SECTION 1 - INTRODUCTION Page Rev. Date

About this Manual. . . . . . . . . . . . . 41 4-2-01

Definitions. . . . . . . . . . . . . . . . . 4

Contacts . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . 4

Approvals and Standards . . . . . . . . . 51 4-2-01

Health and Safety . . . . . . . . . . . . . 5

FirstAid . . . . . . . . . . . . . . . . . . 5

FM-200® Agent Characteristics . . . . . 61 4-2-01

Agent Physical Properties . . . . . . . 6

Table 1: Toxicology/Environmental . . 6

SECTION 2 - SYSTEM COMPONENTS

System Components. . . . . . . . . . . . 7 2 11-1-01

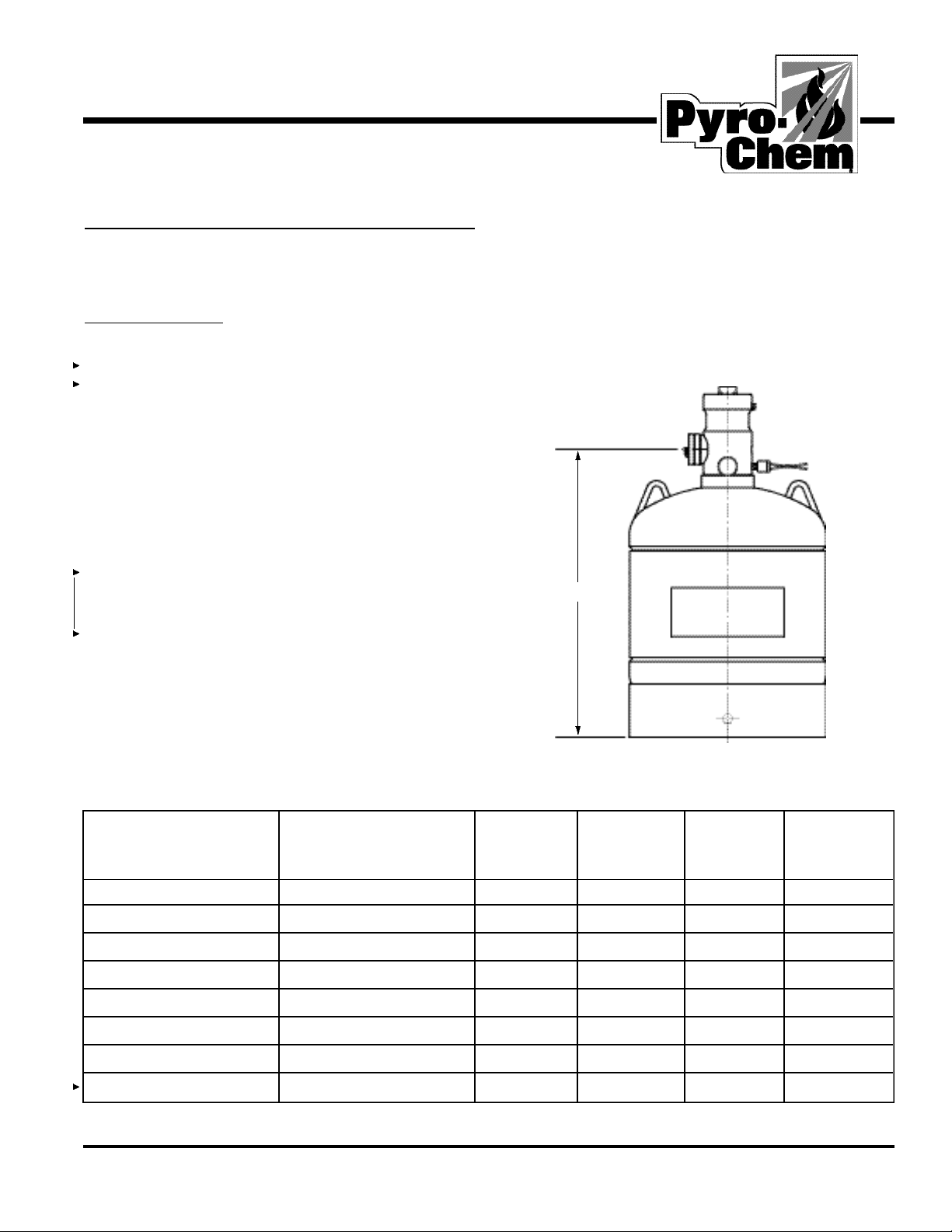

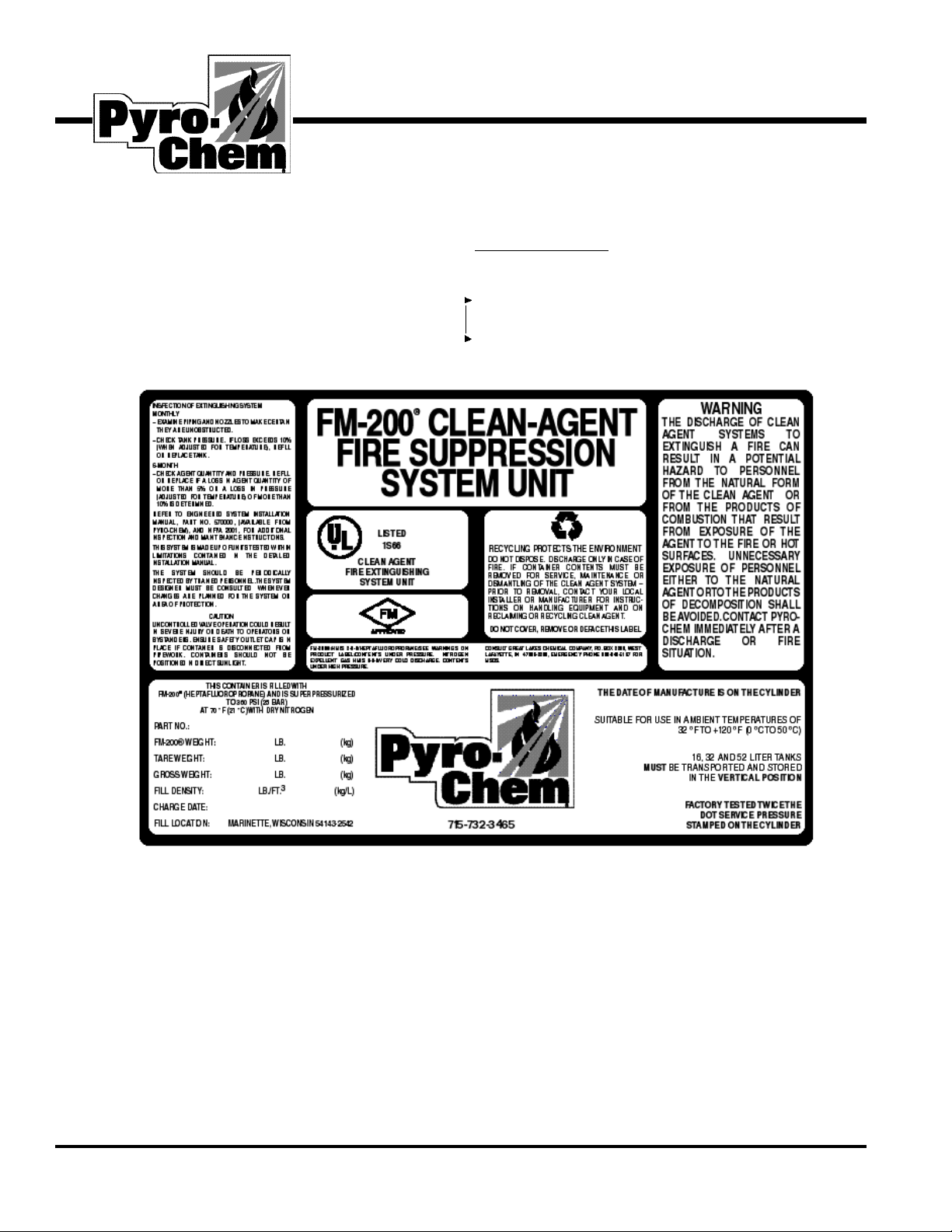

FM-200® Tank . . . . . . . . . . . . . 7

Tank Label . . . . . . . . . . . . . . . 8 2 11-1-01

Mounting Bracket. . . . . . . . . . . . 9 2 11-1-01

ValveAssembly. . . . . . . . . . . . . 9

Principle of Operation . . . . . . . . . 9

Burst Disc . . . . . . . . . . . . . . . 10 2 11-1-01

Low Pressure Switch . . . . . . . . . 10

ManualActuator. . . . . . . . . . . . 11 1 4-2-01

PneumaticActuator . . . . . . . . . . 11

Removable Electrical Actuator . . . . 11

Side Mounted Electrical Actuator. . . 12 2 11-1-01

Flexible Discharge Hose . . . . . . . 12

3 in. Discharge Hose/

Check ValveAssembly . . . . . . 12.1 New 11-1-01

3 in. Single Tank Adaptors . . . . . 12.1

3 in. Single Tank

Discharge Hose . . . . . . . . . . 12.1

SolenoidAdaptor . . . . . . . . . . . 13.......1......4-2-01

