1

Contents

Part I Introduction ..................................................................................................................................2

1-1 Components of general-gasoline engine ....................................................................................... 2

1-2 Parameters...................................................................................................................................3

1-3 Maintenance limit ..................................................................................................................... 3

Part II Dimension and Torque....................................................................................................................5

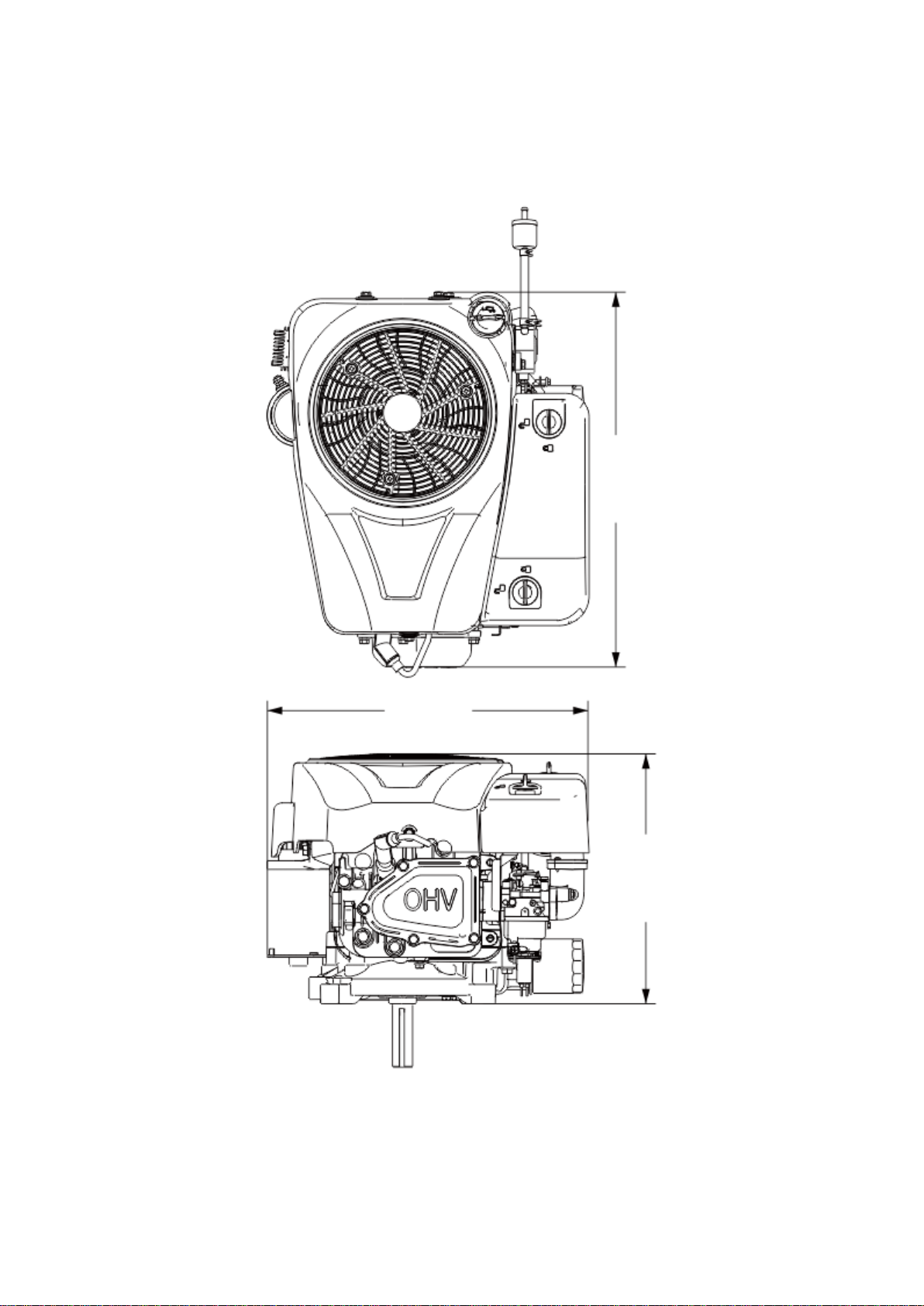

2-1 Dimensions of general-purpose gasoline engine ........................................................................... 5

