Congratulations on choosing a Rainbow Colour Changers product! We thank you for your custom.

Please note that this product has been designed and made with total quality to ensure excellent

performance and best meet your expectations and requirements.

It is essential to know the information and comply with the instructions given in this manual in order

to ensure the fitting is installed, used and serviced correctly and safely.

Carefully read this instruction manual in its entirety and keep it safe

for future reference! Please hand this manual over if you sell or give this

product to somebody else.

General

Rainbow Colour Changers products are intended for professional use and should only be used by

qualified personnel or under their supervision.

Follow all cautions and warnings indicated on the unit.

After unpacking this product, please check if the device is intact. If this is not the case, please

contact the support service.

Rainbow Colour Changers

An der Talle 26-28

D-33102 Paderborn, Germany

Phone: +49 (0)52 51/14 092-28

Fax: +49 (0)52 51/14 092-90

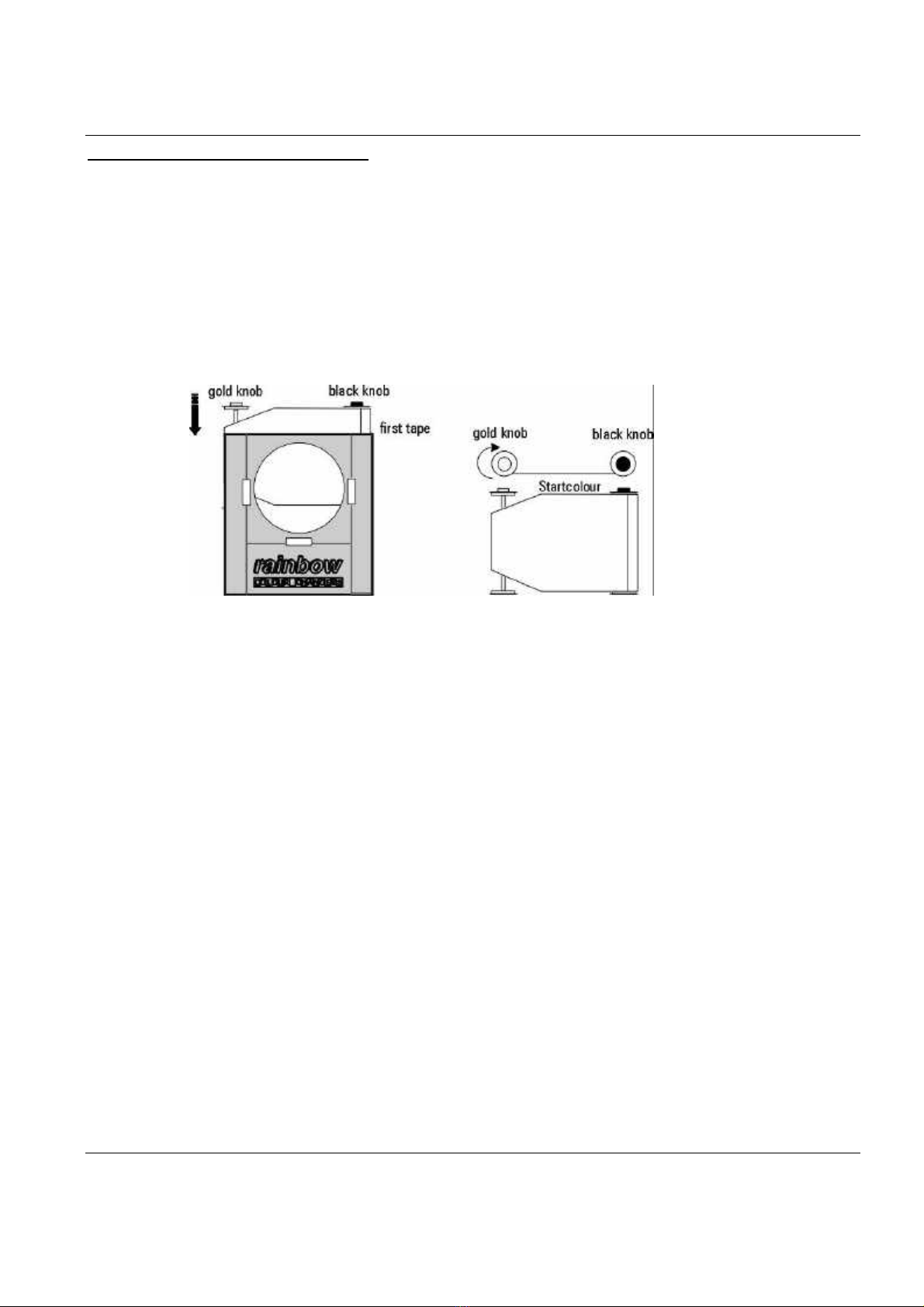

Installation

Make sure all parts for fixing the colour changer are correct.

Make sure the fixture is stable before positioning the Colour Changer.

Do not fix this device on or near flammable surfaces.

Usage

This product is designed for indoor use only. For the fitting to operate well and reliably, it should

not be used in humid environments. The ambient temperature should not exceed 40°C (104°F) or

fall below 0°C (32°F).

