R.L.W. McCabe Lumber Co. Slatyfork Sawmill Interior User manual

History

Empty sawmills are lonely places. This kit includes all the

machineryandbasicdetailsneededtodeckouttheSlatyfork

Sawmill main floor and sawfiler's area.

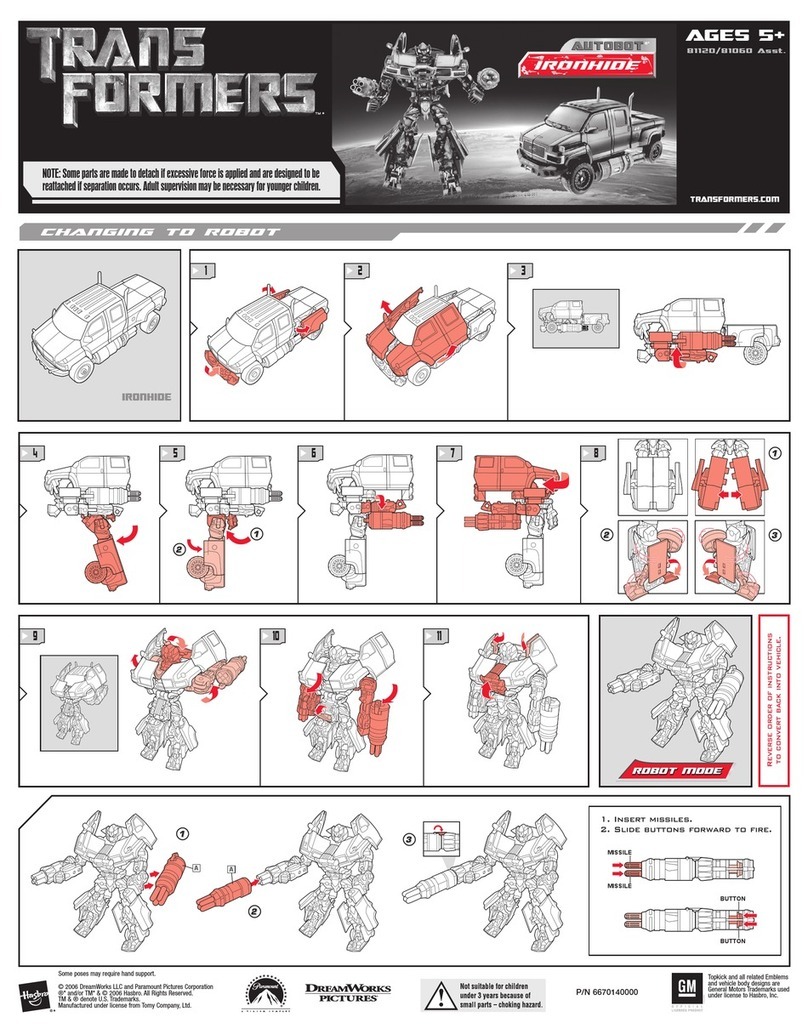

Instructions

Read the instructions completely and study the photos and

drawings before starting construction!

Warranty

All R.L.W. products are guaranteed against defects in

manufacturing and will be replaced or repaired as

determined by R.L.W. after inspection of the part. Contact

R.L.W for a return authorization prior to returning any

damaged parts. R.L.W will also replace parts that are

damaged during assembly. This part of the warranty is

voided if the kit has been modified in any way.

Drop Outs

The laser-cut sheets may look like pieces are missing, but

these holes are intentional. These waste pieces, called drop

outs, may still be clinging to the sheet and fall out when

touched. Save them for use as clutter and scraps when doing

the final detailing.

McCabe Lumber Co.

Slatyfork Sawmill Interior

#28301 N Scale

Remove the pieces from the carrier sheets with a sharp

hobby knife as they are needed, and lightly sand off the

remainder of the tabs. On the thicker pieces there is a slight

draft angle caused by the laser. This angle can be removed

with a pass or two of a fine sanding block.

Identify all the parts, checking them against the parts list. Most

wood parts have a number either on them or nearby. Extra

small parts may be included. Do not remove the parts from the

carrier yet!

Repetitive Steps

Every different procedure or method is discussed in detail

in the instructions; however, once it has been discussed, it

is not repeated in detail again.

Dimensions and Directions

Alldimensionsspecifiedinthetextareactualfeetandinches

unless used with the word “scale” before or after them.

Atmospheric Conditions

Wood and paper products are effectively live materials on

which humidity and temperature changes will change the

size of parts slightly.

R.L.W.R.L.W.

R.L.W.R.L.W.

R.L.W.

McCabe Lumber Company

2

End User Information

This kit is not intended for use by novice modelers, or

individuals under the age of 18 without the supervision of

an adult. Additionally, the modeler assumes all liability

regarding the proper use of this product or any product

suggested. The user must become familiar with the kit

instructions, and instructions on any product used to

complete this kit. Please read and follow all safety

procedures for all products used to finish this kit. Details

mayvarybetweenscalesandfromthesamplemodelshown.

