CONTENTS

..................................

MOTORCYCLE SAFE RIDING

2

Safe Riding Rules

.........................................................................

2

...........................................................................

Protective Cloths 2

Refitting ......................................................................................2

Loading and Accessories

..............................................................

3

DESCRlPTION

...................................................................

3

................................................................................

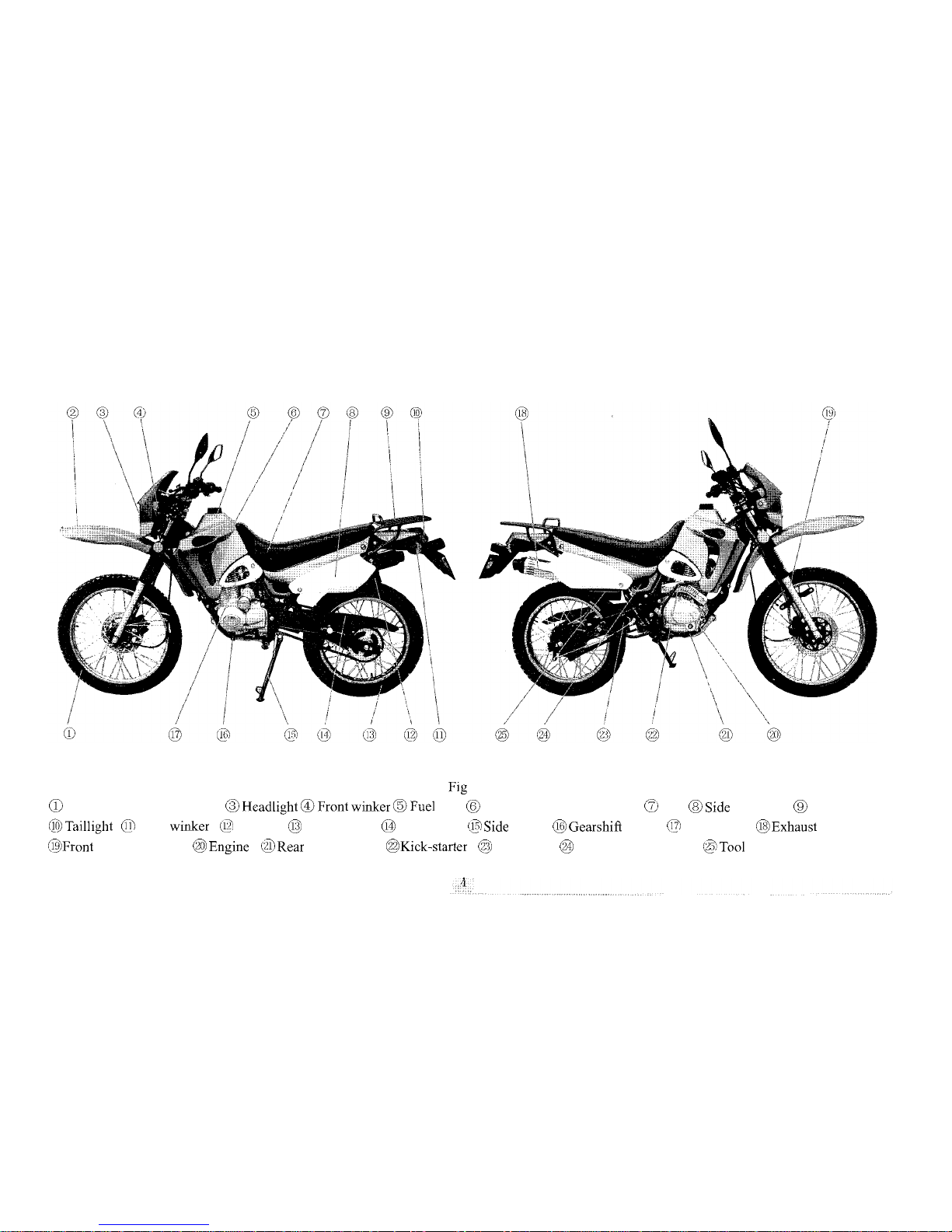

Parts Location 3

VIN

Record

...................................................................................

5

............................................................

Instruments and Indicators 5

...............................................................................

Ignition Switch 5

................................................................