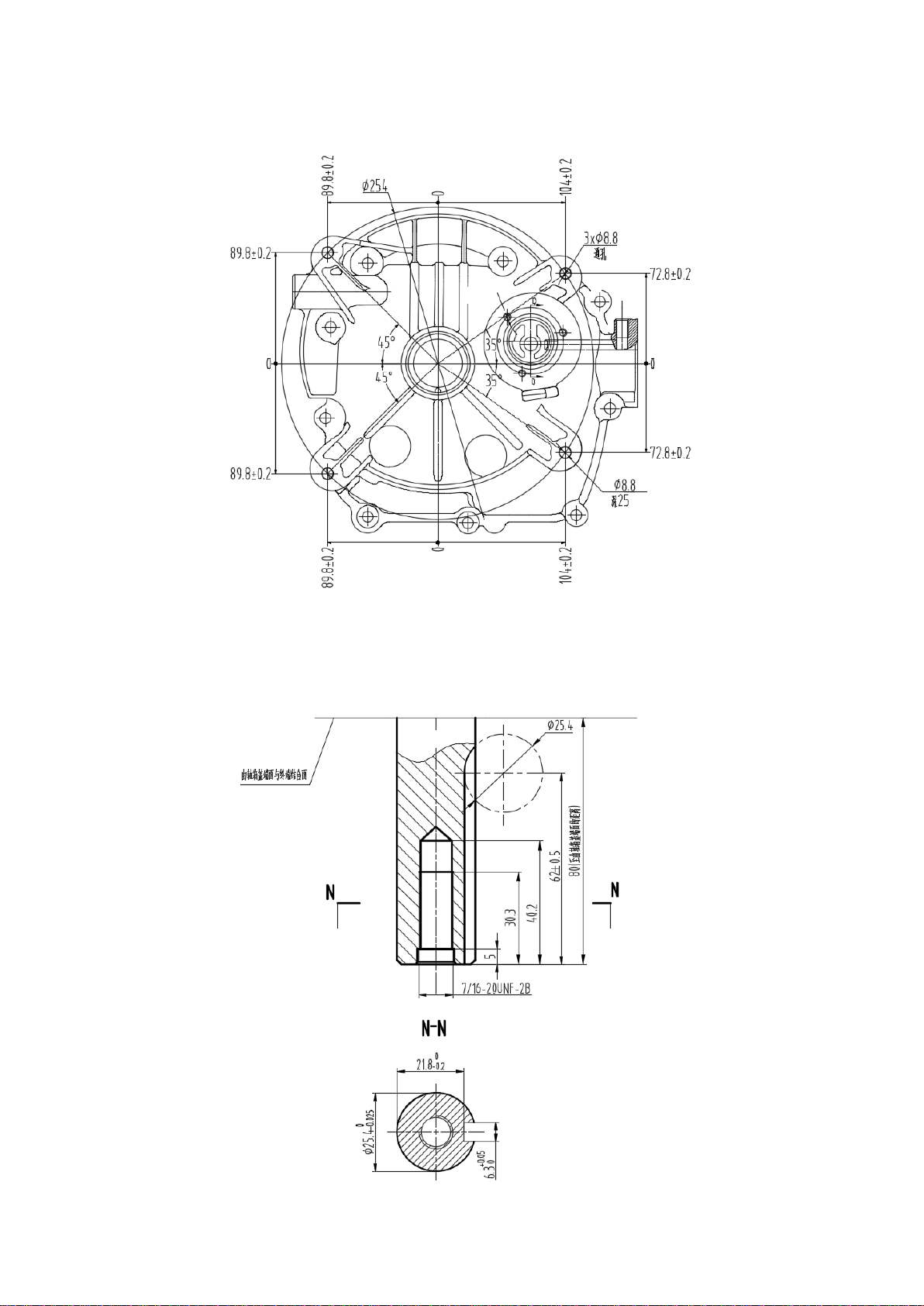

2-2 Locations of mounting holes........................................................................................................6

2-3 PTO installation drawing .............................................................................................................6

2-4 Torque parameters .......................................................................................................................7

2-5 Standard torque parameters..........................................................................................................7

Part III Maintenance...............................................................................................................................8

3-1 Maintenance list...........................................................................................................................8

3-2 Oil...............................................................................................................................................9

3-3 Air filter..................................................................................................................................... 10

3-4 Spark plug ................................................................................................................................. 11

3-5 Adjustment of valve clearance.................................................................................................... 13

3-6 Governor ................................................................................................................................... 14

Part IV Disassembly and Maintenance..................................................................................................... 15

4-1 Troubleshooting......................................................................................................................... 15

4-1-1 Start difficulty................................................................................................................. 15

4-1-2 Underpowered................................................................................................................. 16

4-1-3 Unstable speed................................................................................................................ 17

4-1-4 Unable to Ignite .............................................................................................................. 18

4-1-5 Overheating of general-purpose gasoline engine.............................................................. 18

4-1-6 Abnormal sound.............................................................................................................. 19

4-2 Pre-maintenance Preparations .................................................................................................... 19

4-2-1 Safety factors.................................................................................................................. 19

4-2-2 Special tools.................................................................................................................... 21

4-3 Disassembly chart...................................................................................................................... 22

4-4 general-purpose gasoline engine................................................................................................. 22

4-4-1 Muffler ........................................................................................................................... 22

4-4-2 Air filter.......................................................................................................................... 23

4-4-4 Carburetor....................................................................................................................... 26

4-4-5 Flywheel......................................................................................................................... 30

4-4-6 Ignition coil detection...................................................................................................... 31

4-4-7 Charging coil detection ................................................................................................... 32

4-4-8 Voltage regulating rectifier.............................................................................................. 33

4-4-9 Cylinder head/valve ........................................................................................................ 34

4-4-10 Crankshaft/Piston.......................................................................................................... 40

4-5 Electrical schematic diagram...................................................................................................... 48