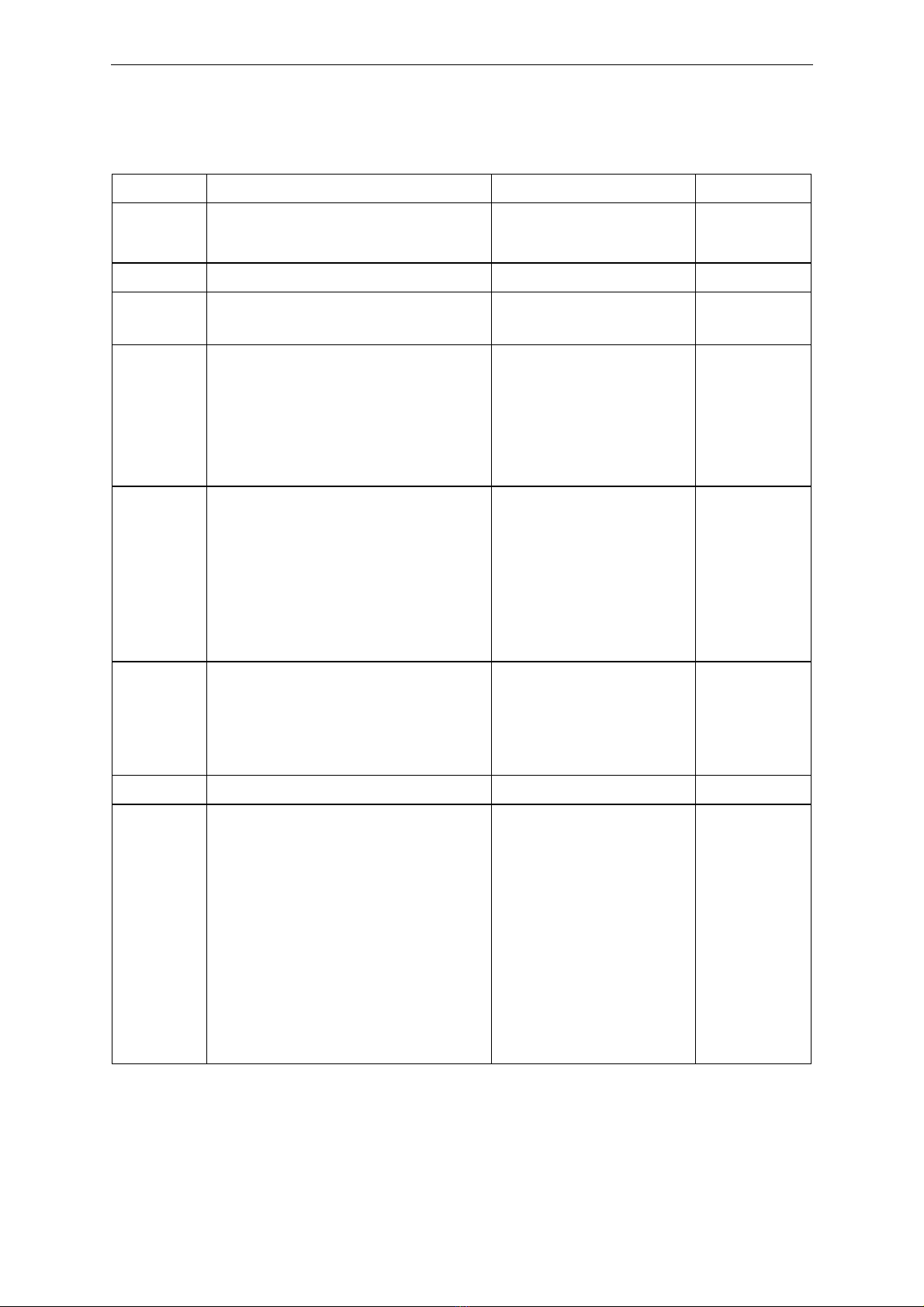

2. MAINTENANCE

7

2-2 Engine Oil

CHANGE THE OIL

Draining can be performed rapidly and

completely while the gasoline engine is

still warm.

1) Remove the oil dipstick and drain

plug to drain the oil.

2) Reinstall the drain plug, and then

tighten the plug securely.

