WATERAX MARK-3 Owner's Manual

03/2016 –Page 3 of 52

Contents

Important Safety Instructions.....................................................................................................................5

Personal Safety Advisory...........................................................................................................................5

Warnings ....................................................................................................................................................5

Preventing Damage to Equipment .............................................................................................................6

Introduction..................................................................................................................................................6

About this Manual.......................................................................................................................................6

About the MARK-3 .....................................................................................................................................6

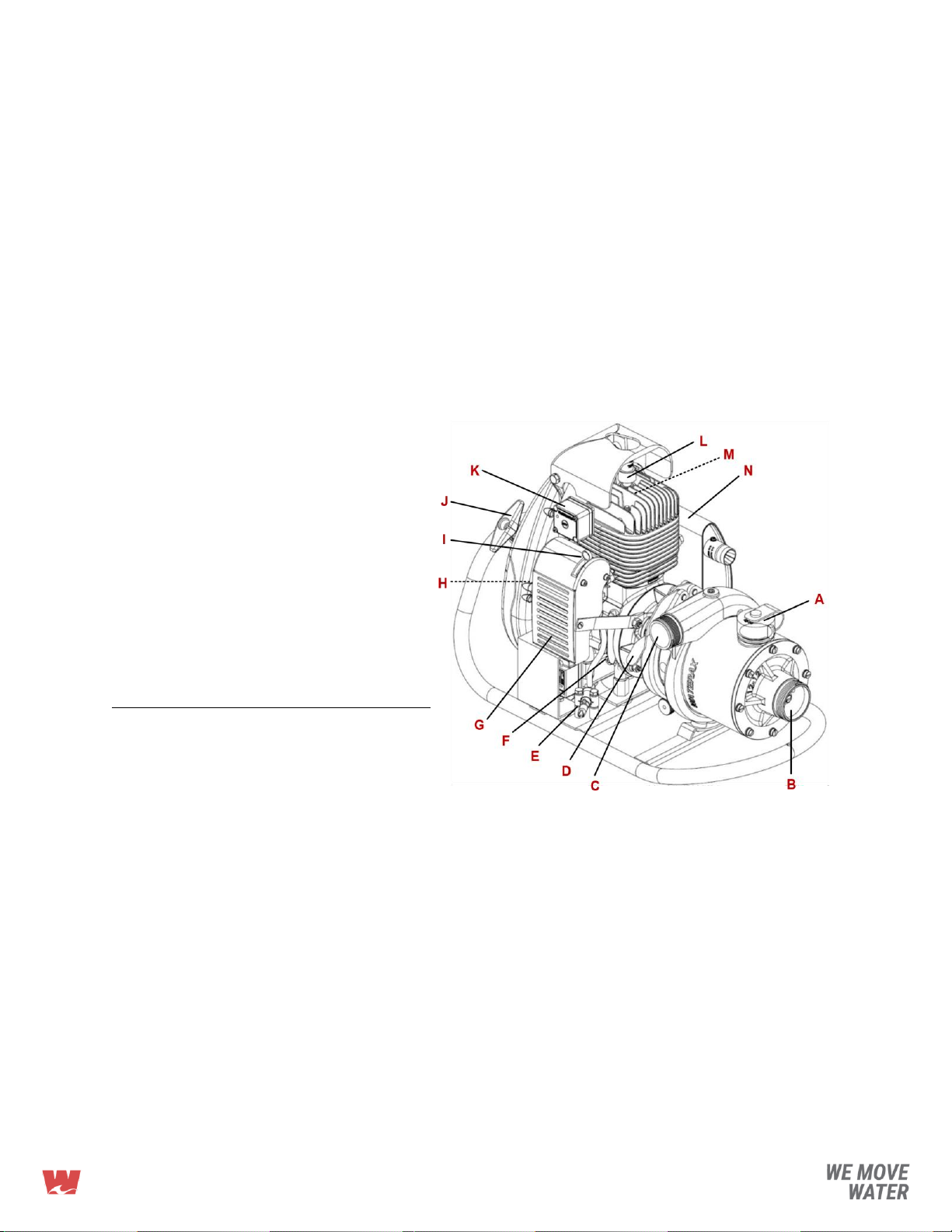

Parts Identification......................................................................................................................................7

Operating MARK-3 Series Pumps..............................................................................................................8

Pre-Operation Checklist.............................................................................................................................8

Fuel Supply.................................................................................................................................................8

Pump Connections and Priming...............................................................................................................10

Engine Startup..........................................................................................................................................11

Discharge .................................................................................................................................................12

Shutdown..................................................................................................................................................12

Operating the Digital Overspeed Switch (DOS).......................................................................................12

Cold Weather Operation...........................................................................................................................12

Removing or Attaching the Pump End.....................................................................................................13

Basic Care and Storage...........................................................................................................................13

Troubleshooting........................................................................................................................................15

Service ........................................................................................................................................................17

Carburetor ................................................................................................................................................17

Troubleshooting........................................................................................................................................21

Air Filter....................................................................................................................................................22

Fuel Line...................................................................................................................................................22

Fan Cowl (Housing)..................................................................................................................................23

Pump Clamp.............................................................................................................................................24

Rewind Starter..........................................................................................................................................25

Muffler.......................................................................................................................................................28

Frame.......................................................................................................................................................28

Digital Overspeed Switch (DOS)..............................................................................................................29

Ignition System.........................................................................................................................................30

Engine Overhaul Procedures ...................................................................................................................33

Cylinder ....................................................................................................................................................33

Cylinder Head With Decompression Switch ............................................................................................33

Crankcase ................................................................................................................................................34

Crankshaft Assembly, Pistons and Shims ...............................................................................................35

Engine Tool Kit.........................................................................................................................................35

Piston/Cylinder Matching..........................................................................................................................36

Decarbonising ..........................................................................................................................................37

Deglazing..................................................................................................................................................37

Break-in....................................................................................................................................................37

Disassembly of the Engine From the MARK-3 ........................................................................................39

Disassembly of the Engine.......................................................................................................................39

Reassembly of the Engine .......................................................................................................................39