Manifold Check Valve. . . . . . . . . 13

Manifold Inlets . . . . . . . . . . . . 14 1 11-1-01

Manifold Construction . . . . . . . . 15 1 11-1-01

Manifold Construction . . . . . . . 15.1 New 11-1-01

Flexible Pilot Hose . . . . . . . . . . 16 2 11-1-01

Male Pilot Hose Connector . . . . . . 16

MaleAdaptor . . . . . . . . . . . . . 16

Male Tee. . . . . . . . . . . . . . . . 17 2 11-1-01

Male Elbow . . . . . . . . . . . . . . 17

Street Elbow. . . . . . . . . . . . . . 17

Pressure Switch . . . . . . . . . . . . 17

Discharge Nozzle . . . . . . . . . . . 18 1 11-1-01

Door Sign . . . . . . . . . . . . . . . 18

Manual Release Sign . . . . . . . . . 19 2 11-1-01

Liquid Level Measuring Device. . . . 19

Typical Manifold System . . . . . . . 20

SECTION 3 - SYSTEM DESIGN Page Rev. Date

System Design . . . . . . . . . . . . . . 21......1......4-2-01

HazardAnalysis . . . . . . . . . . . . 21

Hazard Structure. . . . . . . . . . . . 21

Hazard Volume . . . . . . . . . . . . 22......1......4-2-01

Ventilation . . . . . . . . . . . . . . . 22

Temperature . . . . . . . . . . . . . . 22

Hazard Fuels. . . . . . . . . . . . . . 22

Personnel Safety. . . . . . . . . . . . 22

Agent Quantities. . . . . . . . . . . . 22

Agent Storage . . . . . . . . . . . . . 23......1......4-2-01

Manifolds . . . . . . . . . . . . . . . 23

Agent Distribution. . . . . . . . . . . 23

Agent Flow Characteristics . . . . . . . 23

Nitrogen Superpressurization . . . . . 23

