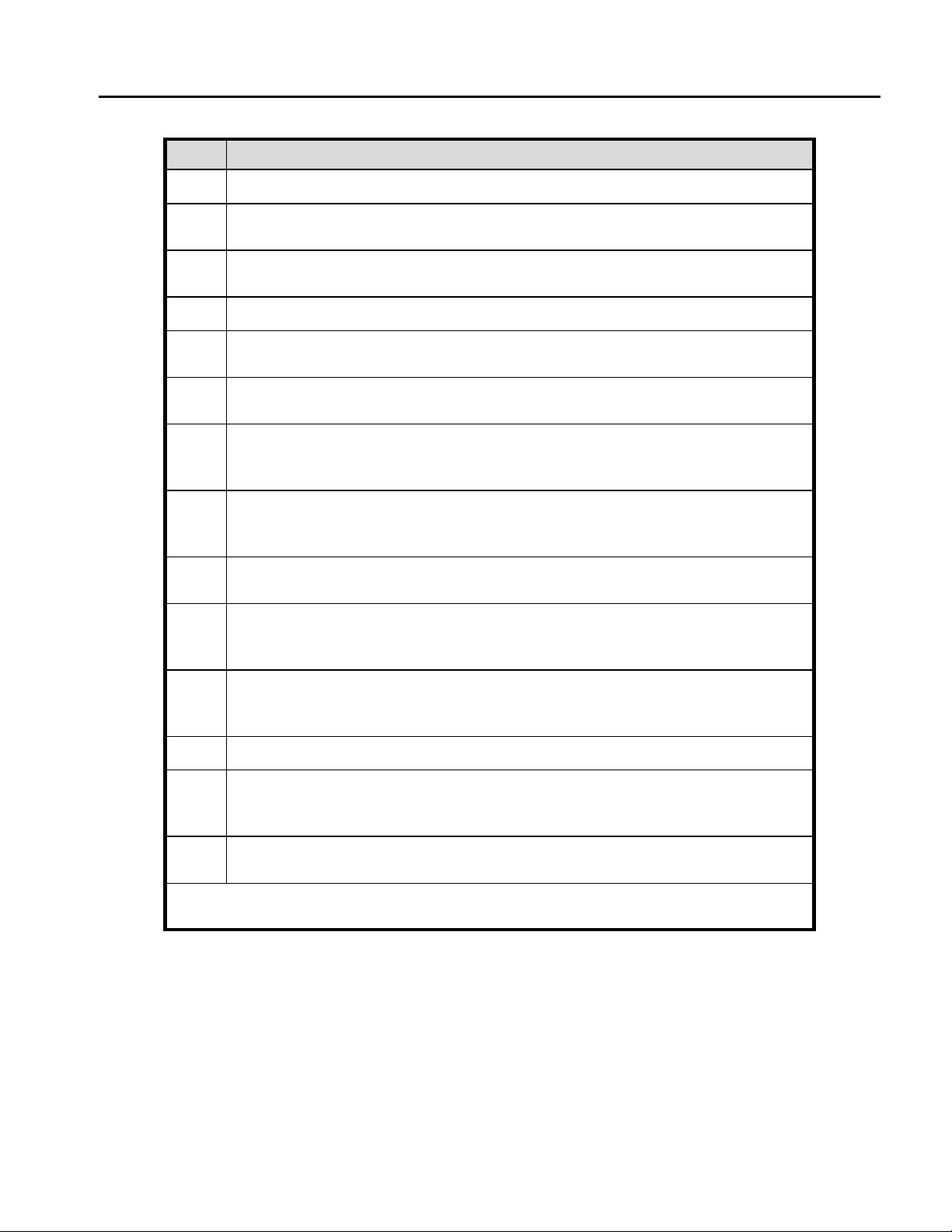

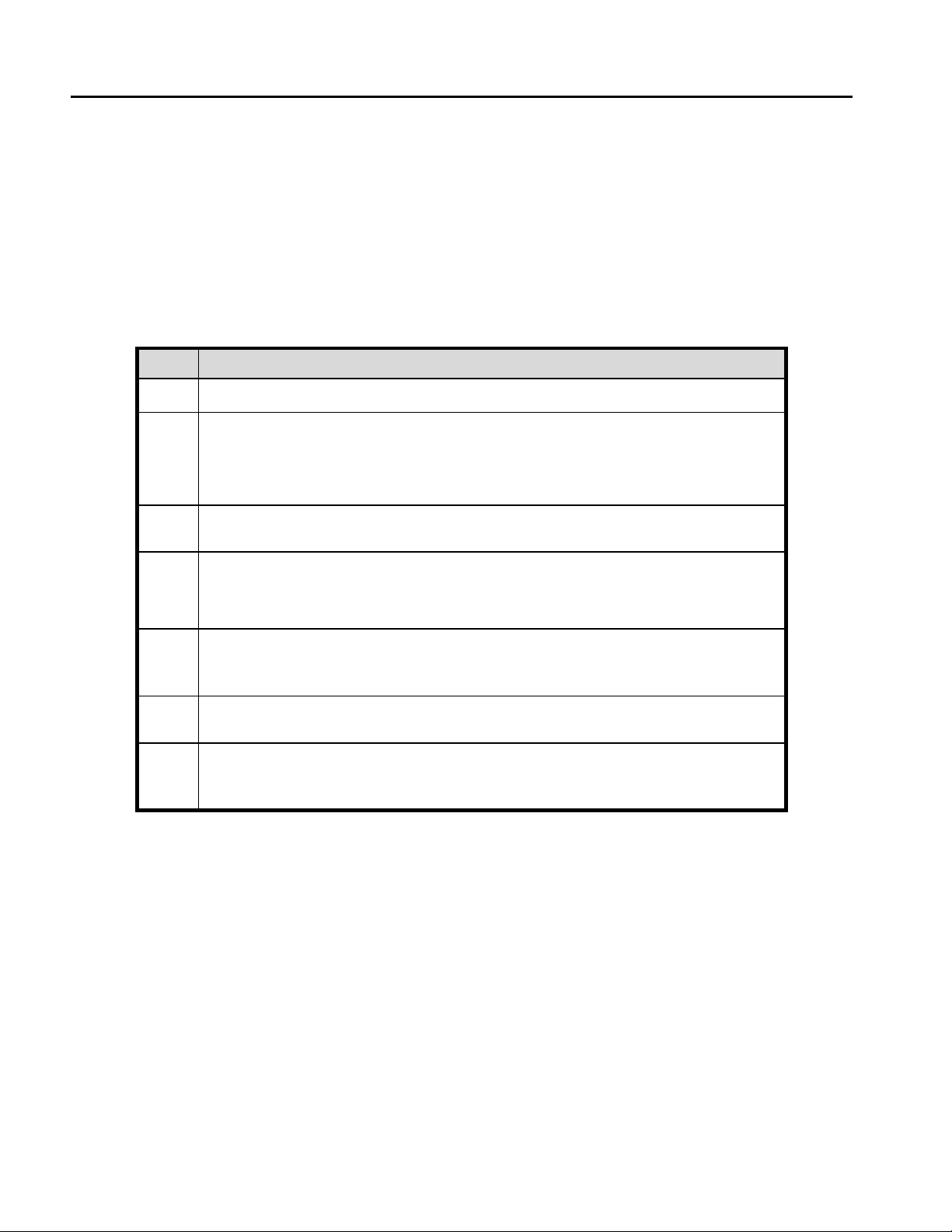

Procedure 3. Making Power Node/30 Connections

STEP ACTION

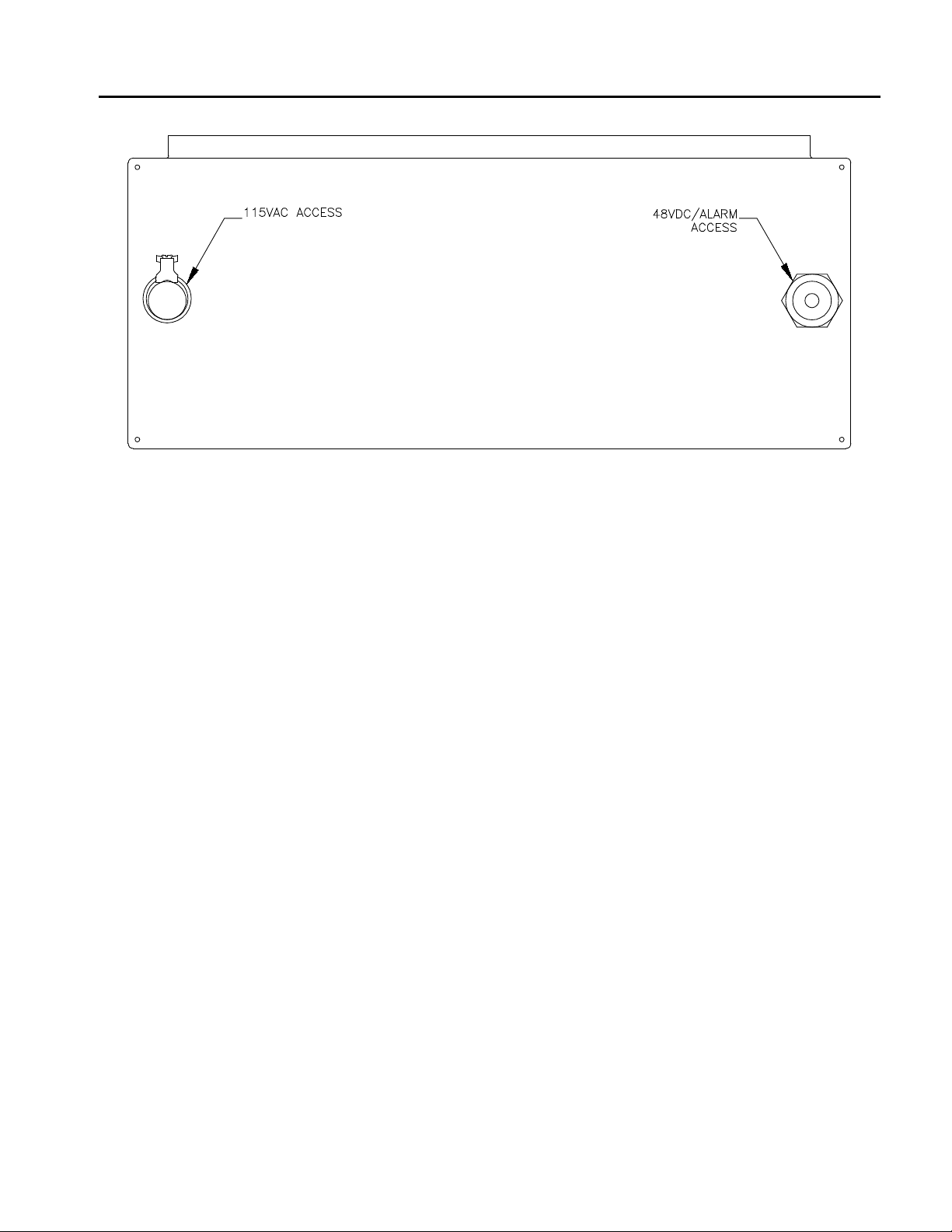

1 Route DC wiring and alarm wiring, if applicable, through the Pulsecom provided

3/4" strain-relief fitting installed in the bottom of the cabinet; see Figure 4

2 Seal the opening after routing the wires from the inside using installer provided

duct seal putty.

3 If required, locate the supplied 003484-0008 buried service wire bonding

connector in the 511542-1 Accessories Kit. Attach it to the mounting plate by

loosening the bonding connector mounting screw shown in Figure 3 and sliding

the forked tongue of the bonding connector’s mounting bar between the flat washer

and mounting plate. Tighten the screw. Then follow the instructions printed on the

bag that the 003484-0008 came in to attach the buried service wire to the bonding

connector.