Color Pallet

The basic colors are from the Floquil railroad colors line

except as noted. You may follow our suggested pallet:

Coach Green Stainless Steel

Rust Reefer Gray

Rail Tie Brown Caboose Red

Aged Concrete Antique White

Earth Grimy Black

Woodland Scenics' Mini-Scene Paint Set

Naturally, you may use any colors you wish. Just

remember that flat, dull colors are preferable to loud bright

colors for a realistically-finished model. Some colors

apparent in the photos are mixtures of two or more of the

basic colors. These mixtures are used only on detail items

and are not critical.

On the model, Coach Green was used on the machinery.

The blades, rollers and outer surfaces of the wheels were

painted Stainless Steel. Reefer Gray was used on the wood

components. Control levers are painted Caboose Red with

Grimy Black handles.

Most parts can be painted prior to assembly and most

should be painted prior to removing from the carrier sheet.

Since excess paint can cause warping, use small amounts

and paint both sides. In addition, the parts should be

airbrushed lightly with the base color rather than painted

with a brush; this will reduce the opportunity for it to warp

out of shape.A light base coat can be applied using a spray

canif an airbrush is not available. Placing under a flat weight

will also reduce warping.

Please, wear rubber gloves and a paint mask when

dealing with model paints, and work in a well-vented area.

Some of the solvents are not user-friendly!

Wood Grain and Color

Wood grain is just one of several items that is well worth

the time necessary to apply it and gives a proper look and

feel to a wood structure. It will look better if the wood grain

goes on after the initial base color coat. The addition of

wood grain will also make the nail holes on a given wall

less prominent. Please remember that wood grain should

only be applied to parts representing wood on the finished

model.

1. Use a sharp hobby knife to apply the wood grain.

2. Add two to three lines of wood grain per laser-cut board

or laser-scored board. Do this by beginning at the end of a

scale board and working to the other end in one continuous

line. Do not try to make these lines straight, but rather just

try to stay on that board. Slight waviness is exactly the result

you will want.

3. Trim the ends of some boards shorter than others and

carve away some of the material between boards.

A base coloration of thinned light tan, such as Earth, is used

for all of the wooden components in this kit not specified to

be a specific color. Some folks think it is necessary to sand

the black edges off of all of the laser-cut parts. Not true. If

you follow the suggested painting techniques, you will not

have to spend time sanding all the edges of parts before

assembly. Laser-cut edges can be base-colored with Antique

White prior to applying a light color. This will easily hide

any burned edges.

Weathering

The gray weathering wash formula used is based on

experience with laser-cut components and castings, and

should be applied after all the paint work is done. Too dark

aformulaofweatheringstainagainstarelatively-lightfinish

coat will tend to overemphasize laser-engraved nail holes.

You may wish to try this weathering wash formula:

• Obtain a one ounce empty bottle.

• Fill your bottle about 3/4 full with denatured alcohol.

• Add about 30 drops of India ink and mix well.

This Alcohol & India Ink (A&I) wash will be used on the

details of this kit. If it needs to be slightly darkened, just

add more ink. However, it is a good practice to re-wash an

object rather than use a wash which might be too dark. This

wash should be used on all of the castings after painting

them, and after final placement to mute the colors

realistically. When first applied, it will look terrible, but let

it dry before passing final judgement.

The second wash is a reddish-brown mixture. Using

the same procedure listed above, simply substitute brown

shoedye for the Indiaink to create anAlcohol&Dye(A&D)

wash. It can be used on all castings also.

An alternate method for final weathering is to use

powdered chalks. You will also need a 1” wide soft brush.

Never use this brush for anything other than chalk work.

And never wash this brush! Use your brush to dust all

exterior surfaces of the model. Brush and blow off excess

3

RLWRLW

RLWRLW

RLW

chalk. Practice on scraps prior to dusting the model. The

proper effect will dust the model slightly and will enhance

the details of the model.

Castings

The castings in our kits are made most often of metal.

However, theymayalso be injection-molded styrene orcold-

casturethane.These latter two types of parts mustbewashed

with warm soapy water instead of lacquer thinner. It is also

veryimportant to thoroughly rinse them after washing them.

Urethane parts may be sanded and filed easily, but the dust

should not be inhaled! Paint all styrene parts with Barrier

before painting them with other Floquil paints. Urethane

parts may be directly painted with Floquil paints. Several

alloys are used to produce metal parts for our kits. All the

metal parts should be handled with care as denting and

breakage may occur if they are dropped.

WARNING: The metal castings in this kit may contain

very minute levels of lead. Most of the castings in this kit

are now 99.5% or more lead free. But to be on the safe side,

keep all parts away from pets and small children, don’t lick

your fingers while building this kit, and always wash your

hands after handling the castings!.

Cleaning the metal castings is quite easy. Several

jewelers’ files and a sharp hobby knife work well for this

procedure. After you have completed the initial cleanup of

parting lines, sprues and flash, wash all the castings in

lacquer thinner, or denatured alcohol, and allow them to

dry. Handle these after washing by wearing gloves to avoid

getting them contaminated with the oils from your hands.

Sometimes the metal castings in the scene were treated

with Blacken-It according to the product instructions. The

chemical reaction between the Blacken-It and the metal

creates a very realistic weathered-metal finish.Additionally,

all metal castings can be treated in this manner to provide

greater paint adhesion.

