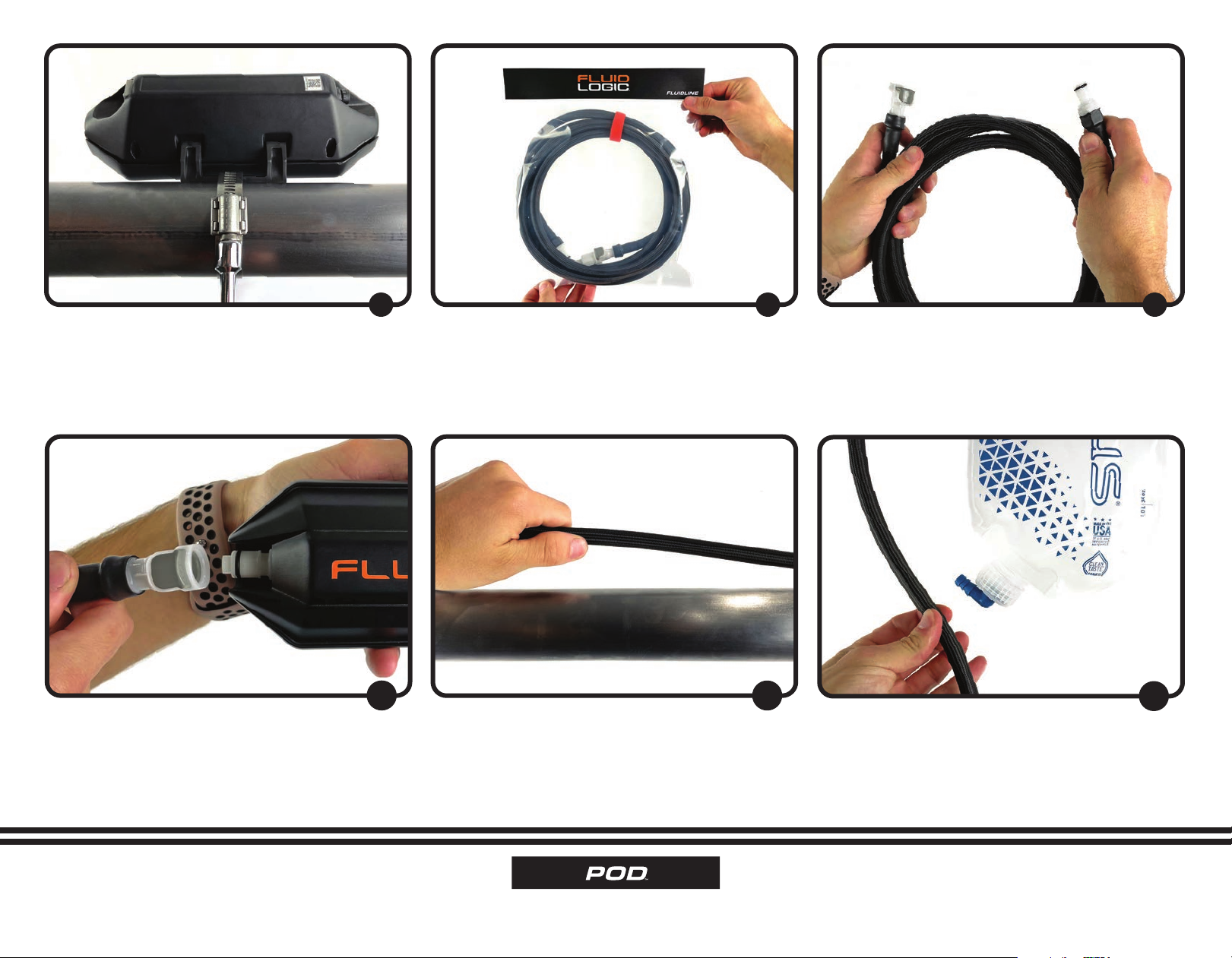

INSTALLATION INSTRUCTIONS • PRODUCT SAFETY & LEGAL DISCLAIMER

DESIGNEDINCALIFORNIA/PATENTFLUIDLOGICCOM/PATENTS•RAINMAKERSOLUTIONSINCELSEGUNDOCA

FLUIDLOGICCOMANDTHECIRCUMFERENTIALBANDSAROUNDTHEFLUIDLOGICCOMQUICKCONNECTSARE

TRADEMARKSOFRAINMAKERSOLUTIONSINC•MADEINUSA•FLUIDLOGICCOM

IMPORTANT READ ALL INSTRUCTIONS CAREFULLY BEFORE INSTALLING, FAILURE TO DO SO MAY CAUSE PERSONAL INJURY OR DAMAGE TO PRODUCT AND/OR PROPERTY.

INJURY HAZARD

• Please complete a shop and tool inspection prior to beginning the installation.

• Always make sure you have a clean, dry and well lit work area.

• Always remove jewelry, loose fitting clothing and wear protective gloves and eye

protection.

• Always use extreme caution when jacking or raising a vehicle for work. Set the

emergency brake and use tire/wheel blocks and jack stands. Refer to the vehicle

manufacturer hand book. Utilize the vehicle manufacturer’s designated liing points.

• Always use appropriate and adequate care in liing parts during disassembly and

installation. Seek help in liing heavy or large items into place. Utilize jack stands and or

liing devices when liing the vehicle.

• Always ensure products are secure during disassembly and installation.

• Always wear eye protection and take steps to protect any exposed skin during the

installations. Drilling, cutting and grinding plastic and metal may create flying particles

that can cause injury.

• Always use extreme caution when drilling, cutting and or grinding on a vehicle.

Thoroughly inspect the area to be drilled, on both sides of material, prior to

modification and relocate any objects that may become damaged.

• Always assemble and tighten all fasteners per the installation instructions.

• Always route electrical cables carefully. Avoid moving parts, parts that may become

hot and rough, or sharp edges.

• Always insulate and protect all exposed wiring and electrical connections.

• Review the product packaging and contents prior to beginning the installation. Take

care when opening the packaging and removing items. If a return is necessary it is best

to return the product in its original packaging if possible.

• This instruction guide is provided as a GENERAL installation guide, some vehicles vary

dimensionally and may require additional steps. If at any time you have any concerns

about your ability to install this product please reach out to a qualified installation

specialist to provide professional installation of this product.

• Test fit the product on the vehicle prior to any third party modifications and/or

finishing. The manufacturer and/or retailer do not accept responsibility for third party

charges, labor and/or third part replacement modifications. Some modifications may

void the factory warranty.

• Exercise due-diligence when installing this product. The manufacturer and retailers

of this product do not accept any responsibility for vehicle damage or personal injury

resulting from the installation of this product. Careless installation and operation can

result in serious injury or equipment damage.

• This product is for general off-highway use. All liability for installation and use rests

with the owner/operator.

• INSTALLER: Once installation is complete, please return this guide along with other

documentation included in this product back to the consumer for future reference. The

manufacturer/retailers of this product do not guarantee this particular version will be

available at a later date.