3

TD-000487-00

K Series Service Manual

Table of Contents

1. Introduction..................................................................................................................................................................................5

1.1 Restriction of Hazardous Substances Directive (RoHS) ...................................................................................................................................................... 5

1.2 Revision history......................................................................................................................................................................................................................... 5

1.3 Service bulletins ........................................................................................................................................................................................................................ 5

1.4 Serial Numbers.......................................................................................................................................................................................................................... 5

1.5 The well-equipped service bench........................................................................................................................................................................................... 6

2. Product specification and images ................................................................................................................................................ 7

3. Firmware.......................................................................................................................................................................................8

3.1 Firmware revisions and program numbers .......................................................................................................................................................................... 8

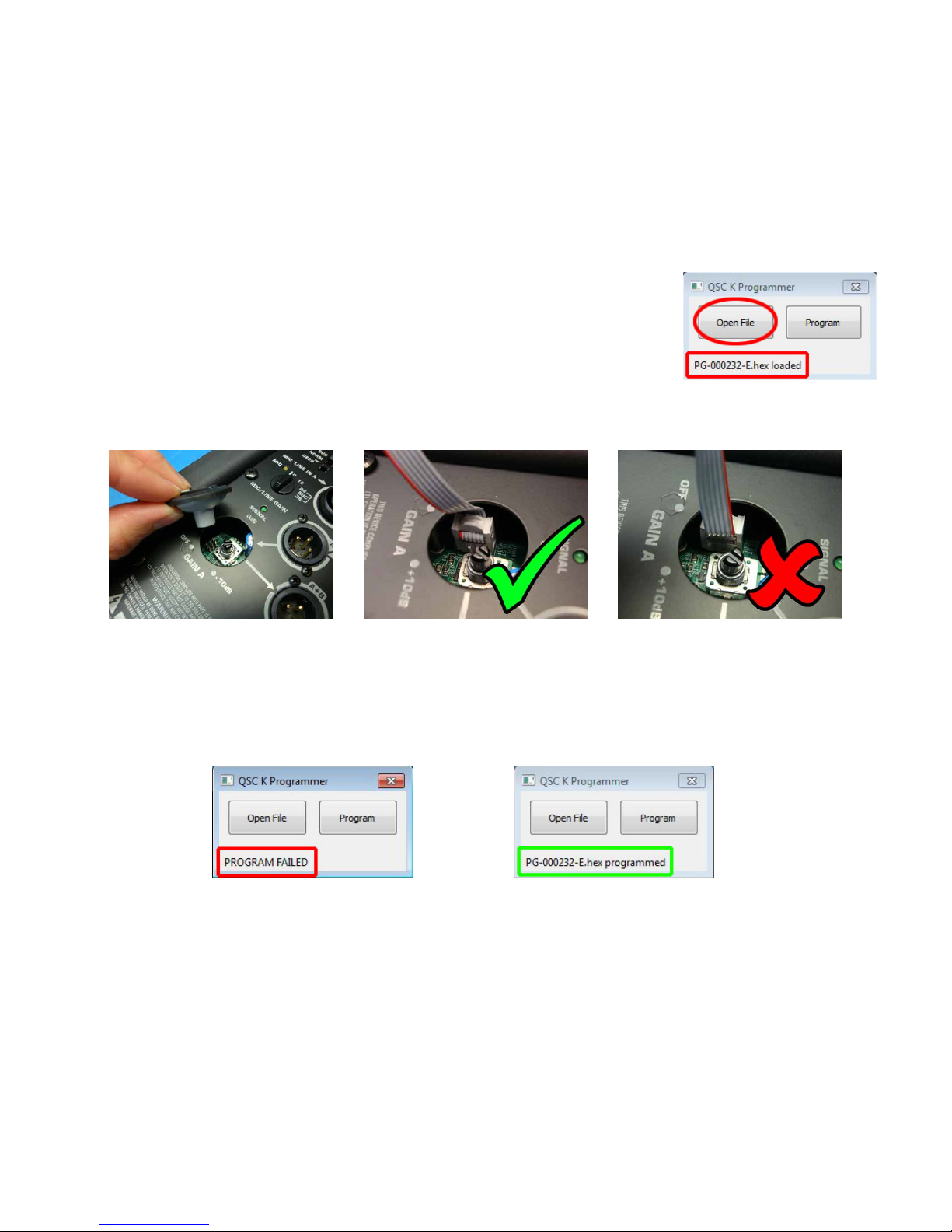

3.2 Firmware programming instructions..................................................................................................................................................................................... 9

4. Operational description ............................................................................................................................................................. 11

4.1 Series description.....................................................................................................................................................................................................................11

4.2 Top-Box Models .......................................................................................................................................................................................................................11

4.3 KSub ..........................................................................................................................................................................................................................................12

4.4 Bucket of power (BOP) amplifier module............................................................................................................................................................................12

5. Top-box disassembly instructions.............................................................................................................................................. 15

5.1 Bucket of power.......................................................................................................................................................................................................................15

5.2 Front grille ................................................................................................................................................................................................................................16

5.3 Front baffle...............................................................................................................................................................................................................................16

5.4 High frequency transducer.....................................................................................................................................................................................................17

5.5 Low frequency transducer .....................................................................................................................................................................................................18

5.6 Handles, feet, and pole mount..............................................................................................................................................................................................18

6. KSub disassembly and repair procedures .................................................................................................................................20

6.1 Bucket of power...................................................................................................................................................................................................................... 20

6.2 Low frequency transducers................................................................................................................................................................................................... 20

6.3 Handles, threaded pole mount, and casters........................................................................................................................................................................21

7. BOP disassembly and repair procedures...................................................................................................................................23

7.1 Faceplate................................................................................................................................................................................................................................... 23