Painting the castings is quite easy and can be

accomplished with a brush or airbrush. A good base coat

will be created by airbrushing your castings with Floquil

Earth or light gray paint. Krylon gray primer in a spray can

workswell as an alternative to an airbrush. Choose relatively

dull colors for your castings. Models tend to look more

realistic using shades such as Mud, Grimy Black, etc. by

Floquil, or similar dull shades. Rarely should you consider

using bright colors in model scenes. TheWoodland Scenics

water-base colors work well for this.

Tools Required forAssembly

Tools required for this kit: Hobby knife and sharp blades

(we buy surgical blades from the pharmacy - very sharp

and extremely thin), sanding block/emery boards, metal

straight edge/hobby scale, glues (ACC, Titebond wood

cement, Elmers White Glue, JBWeld Epoxy), paints/stains,

assorted twist drills and pin vise.

Sanding

It has been said that sanding is not necessary on a laser-cut

kit. This is not true! Proper sanding makes the difference

betweena kit simply assembled and one thatshowsthe touch

of a true master craftsman. While the laser can cut precisely,

the amount and types of glue used in assembly can alter the

fit. Dressing the edges with a quick pass of the sandpaper

will greatly improve the appearance of the finished model.

Alwayskeep an assortment of sand papers and emery boards

in your tool box. Grits ranging from 200 to 600 will be

helpful. Just about all exposed joints need to be dressed

with fine sandpaper like 600-grit. This will greatly improve

the appearance of the model.

Photos

In some of the assembly photos, the parts have not been

painted. This was intentional to help show off the different

pieces easier. In most cases, the photos show the O scale

model that has slightly different details from the HO scale

version. This will not affect the assembly of the kit. And

some photos may show parts assembled slightly out of the

recommended order.

Gluing

Titebond, a brand name of strong wood glue, is used to

assemble the large components in this kit.The residue from

this glue will have a yellow tint, so be sure to clean up any

excess. White glue is used to attach the smaller parts as this

glue will dry clear.When applying glue to the smaller parts,

it is best to use a toothpick to apply a thin layer of glue to

the back of the parts and then press them in place on the

structure. Any excess glue can be wiped off with a damp

cotton swab.

Extra Parts

With some small parts, extras are included just in case.

Strange Terms and Acronyms

N-B-W is a Nut-Bolt-Washer Casting. They are usually

made of plastic.

ACC is alphacyanoacrylate glue, i.e., superglue.

Sprue - The passage through which molten material is

introduced into a mold. During casting or molding, the

material in the sprue will solidify and needs to be removed

from the finished part.

McCabe Lumber Company

4

The main machinery components - band saws,

edgers, log carriages and tracks, and swing saws

-are packagedin plastic bagsto help keepthings

simple. Do not open these until it is time to build

and install them. Note: The specific parts list

for each of these pieces of machinery is

included in the specific section of these

instructions. The parts list in the back of the

instructions is for the remainder of the kit.

Thefloor ofthe sawmillmay bealreadyinstalled

in the mill, but this will not be a big problem.

Since the mill was designed prior to creating this interior kit, there need to be six holes added to the samill floor.

Position the cardstock template on the right side of the mill as shown below - looking at the mill from the front

- with the front of the template flush with the front corner of the floor and the laser-engraved text facing up.

Mark the holes for the edgers and ends of the log carriage track, and the triangular position marks for the ends

of the log carriage track. Remove the template, flip it over so the laser-engraved text is now facing down toward

the floor, and position it on the left side of the mill. Again, mark the two holes and the triangular position marks

for the ends of the log carriage track; ignore the holes for the edgers at this time.

Using a #60 drill, drill the inside of the corners of the six holes

only - not the triangle marks - and with a hobby knife,

remove the material from the holes.

There are already two large holes in the floor

for the bandsaws. The bandsaws and

the transfer will be the key

components for positioning

the remainder of the

parts and should be

installed first.

Front of Mill

5

RLWRLW

RLWRLW

RLW

Transfer

The four short transfer frames (A.1) glue into

the four leftmost slots in five of the long

bases(A.3) withthe basesfittinginto the

notches on the bottom of the frames.

Glue the six long transfer frames

(A.2) into the rightmost slots of the

long bases, and glue the four short

bases (A.4) into the notches on the

extensionof the longtransfer frames.

Glue the sixth long base (A.3) under

theupper sectionof

the frames.

The chain well

floors (B.9-B.11)

glue into the

transfer frames as

shown in the

drawing and photo

below. Paint the

grooved pulleys

with Grimy Black

andglue 15ofthem

into the notches on

the tops of the

transfer frames.

Glue the side rails (B.6-B.8) to the top of

the transfer frames as indicated in the

drawingand photo onpage6 after sanding

an angle on the mating ends to provide a

smooth joint. Glue the decks (B.1-B.5) to

the top of the transfer frames as shown in

the drawing and photo on page 6 after

sanding an angle on the mating ends to

provide a smooth joint. The edges of the

upper and lower decks will need to be

sanded where indicated to give a snug fit.

Whendry,sandthe outeredges ofthe rails

flush with the frames.

