2007-01 C:1

Table of contents

TABLE OF CONTENTS

Preface .....................................................1:1

Loader identification ................................................ 1:1

Subframe identification............................................ 1:2

Safety instructions ..................................2:1

General information................................................. 2:1

Explanation of warning levels.................................. 2:2

Symbol explanation ................................................. 2:2

Risk factors during service ...................................... 2:3

Location of warning decals (EU) ............................. 2:5

Location of warning decals (NA) ............................. 2:6

Description...............................................3:1

Definitions................................................................ 3:1

Tool carrier............................................................... 3:2

Q Compact Valve..................................................... 3:3

Installation................................................4:1

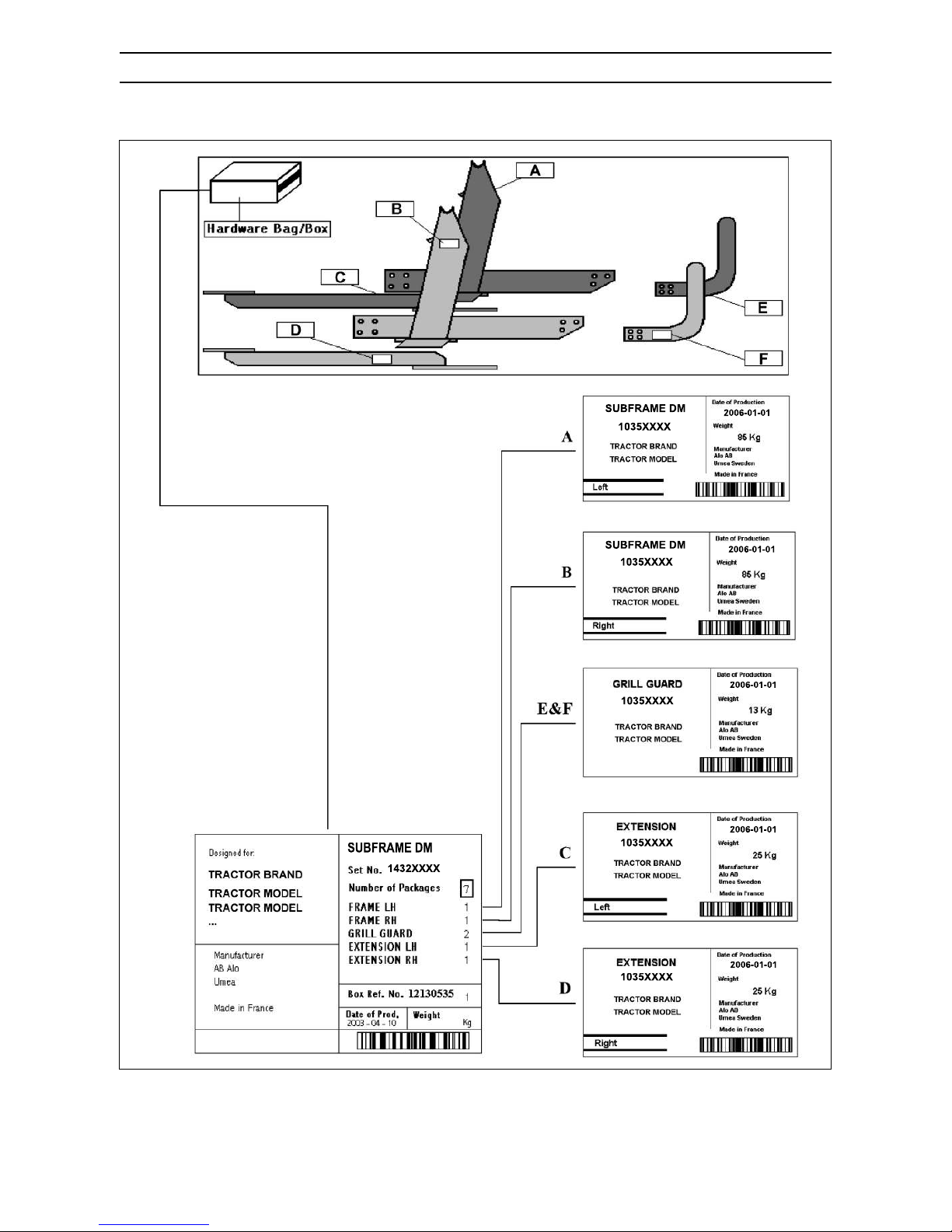

Checking the subframe hardware ........................... 4:1

Delta subframe preparation..................................... 4:2

Installing the loader ................................................ 4:3

Control cable replacement ...................................... 4:5

Mounting instructions, Safety Switch....................... 4:7

Diagram................................................................... 4:8

Electrical circuit ....................................................... 4:9

Hydraulic Circuits................................................... 4:10

Trouble shooting .....................................5:1

Trouble shooting Compact valve ............................. 5:5

Trouble shooting Electrodrive CDC ......................... 5:6

Trouble shooting internal leakage ........................... 5:9

Service......................................................6:1

Cylinder, seal assembly replacement ...................... 6:1

Seal assembly ......................................................... 6:3

Hydraulic valve ........................................................ 6:4

Thermoshock........................................................... 6:7

Replacing hose assembly in the loader beam......... 6:8

Replacing Live Third function hoses........................ 6:8

Hose removal from loader beam ............................. 6:9

Connection WEO Plug-In ...................................... 6:10

Disconnection WEO Plug-In.................................. 6:12

Touch-up painting .................................................. 6:13

Accessories .............................................7:1

Hydraulic locking ..................................................... 7:1

Loader suspension - Soft Drive/Plus Drive.............. 7:3

3rd function ........................................................... 7:10

3rd function “Pilot System” .................................... 7:13

4th function............................................................ 7:14

Lock & Go.............................................................. 7:18

Live Third Valve ..................................................... 7:19

Data...........................................................8:1