Avoid any liquids or metallic items entering the unit.

Ensure adequate ventilation and do not block or cover any ventilation slots in the device – they

guarantee the reliable functioning of the unit and protect it against overheating.

The scroller may only be used in its standard position, which is +/- 60° from horizontal.

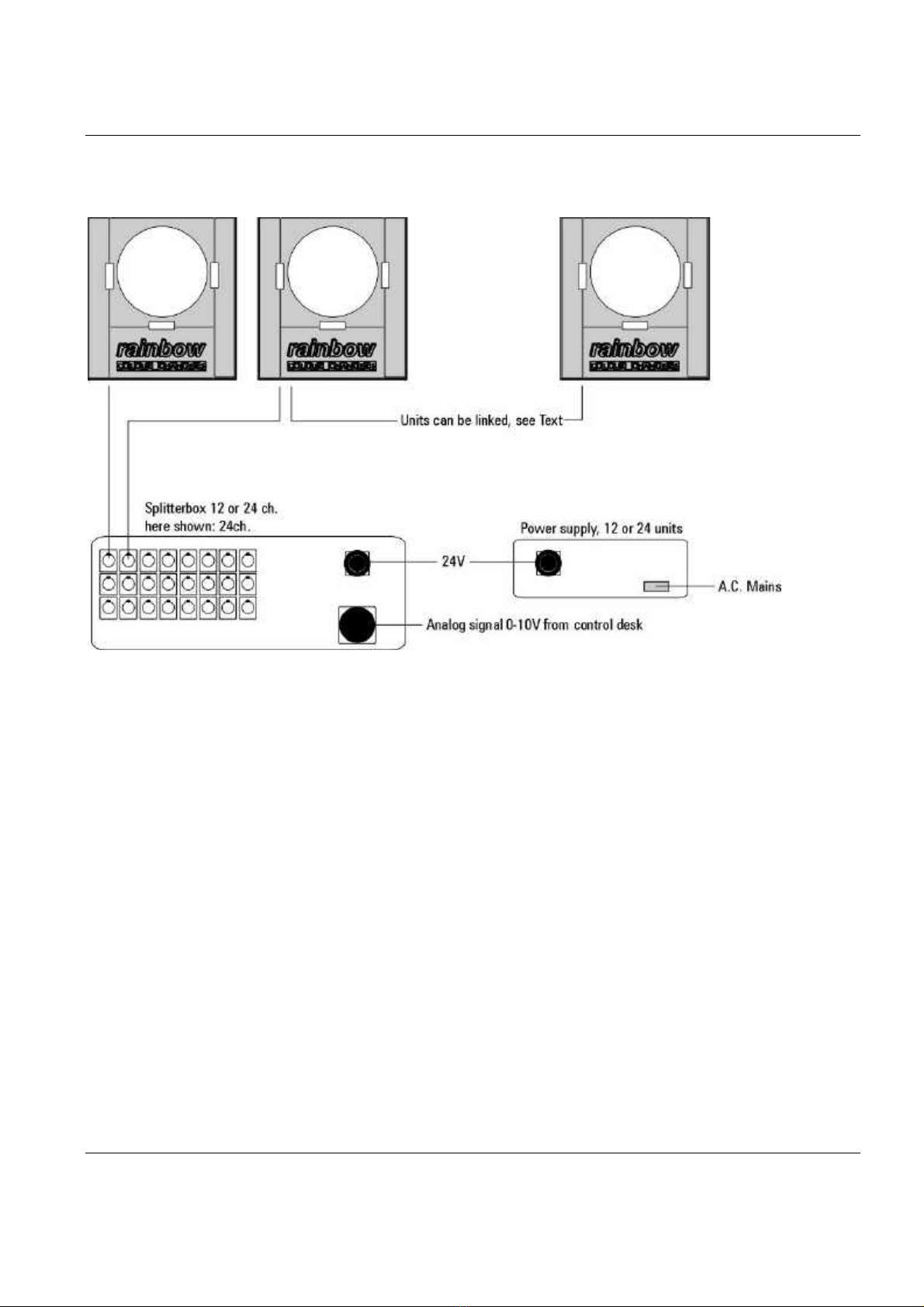

The colour changer may only be put into operation with original Rainbow Colour Changer power

supply units (PSU).

Check that the mains frequency and voltage correspond to those for which the PSU is designed as

given on the surface label of the PSU. Refer to the manual about the max. amount of scrollers to be

connected

Maintenance

All service work should be exclusively performed by qualified personnel.

Do not dismantle the scroller or modify it yourself.

Before starting any maintenance work or cleaning the scroller, remove the power from the PSU.

The surface of the device may heat up due to the luminaire used. Please let the scroller cool down

before touching it.

Rainbow Colour Changers GmbH disclaims all liability for damage to the fitting or to other property or

persons deriving from installation, use and maintenance that have not been carried out in conformity

with this instructions manual, which must always accompany the fitting.

Rainbow Colour Changers GmbH reserves the right to modify the characteristics stated in this

instructions manual at any time and without prior notice.