Place, do not yet glue, the transfer into

position on the sawmill floor (see the

drawing on page 25) and draw a line on

the outer short transfer frame at the level

of the main sawmill floor. This is the

McCabe Lumber Company

6

location of the top of the short roller support (A.15)

which should now be glued into place per the drawing

on page 5

Touch up the gray paint on the wood parts, then drill

the holes clear with a #75 drill and glue three small

N-B-Wsinto the holesonthe shortroller support(A.15)

and seven large N-B-Winto the outside notches on the

transfer frames at the ends of the grooved pulleys.

Paint the chain wells, the chain, and the dogs (G.8)

Grimy Black and allow to dry. Bend the dogs (G.8)

into a 'U' shape with the bottom being about 1/32" wide

and flat. Glue these onto the chain well

floors about three scale feet apart and keep

them in line across the transfer. To simulate

acontinuous chainloop,drape thechaininto

the 'U' of the dogs, over the center grooved

pulleys, and around the grooved pulleys on

each end. Glue the chain to the bottom of

the end pulleys.Apply a drop of glue to the

inside of each open dog and crimp closed

around the chain as shown below.

Glue the completed transfer into the mill

with the upper portion flush against the

handrail posts on the main floor and with

the lower portion resting on the lower floor

and flush against the interior wall (D.12 in

the sawmill kit).

7

RLWRLW

RLWRLW

RLW

Log Carriages and Tracks

Thecarriageframe isassembled from thetwo sides

(A.1)andthetwoends(A.2).Gluethe center beams

(A.3)intoplace.

Gluetheendsheets(D.1)overthecarriageends(A.2)

withthebottomsflush. Gluethewheelspacers(D.2)

overthe axle holeson thesides ofthe carriage.

Glue the carriage deck pieces (B.1-B.3) in place

centered on the carriage frame between the

notched areas. The seat base (C.7) glues into the

scribed area at the back of the carriage. Drill the

two holes clear with a #75 drill and glue a N-B-W

into each hole. Add the seat by gluing the back

(B.4) onto the seat base flush with the back of the

base. Glue the sides (B.5) to the base and back,

then glue the seat (B.6) onto the sides.

Glue the three headblocks to the notched areas on

top of the carriage frame. There should be a scale

foot overhang on the front side of the carriage -

that is the side facing the saw.

Drilltheaxleholesclearwitha#72drillanddrillthe

remaining14holesinthecarriagesidesandendsclear

witha#78drill.Glue a N-B-W into the four holes on each

side and the three holes across the top of the end sheets.

Touchupthepaint.

Trimtheaxlesonthebackofthewheelstoalengthoffive

scaleinches.Gluethewheelaxleintotheholeofthewheel

spacer with the wheel flush against the spacer. Cut six

lengthsof0.015wiretoascale3'-4"lengthandinsertinto

theaxle holeson theinside of theframe torepresent the

axles.

Wherethe carriageis placedon the trackdetermines the

lengthof thebrownline;cutittogivetwolengthsthat will

runfrom theend sheetsofthe carriageover therollersat

theendofthetrackandintothefloor. Gluethebrownline

into the bottom hole of the end sheet on each end of the

carriage.Theotherendswill later begluedover the roller

andunder thefloor atthe end ofthetrack.

McCabe Lumber Company

8

Log Carriage and Track Parts

(Quantity per Bag - Two Bags per Kit)

QTY MATERIAL

Set Works 1

Headblock 3

Roller 4

Nut-Bolt-Washer 16

Wheel 12

Rail 4

Spikes 40

Wire, 0.015" 2

1

Brown Line 1

A.1 Carriage Side 2 1/32Ply

A.2 Carriage End 2 1/32Ply

A.3 Carriage Center Beam 2 1/32Ply

B.1 Deck, End 2 1/32Ply

B.2 Deck, Center, Left 1 1/32Ply

B.3 Deck,Center,Right 1 1/32Ply

B.4 Seat Back 1 1/32Ply

B.5 Seat Side 2 1/32Ply

B.6 Seat 1 1/32Ply

C.1 Tie Strip, Left 1 1/16 Bass

C.2 TieStrip, Right 1 1/16 Bass

C.3 Not Used

C.4 Roller Support 8 1/32Ply

C.5 Rail Base, End 4 1/32Ply

C.6 Rail Base, Center 2 1/32Ply

C.7 Seat Base 1 1/32Ply

D.1 End Sheet 2 White Card

D.2 Wheel Spacer 12 White Card

Back View

Drilltheholesin theeightrollersupports(C.4) clearwitha#78drillandgluethemtothetiestrips(C.1,

C.2) where marked as shown in the drawing on page 5. The rollers drop in place between the

supportsandasmalllengthof0.015wireisinsertedfromthesideofthesupport to hold the roller in

place.

The two tie strips (C.1, C.2) glue together as shown in the drawing. Glue rail bases

(C.5,C.6) to thetop ofthe tiestripwith the scribedholes ontop andthe outside

edgesinsettwo scaleinches from theend ofthe ties.

Trim the railstolengthandfiletheendssmooth.Gluetheminplace

centeredon therail baseswithACC, then whendry, spikeat

theplacesindicatedbythescribedholes. Itwillbeeasier

to spike if the scribed holes are pre-drilled clear

witha#79drill.