Flow in Pipe . . . . . . . . . . . . . . 23

Initial Vapor Discharge . . . . . . . . 23

Trailing Vapor Pressure . . . . . . . . 23

Nozzle Selection and Location . . . . . 24......1......4-2-01

Example: Nozzle Selection . . . . . . 24

System Design Procedure . . . . . . . . 24

Design Example - Calculations . . . . . 25......1......4-2-01

Example . . . . . . . . . . . . . . . . 25

Piping Practices . . . . . . . . . . . . . 26......1......4-2-01

SECTION 4 - FLOWCALCULATIONS

Introduction . . . . . . . . . . . . . . . 27......1......4-2-01

Table 2: Weight Calculations . . . . . 27

Table 3: Altitude Correction. . . . . . 28......1......4-2-01

FM-200®Equation Calculations. . . . . 28

Engineered Systems . . . . . . . . . . . 28

Program Parameters . . . . . . . . . . 28

Program Parameters . . . . . . . . . . 29.......1......4-2-01

Program Parameters . . . . . . . . . . 30 2 11-1-01

SECTION 5 - INSTALLATION

General Information . . . . . . . . . . . 31 2 11-1-01

Tank Installation . . . . . . . . . . . . . 31

Single Tank Installation . . . . . . . . . 32 2 11-1-01

Table 7: Bracket Mounting Heights. . 32

Multiple Tank Installation . . . . . . . . 33 2 11-1-01

Manifold Installation . . . . . . . . . 33

Table 8: Manifold Bracket

Mounting Height. . . . . . . . . . . 33

Pipe Installation . . . . . . . . . . . . . 34 2 11-1-01

Table 9: US Steel Pipe Requirements. 34

Table 10: US Fittings . . . . . . . . . 34

CONTENTS

Rev. 2 UL EX 4986 November 1, 2001