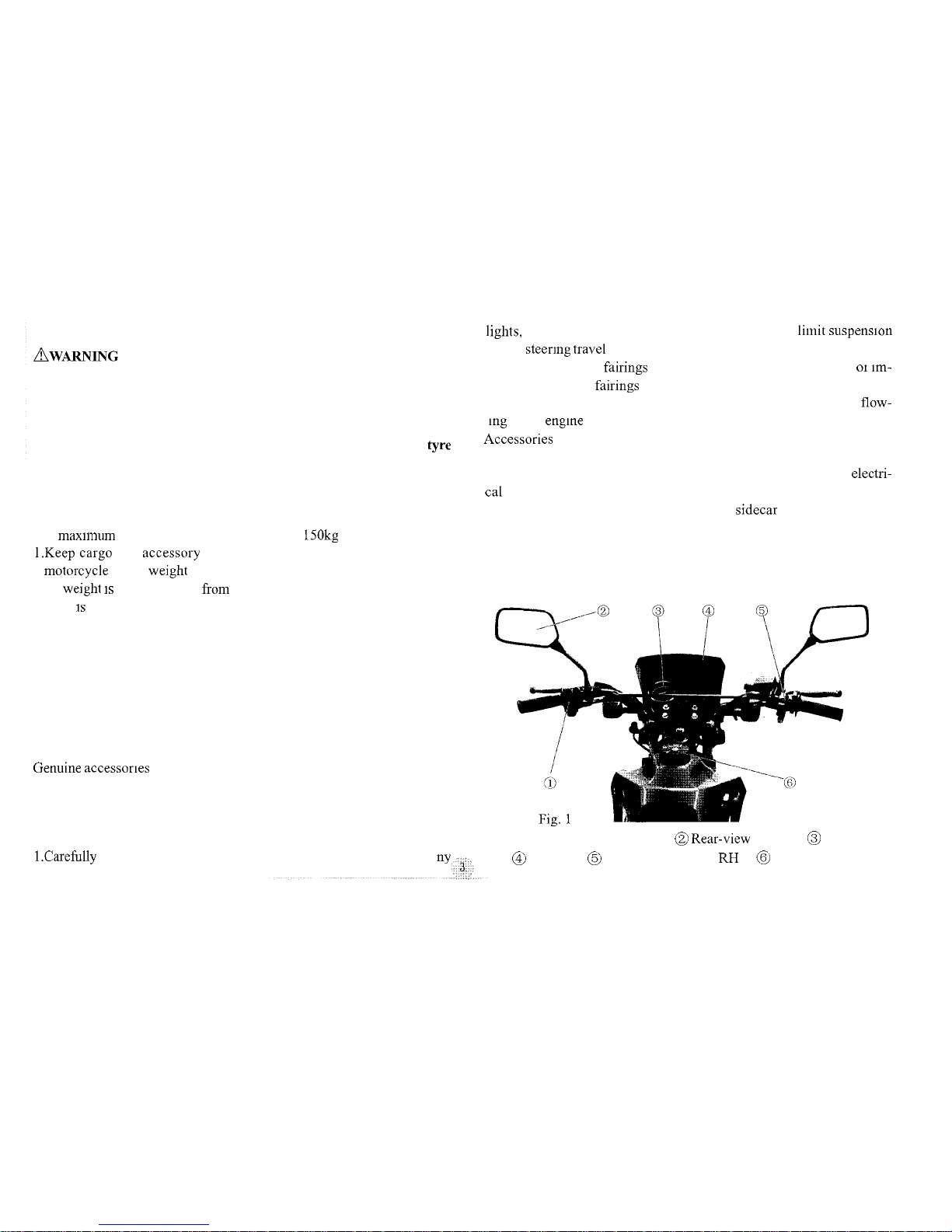

Left Handlebar Controls 5

Right Handlebar Controls.........................................................5

........................................................................

Fuel and Fuel Tank 5

Fuel Cock

......................................................................................

6

Lubricating Oil

..............................................................................

6

Tyres

..............................................................................................

7

.........................................................

OPERATIONGUIDE

7

........................................................................

Pre

-

ride Inspection 7

........................................................................

Starting the Engine

8

.

.

....................................................................................

Brealung-~n

8

Riding

............................................................................................

8

Parking

...........................................................................................

9

..................................................................

MAINTENANCE

9

...................................................................

Maintenance Schedule 9

..........................................................................................Tool Kit 10

...........................................

Check and Change of Lubricating Oil 10

.....................................................................................Spark Plug 11

...........................................................

Clear away Deposit Carbon 11

....................................................................................

Air Cleaner 11

..............................................

Check Leaks along Air Supply Line 12

.........................................................................

Throttle Operation 12

......................................................................................

Idle Speed

12

....................................................................

Adjustment of Clutch 12

...................................................................................

Drive Chain 12

....................................................

Check of Front Shock Absorber 13

.....................................................

Check of Rear Shock Absorber 13

........................................

Check and Adjustment of Front Brake 13

.............................................................

Adjustment of Rear Brake 14

Exhaust Muffler

.............................................................................

I5

Battery ...........................................................................................I5

...............................................................................................

Fuse 15

.............................................................................

Troubleshooting 15

.........................................................................................Cleaning 15

................................................................................

Storage Guide

16

...................................................................

Removal from Storage 16

..............................................................

SPECIFICATIONS

17

...................................................

ELECTRlC DIAGRAM

19