Glue the rail base to the floor. Glue

thecarriage to therails. Wrapthe

cord over the end rollers and

glue it in place with the tail of

the cord sticking into the hole

in the floor.

9

RLWRLW

RLWRLW

RLW

Left and Right Band Saws

ThismodelwasinspiredbyonefromtheCordesmanMachineCo.This

sawdidall the hardwork of cuttingthe logs intocants.

Thebandsaw hasbeen assembledand painted abase coatof greenby

our friends in the orient. The rollers and outer surface of the wheels

shouldbepaintedsilver. Thecontrolhandleandadjustmentwheelcan

be painted black or red.

Warning! The saw blade is sharp and can cut you! No bandages

areincludedwiththiskit!

Onthe right bandsaw,position the bladeso thattheteeth are pointing

downward through the slot next to the roller and facing the band

saw frame. On the left band saw, position the blade so that the

teeth are pointing downward through the slot next to the roller and

facing away from the band saw frame as shown in the photos.

Gently bend the center of the bandsaw blade to match the radius of

the top saw wheel and shape the rest of the blade to fit the saw.

Once the blade passes through the floor it is not visible, so there is

no need to shape the bottom of the blade correctly; however, it can

be done and glued in place as shown in the photos. ACC the blade

in place after sliding the saw blade into the slot shown.

Glue the two bases of each saw together with the scribed lines of

the base on top and the holes lined up. Paint as desired.

Once the saw is glued in place on the base, the floor plate glues into

positionaround theback ofthe bandsaw tocover the large openings

inthe base. Twohandles arebent fromthe 0.010"wire andglued into

theholes in theaccess hatcheson thefloor plate.

Gluethebases,leftandrighttothesawmillmain floor with theteethof

thebladespointingtowardthejackslipendofthemillandtherollerside

ofthe bandsaw closeto the logcarriage track.

Warning! The saw blade is sharp and can cut you!

QTY MATERIAL

Band Saw 1

Blade 1

Wire,0.010" 1

Base 1 1/16 Bass

Sub-Base 1 1/16 Bass

Floor Plate 1 White Card

Band Saw Parts

(Quantity per Bag - Two Bags per Kit)

Left Band Saw

McCabe Lumber Company

10

Left Band Saw

Edgers

Theedger, orresaw, isbased upon onefrom theCorinth

Manufacturing Co. model. Its job is to rip cut the cants

into individual boards.Adjustable round blades are in

this saw and the operator moves them as needed to

produce various width boards.

The edger has been assembled and painted a base coat of

green by our friends in the orient. The rollers and outer

surface of the wheels should be painted Stainless Steel.

Apieceof0.010"wireisusedtoform

theshaftthatholdsthe blades. Cut it

to fit into the dimple on the middle

wheelof thethree-wheelside ofthe

edgerframewiththeotherendresting

ontheledgeon the single-wheel side

directlybehind the wheel'saxle.

Glue a blade hub (B.2) to each side

oftheblades (B.1)centered over thehole. Slide asmany

bladesasdesiredontothebrasswire,positionthemspaced

evenly, and glue in place. Paint this assembly Stainless

Steelandgluein place intheedgerframe.

The sheet with the various widths of bond paper strips

should be painted with Floquil Rail Brown to be used

for the belts. Choose a width close to the size of the

wheels. On the side with three drive wheels, loop the

belt around the three and glue the joint at the bottom of

the center wheel. On the other side, a belt runs over the

topof thedrive wheelandinto thefloor. Gluetheedgers

to the floor with this belt in the hole and the corners of

the edger frames inside the corner marks on the main

sawmill floor.

With the scribed lines on the outside, the roller frames

(A.1,A.2) connect together with the bottom (A.4) and

top (A.3) braces. Keep the frame assembly square and

11

RLWRLW

RLWRLW

RLW

Edger Parts

(Quantity per Bag - Two Bags per Kit)

QTY MATERIAL

Edger 1

Roller, 4' 15

Wire,0.010" 1

A.1 Roller Side, Long 2 1/32Ply

A.2 RollerSide,Short 2 1/32Ply

A.3 RollerTop Brace 6 1/32Ply

A.4 RollerBottom Brace 6 1/32Ply

B.1 Blade 6 White Card

B.2 Blade Hub 12 White Card

Belt 2 Bond Paper

sandthe edges smoothwhen dry.

Painttherollercastingsbeforegluingintoplace; theroller

can be silver and the pillow blocks on each end can be

painted green. The roller castings glue to the tops of the

frameswithonepositionedateachendandthe restspaced

approximatelyascale 24" apartbetweenthem.

Gluetherollerframestotheflooroneachsideoftheedger

as shown with the long roller spaced approximately 24

scaleinchesfrom thesloped front ofthe edgerframe and

therearrollerapproximatelynine scale inchesbehindthe

frame. The edge of the roller frames on the large wheel

side of the edger will be in line with the edger frame as

showninthephoto at theright.

McCabe Lumber Company

12

Left and Right Swing Saws

Theswing saw, a R.R. Howell Co.product,is manually

operated and is used to trim the length of the boards.

Waste falls below the rollers eventually going into the

slash burner or the fireboxes of the boilers.

