CONTENTS

°GENERAL INFORMATION ........................................................................................... 6

1-1Main Components ......................................................................................................... 6

1-2General parameter ......................................................................................................... 7

MAINTENANCE ............................................................................................................. 9

2-1Maintenance table ......................................................................................................... 9

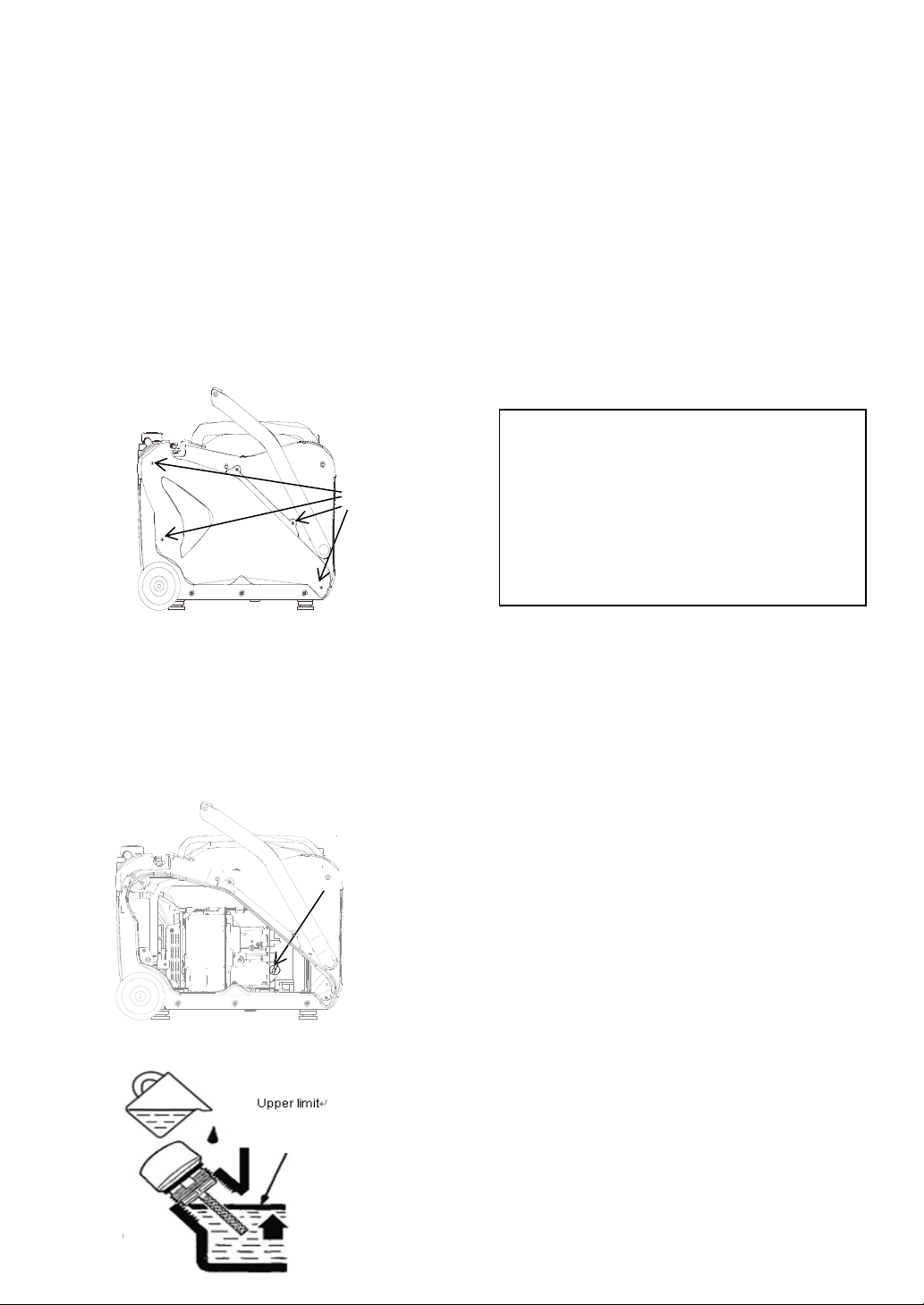

2-2Engine oil .................................................................................................................... 10

2-3Air cleaner .................................................................................................................. 11

2-4Clean fuel strainer ....................................................................................................... 12

2-5Spark arrestor .............................................................................................................. 12

2-6Spark plug ................................................................................................................... 13

2-7 Valve clearance adjustment ..................................................................................... 13

FAILURE PREDICTION AND REPAIR ....................................................................... 16

3-1Failure prediction ........................................................................................................ 16

3-1-1Start difficultly .................................................................................................. 16

3-1-2Power insufficient ............................................................................................. 18

3-1-3Speed unstable .................................................................................................. 19

3-1-4Can't ignite ....................................................................................................... 19

3-1-5Oil overheating ................................................................................................. 20

3-1-6Abnormal sound ............................................................................................... 20

3-1-7No DC output ................................................................................................... 21

3-1-8Generator Stator Winding too hot .................................................................... 21

3-1-9Indicator light judgment ................................................................................... 22

3-2Repair preparation ...................................................................................................... 23

3-2-1Safety factors .................................................................................................... 23

3-2-2Special tools ..................................................................................................... 24

3-3Disassemble diagram .................................................................................................. 25