The torque of drain plug: 22±2N.m

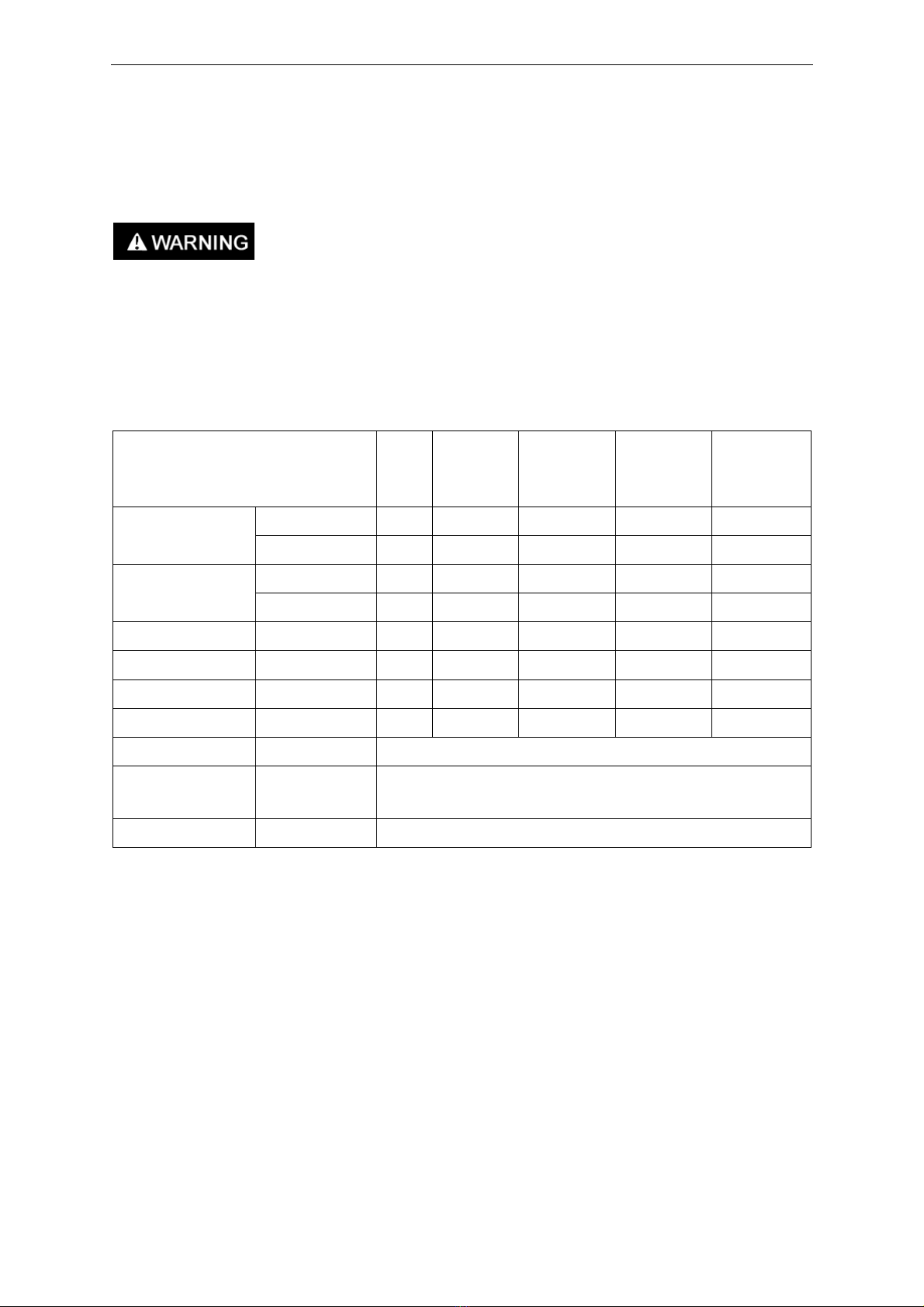

3) Refill oil to the standard ( as shown in the right picture)and check the oil level.

4) Reinstall the oil dipstick.

Using engine oil may cause skin cancer if repeatedly let it contact

with the skin for prolonged periods. Although this is unlikely that

you hardly used oil on a daily basis, it is still advisable to thoroughly wash your hands

with soap and water as soon as possible after handling used oil.

Please dispose of used engine oil in a manner that is compatible with the environment. We

suggest you take it in a sealed container to your local service station or recycling center for

reclamation. Do not throw it in the dust heap or pour it on the ground.

2-3 Air Cleaner Service

A dirty air cleaner will restrict air flow to the carburetor. To prevent carburetor malfunction,

service the air cleaner regularly. Service more frequently when operating the generator in

extremely dusty areas (the period is shown in the 2-1 maintenance list, operating as follow.).

Using gasoline or flammable solvent to clean the filter element can

cause a fire or explosion. Only use soapy water or nonflammable

solvent.

Never run the generator without the air cleaner. Rapid engine wear

DRAIN PLUG

LOWER LEVEL

UPPER LEVEL

OIL DIPSTICK