With the scribed lines on the outside, the roller sides

(A.1) connect together with the bottom (A.3) and top

(A.2)braces. Keepthe frameassemblysquare andsand

the edges smooth when dry.

Determine which end of the roller assembly will have

the saw frame. The photos show it on the left so this

will be the saw on the left side of the mill; to put it on

the right simply rotate the frame (B.1) 180 degrees

beforeassembly andglue it tothe otherend of theroller

as shown in the Right Side drawing.

Left Side Right Side

Glue the frame top (B.2) to the frame (B.1). The

diagonal braces (B.3) glue between the frame and the

frame top. Sand all the edges smooth when the glue

has dried.

Glue the frame top boards (C.5) to the outside edges

and the saw hanger top boards (C.4) to the frame top

as shown in the drawing. Keep the holes in the saw

hanger top boards in line with the holes in the frame

top.

Glue the bottom joist (C.1) to the back of the frame

flush with the bottom of the frame. Glue the top joist

(C.2) to the top of the frame with the top edge of the

joist flush with the top of the top boards. Add the

diagonal brace (C.3) to the back of the frame keeping

13

RLWRLW

RLWRLW

RLW

the holes in line. Sand all the edges smooth, glue to the

roller frame assembly flush with the end, and touchup

the paint.

The swing saw has been assembled and painted a base

coat of green by our friends in the orient. The outer

surface of the wheels should be painted Stainless Steel.

Add the belt from the top wheel to the bottom wheel.

The sheet with the various widths of bond paper strips

should be painted with Floquil Rail Brown to be used

for the belts. Choose a width close to the size of the

wheels andACC it to the drive wheels. Glue the round

metal saw blade to the saw.

Glue the swing saw into the four holes on the bottom

of the frame top (B.2) as shown in the photos. Glue the

handle (D.1) to the bottom of the saw frame on the

opposite side from the blade.

Drill the 13 holes in the assembled frame clear with a

#75 drill and glue a N-B-W into each hole. Drill the

center of the drive wheel and 'V' bearing supports clear

witha#78drill.

Two 'V'bearing supportsglue tothe backof theframe as

showninthephoto on page 14. Run a scale six foot length

of0.031”wire throughthe bearingsupports and mounta

drivewheelbetweenthesupportsonthiswire.Glueabelt

in place between the outer power wheel of the saw and

thisdrivewheel.

The wire will be centered on the frame, and provides a

place for mounting an additional drive wheel that will

later connect the saw to the overhead belt drive. From

the main details bag, pull out the two small drive

wheels, one for each swing saw - these are a scale 21"

indiameter.Drillthecenterclearwitha#78drillandslide

ontothe wire-do notglue yet.

Alsofromthemaindetailsbag,pulloutthetwo'V'bearing

supports,onefor eachswing saw.Adda third 'V'bearing

support to each swing saw on the back of the frame as

shownin thephoto onpage14.

Painttherollercastingsbeforegluingintoplace; theroller

canbe StainlessSteeland thepillowblocks oneachend

can be painted Coach Green. The roller castings glue to

thetopsoftheframeswithonepositionedateachendand

therest spacedapproximatelya scale24"apart between

them.

McCabe Lumber Company

14

Swing Saw Parts

(Quantity per Bag - Two Bags per Kit)

QTY MATERIAL

Swing Saw 1

Blade 1

Roller, 4' 8

Nut-Bolt-Washer 13

Drive Wheel 1

'V' Bearing Support 2

Wire, 0.015" 1

A.1 Roller Side 2 1/32Ply

A.2 Roller Top Brace 3 1/32Ply

A.3 Roller Bottom Brace 3 1/32Ply

B.1 Frame 1 1/16Bass

B.2 Frame Top 1 1/16Bass

B.3 Frame Diagonal Brace 2 1/16Bass

C.1 Bottom Joist 1 1/64 Ply

C.2 Top Joist 1 1/64 Ply

C.3 Back Brace 1 1/64 Ply

C.4 Saw Hanger Top Board 2 1/64 Ply

C.5 Frame Top Board 2 1/64 Ply

D.1 Handle 1 1/64 Ply

Belt 2 Bond Paper

Buildthe sixhog chutes*by bendingthechutes (K.1) as

showninthedrawing.Gluethehogchutebase(J.1)tothe

insidebottom of thechute, thenglue thefour sidesof the

hogchute together. Paintthe outside ReeferGray with a

Blackinterior.One chute

willglueundereachswing

sawinsidetherollerframe.

Theotherfourhogchutes

willbeusedlater.

Theswingsawsareplaced

onthemainsawmillfloor

inlinewith thebackroller

of the edgers; the front

edge of the swing saws

should be close to the

shortedgerroller. Double

check the location using

the overhead belt frame

thatisdiscussedonpage17. Thecenter drive wheels that

willbeontheoverhead belt frame shouldlineup over the

smalldrive wheelon thebackof theswing saw. Thetop

photoonpage 12shows theswing saw atthe right.Mark

thelocationforthehogchuteandglueitandtheswingsaw

inplace,one onthe leftand one onthe right.

Back

* - The hog chutes direct scrap pieces of wood down to the hog that is on the first floor of the mill. The hog

is a grinder that makes chips of the wood before sending them to the slash burner.