4 Connect DC wiring to the –48V (1) and RTN (1) output terminals. Observe

polarity.

NOTE 1: DC load wiring gauge depends upon the distance between the

Power Node/30 and the load. Since a 0.25V drop is allowed between the

power system and the load:

* 14-gauge wire can be used when the distance is 7 feet or less.

* 12-gauge wire must be used when the distance is 8 to 11 feet.

* 10-gauge wire must be used when the distance is 12 to 17 feet.

* 8-gauge wire must be used when the distance is 18 to 25 feet.

The wire insulation type should be THHN or equivalent to provide the

required mechanical protection. Connections should be made with crimp-

on wire terminations applied with the proper tool.

NOTE 2:The Power Node/30 is equipped with a 7.5A output fuse installed

for each of two –48V outputs and one spare 7.5A fuse. If only one output

is utilized, then the unused−48V fuse must remain installed to suppress

the open-fuse alarm function.

CAUTION: Do not exceed the maximum current draw of 6 Amperes.

5 If grounding of the output return is desired, connect the spade lug end of the

supplied 511816-1 DC Output RTN ground cable (yellow/green wire) to either the

RTN (1) or RTN (2) output terminal located on the Power Supply Module. Then

route the optional DC Output RTN ground wire as shown in Figure 3, and connect

the other end to the grounding bar. Secure the wire to the panel using the supplied

cable ties.

6 Connect alarm wiring to the ALM output terminals located on the Power Supply

Module (see Figure 3).

7 Route AC wiring through the installer-provided 3/4" conduit located in the bottom

of the cabinet as shown in Figure 3.

8 Connect third wire ground to the grounding bar located on the inner left-side panel

of the Power Node/30 cabinet. Remove AC outlet box cover. Connect Hot and

Neutral wires to the terminal block as marked. Replace the cover.