5

material and may require replacement every 7 to 10 years. When the Bio-COIR media has reduced in

volume by 50%, and the efuent quality fails to meet minimum regulatory requirements, it needs to be

replaced. The open cell foam media is warranted to be free from defect

for 10 years. If the media shows degradation after that time and the efu-

ent quality fails to meet minimum regulatory requirements, new media

should be added. When replacing either media, make sure to compact it

below the spray nozzle by approximately 4-6 inches to make certain that

the spray nozzles function properly.

3. Remove the spray nozzle by unsnapping the stainless steel spring from

the pipe. Clean any debris and replace them. The spray nozzle piping

can be removed at the unions and cleaned with a bottle brush or water

pressure if needed.

NOTE: If efuent samples are needed, a grab sample can be taken by placing the sample bottle below the

out fall of the recirculation device, being careful not to touch the bottle to any contaminated surface. The

efuent sample should be collected and transported according to the testing facility requirements. Efu-

ent should be clear with a slight yellow tint and should be free

from odor. Efuent results should be in accordance with NSF

Standard 40 Class 1 requirements, BOD less than 25mg/L and

TSS less than 30mg/L.

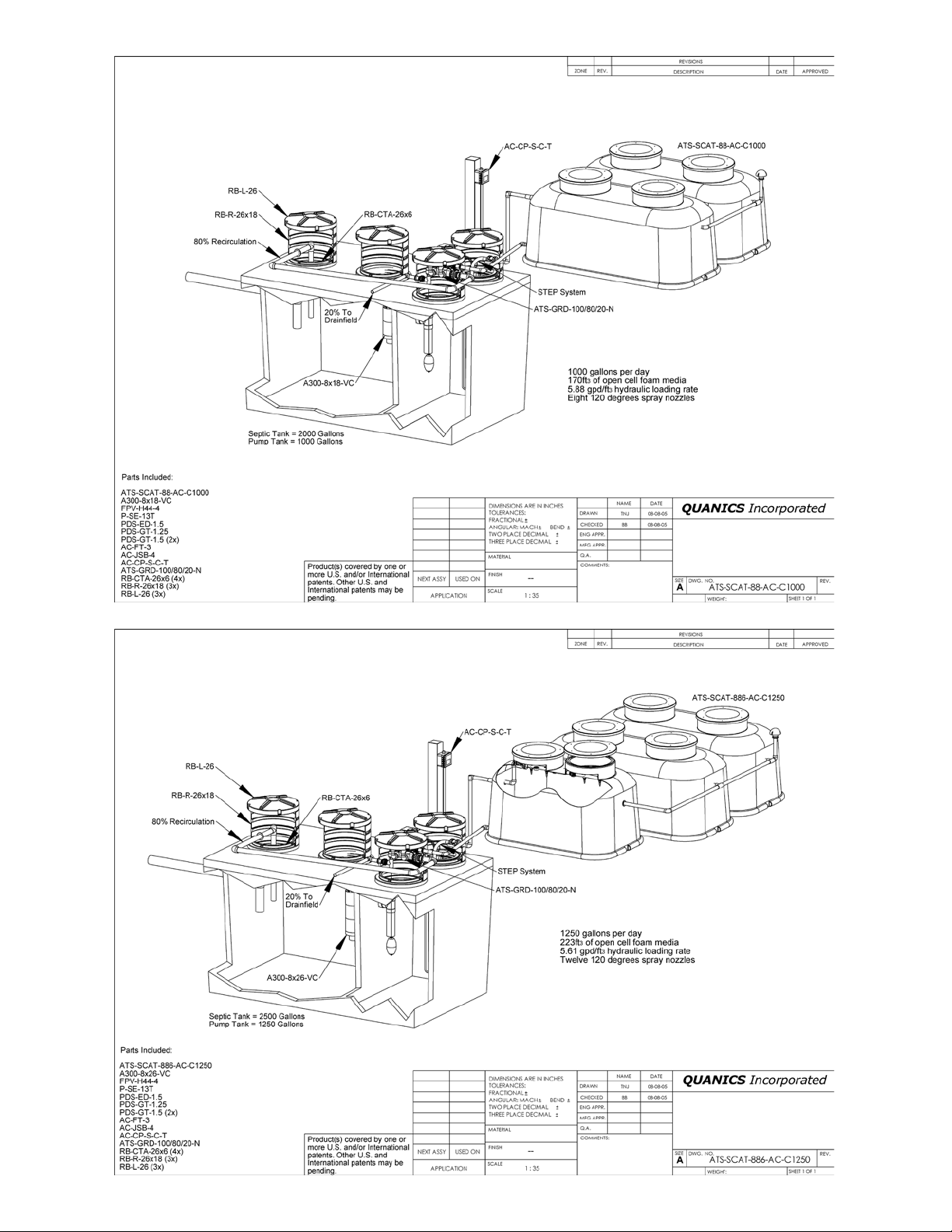

Section 7.0 Recirculation Device

1. Check to see if the stainless steel rod is moving up and

down freely. Also, check to see if the ball oat is located at

the proper level. When the ball oat is at its lowest position,

it should be located equal to or just above the on position of

the timer enable oat. (gure 1)

2. Check that the design recirculation rates are maintained by observing the discharge through all ve out

falls of the recirculation assembly. Adjust as needed by loosening the quick disconnects and leveling.

TROUBLESHOOTING GUIDE

The AeroCell®& Bio-COIR® systems will handle all domestic wastewater from your home. By the term

wastewater we are referring to rapidly biodegradable material. To keep maintenance at a minimum level

and to prevent the system from malfunctioning, the following guidelines need to be followed:

* Since aerobic bacteria are responsible for treating the wastewater, inorganic or non-rapidly biodegrad-

able materials should not be put into the system. Examples of improper items are: plastic products,

rubber products, sanitary napkins or tampons, washcloths, cigarette butts, coffee grounds, eggshells,

matches, or other non-biodegradable objects.

* Do not dispose of cooking grease or large amounts of oil into system; instead pour it into a container

and dispose of it properly.

* To minimize pump-out frequency, limit use of garbage disposals.

* Lint from lint catchers, hair, etc., should be disposed in the trash and not washed down the drain.

* Water softener backwash should not be routed through the system. Another source of disposal should

be used.

* Diapers can be rinsed out in the toilet; however, do not ush cloth or disposable diapers down the toi-

let.

* Large amounts of harsh chemicals, high sudsing detergents, disinfectants or any substance that kills bac-

teria must not be discharged into the system.

Figure 1