15

RLWRLW

RLWRLW

RLW

Rollers

There are three long rollers and one short

roller in the kit. With the scribed lines

on the outside, the roller sides (A.11,

A.12) connect together with the bottom

(A.14) and top (A.13) braces. Keep the

frameassembly square andsand theedges

smooth when dry.

Paintthe rollercastingsbefore gluinginto

place; the roller can be silver and the

pillow blocks on each end can be painted

green. The roller castings glue to the tops

of the frames with one positioned at each

end and the rest spaced approximately a

scale 24" apart between them.

The rollers are positioned 20 scale inches

away from the log carriage track. The

short roller will rest on the roller support

that has been attached to the transfer.

Check the layout on pages 25 and 26.

Hog Chutes

Glue two previously assembled hog chutes near the end of the short

edger rollers next to the swing saws. The other two hog chutes can

be placed as desired; there is no specific location for these.

McCabe Lumber Company

16

Conveyors

Thetwoconveyorsmovethejust-cutboardsfrom

thefirstset of rollersnext tothe log carriagetrack

tothe set ofrollersthat feedinto theedgers.

Glue the conveyor posts (A.17) to the conveyor

base (A.16) as shown in the drawing.

Cuta length of 0.010"wireabout1"longandslide

it into the end post. Hold a conveyor arm (B.14)

betweentheposts and threadthe wire throughthe

arm. Addtheconveyorlever(B.15)tothewireon

one side of the center posts, and add

the remaining conveyor arms. Use a

dropofACCtolocktheleverandarms

intopositionasshown.

Gluea smallN-B-W intothe holeson

the outside posts as shown in the

drawing.

Glue the conveyors to the floor and

to the side of the long edger rollers as

shown in the photo to the right and

drawing on page 25. The arms will

rest between the rollers on the roller

frame closest to the band saw.

After installing against the edger

roller, add a control wire that will run

from the conveyor lever into a hole

that needs to be drilled in the floor

underthelever.Cutapieceof.5"0.010"

wire and bend 1/32" on one end to a

900angle forming an 'L' shape. Use a

#50drilltocreateaholeinthefloorbelow

theconveyor lever, insert thebentportion

intotheholeintheconveyorleverwiththe

remaininginsertedintotheholeinthefloor.

17

RLWRLW

RLWRLW

RLW

Drive Belts

The bulk of the belt drive system for the Slatyfork

Sawmill is on the first floor of the mill hidden under

the main sawmill floor. The swing saws need power

thatmust bebrought upfrom under thefloor andacross

the ceiling.

Form a belt shaft by gluing the

three belt walls (B.17-B.19)

together. Paint the exterior to

match the interior color of the

sawmill and the interior black.

Glueit tothe lower flooragainst

the outside wall as shown in the

drawing on page 25 and the

photo below.

Main Floor Details

The various pieces of machinery need to be controlled

and, in the Slatyfork Sawmill, this is done by levers

that control the belt drive below the main floor.

The levers are painted red and

the handles can be painted

black. Glue the control levers

(H.1) into the lever bases (A.7,

A.8). A small N-B-W glues

into the holes on each side of

the base, and the bases glue to

the sawmill floor as indicated

inthe floordrawing onpage 25.

The large drive wheels of the

edgers have a safety barrier.

Glue the wheel safety rails

(F.13) to the wheel safety post

(D.3) as shown in the photo below. Glue the completed

barrier into the belt slot beside the edgers.

There are several sizes of cut lumber (A.9, I.1, I.2)

included to be placed on the rollers and transfer. Sand

the laser burn off the sides before gluing in place.

Assembleand paintthe figures. Gluethese guys around

the main floor as desired. Add whatever trash, slash,

and sawdust is desired at this time to the machinery

and floor.

McCabe Lumber Company

18

The overhead belt frame for the swing saws will mount on the inside walls

ofthe sawmill. Gluethe beltframe hangersupport (B.20)tothe bottom

of the belt frame hanger (E.3) with three edges flush. The part of

the hanger support that extends out from the hanger will

glue under the top rail of the sawmill wall frame just

over the last set of main floor windows. The

vertical belt wheel, indicated in the drawing

below, should be over the belt shaft just

installed on the lower floor.

Sand the top of the ends of

the belt frame (E.2) to

an angle that will

clear the roof when

installedin the mill.

Test the fit and

resand, if needed,

before proceeding.

Glue the belt frame

braces (B.16) over

the crossmembers

of the belt frame

(E.2). Drill the

holes in the braces

clear with a #75

drill and glue a small N-B-W into each hole.

Turn the frame over, placing the N-B-Ws on

the workbench, and using the holes as guides,

gluea 'V'bearing supportto the frameas shown

in the photo below after drilling the hole clear

witha#78 drill. Runninga lengthof 0.015” wire

Bottom view of the O scale Belt Frame. The

vertical belt wheel is in the upper left corner.

19

RLWRLW

RLWRLW

RLW

throughthebearingsupportswillhelpkeeptheminalignment

whilegluing.