7.2 PSU/amplifier board............................................................................................................................................................................................................... 24

7.3 Input/DSP board...................................................................................................................................................................................................................... 25

7.4 Power inlet, power switch, and fan ...................................................................................................................................................................................... 25

8. Testing.........................................................................................................................................................................................26

8.1 Requirements .......................................................................................................................................................................................................................... 26

8.2 Bucket of power testing......................................................................................................................................................................................................... 26

8.3 Loudspeaker testing............................................................................................................................................................................................................... 29

9. Troubleshooting guide................................................................................................................................................................ 31

9.1 General tips and tricks.............................................................................................................................................................................................................31

9.2 Line filter - broken components (BOP) ............................................................................................................................................................................... 33

9.3 Broken capacitor C45 (BOP)................................................................................................................................................................................................. 34

9.4 Input op-amp damage (BOP) ............................................................................................................................................................................................... 34

9.5 Amplifier section, MOSFET failure (BOP)............................................................................................................................................................................ 35

9.6 Power supply, MOSFET failure (BOP) ................................................................................................................................................................................. 36

9.7 Fan behavior............................................................................................................................................................................................................................ 37

9.8 Internal wiring harness.......................................................................................................................................................................................................... 37

9.9 Front LED................................................................................................................................................................................................................................. 38

9.10 Transducer issues.................................................................................................................................................................................................................. 39

9.11 Broken baffle ......................................................................................................................................................................................................................... 40

10. Service updates .......................................................................................................................................................................... 41

10.1 Inductor reinforcement, L13.................................................................................................................................................................................................41

10.2 XLR combo jacks with locking tabs .....................................................................................................................................................................................41

11. Schematics and PCB images.......................................................................................................................................................42

11.1 Schematic with notes (all models)...................................................................................................................................................................................... 42

11.2 PCB image with notes (all models) .................................................................................................................................................................................... 46

12. Component identification ..........................................................................................................................................................48

12.1 Top-box assembly components .......................................................................................................................................................................................... 48

12.2 KSub assembly components............................................................................................................................................................................................... 49

12.3 BOP components .................................................................................................................................................................................................................. 50