Drillthecentersofthesevenlarge drive wheels clear with

a #78 drill. Cut two lengths of 0.015" wire a scale 7.5'

longandcutonelengthascale5'long. Filetheendssmooth,

and use them to install the drive wheels as shown in the

photoonpage18. Center thewheelsbetween the bearing

supports and glue all the outer wheels in place; the two

center wheels will need to be positioned over the drive

wheelsoftheswingsawsbeforegluingintoplace.

The sheet with the various widths of bond paper strips

should be painted with Floquil Rail Brown to be used

for the belts. Choose a width close to the size of the

wheels. Belts need to be installed on the two outer sets

of wheels as shown in the photo on page 18. Two

lengths of belt may need to be glued together end-to-

end to make it long enough to fit; a small overlap will

work. Glue to the wheels with ACC.

The vertical belt will be glued to the end drive wheel

and trimmed to fit inside the belt shaft without hitting

the floor. Glue it to the drive wheel and test the fit

beforetrimming.Thelower endscan begluedto asmall

scrap of wood to help keep them straight.

Glue the belt frame into the notches of the belt frame

hangers (E.3) with the vertical belt inside the belt shaft.

Position the center wheels over the drive wheels of the

swingsaws andglue themin place. Beltsneed tobe run

from these center drive wheels down to the small drive

wheelsonthe swing saws. It will beeasiertosimplyform

twobeltsinto'U' shapes thengluethemto the smalldrive

wheels on the swing saws. The upper ends can then be

rolledaroundthelargedrivewheelsonthebelt frame and

gluedinplace.

Sawfiler'sFloor

Duringthesawmillassembly,thesafetyrailingsshouldhave

beenadded around theopenings inthe sawfiler'sfloor as

shownbelow. Ifnot, doso now!

Theband sawblades arehoisted up fromthe mainfloor

for sharpening and repair. TheA-frame hoists are now

added over the openings as follows. Glue the hoist

beams (A.6) to the tops of the hoist frames (A.5).

Glue a hoist pulley bracket (B.13) into one slot on the

bottom of the hoist beam, place a grooved pulley into

McCabe Lumber Company

20

thehole,andgluethesecondbracket(B.13)intotheother

slot.Glue a smallN-B.Winto theholes onthe outsideof

thepulleybrackets.

Glue the upper brace (F.9) and the lower brace (F.8) to

each side of the hoist frame. Glue each completed hoist

inserted into the opening in the sawfiler floor.

Cuttwo1"lengthsofchain.Runoneovereachpulley,and

secure one end to one of the safety railing posts on the

open end of the hoist opening as shown in the photo on

page 22.

Assemblethe two

workbenches by

gluinglegs(A.10)

into the notches

of the sub-tops

(B.12).Before the

gluedries, inserta

shelf (C.2), board

side up, between

the legs. When

the legs are dry,

glue these shelves to the cross boards of the legs. The

tops (C.1) glue down to the assembly with the back

flush with the rear edge of the frame and the scribed

side up. Stain these with either oak stain or paint, and

weather heavily with gray washes.

Paint the grinders orange with dark gray wheels and

glue to one end of each workbench. Paint the laser-cut

squares, triangles, and files (G.4, G.5, G.6, G.7) Grimy

Black and glue to the workbenches. The tool set

castings,hammers, lubecans,tongs, blowtorches, etc.,

and assorted cans & junk can be painted as desired and

added to the workbenches or the shelves. Glue the

workbenches about 3/64" out from the side walls of

the sawfiler's area.

The two shelving units are

assembled using three

vertical sides (C.5) - the top

of these has a notch - and

four shelves (F.4); start by

gluing the shelves to the

center vertical piece first,

then adding the other two

pieces. Glue in place 3/64"

outfrom theback wall nextto

thedoor.

Gluea bladehub (G.2)to each

side of the round saw blades

(G.1) centered over the hole.

Paintthese silverand weather

with rust. Glue around the

sawfiler's area.

Assemble the blade holders by gluing

thebase (F.1) intothe slot onthe bottom

of the holder (F.2).

Glue the ends of the band saw blades

(G.3) together to form loops. Glue six

or more blade holders to each of two of

the blades and glue these into the open

areas of the sawfiler's floor. The other

two blades can be stacked on the floor

out of the way or tossed around the

outside of the mill. The extra blade holders can be set

aside as shown below.

Assembletheladderbygluingtherungs(C.4)intotheslots

on the rails (C.3) to form the ladder as follows. Glue a

rungintotheendslotstotietherailstogether.Allowthese

todrycompletely,and add theremainingrungs.When all

are dry, sand the sides

of the rails smooth,

paintandlayaroundthe

areaagainstawall.

The sawhorses are

assembled by gluing

the beams (D.2) into

the notch at the top of

thelegs(D.1).Thereare

This manual suits for next models

1

Popular Toy manuals by other brands

Colorbok

Colorbok You Design It Stepping Stone Easy Step-By-Step Instructions

JUNIOR HOBBY

JUNIOR HOBBY Top RAIDERS wave shark Instruction

roco

roco 70075 operating manual

Lightscale

Lightscale One Build manual

Fisher-Price

Fisher-Price V4436 manual

Fisher-Price

Fisher-Price FORD F-150 L6348 Owner's manual & assembly instructions