1

016-0159-572

9/97 TABLE OF CONTENTS

SYMBOL DEFINITION ............................................................................................................................................. 2

INTRODUCTION ...................................................................................................................................................... 3

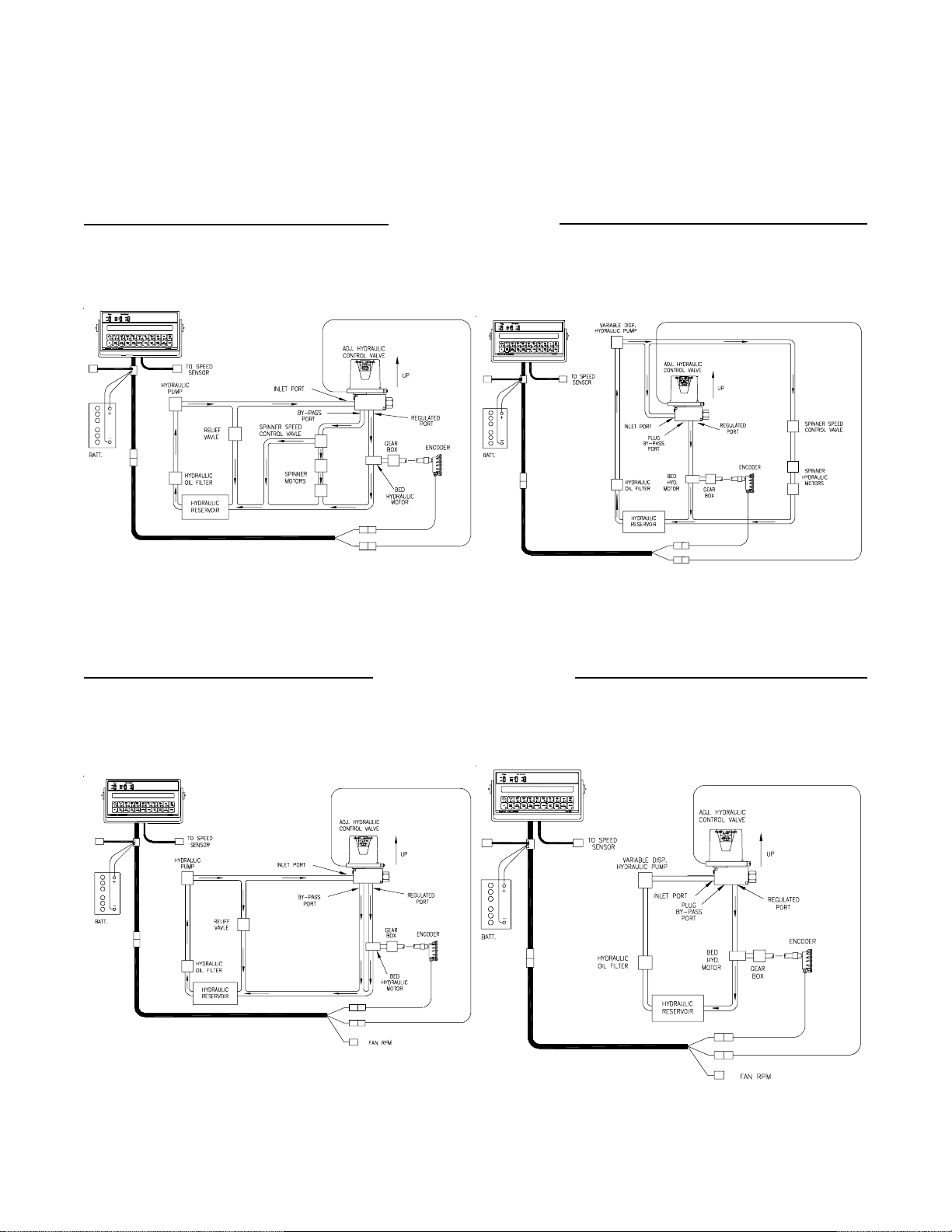

INSTALLATION......................................................................................................................................................... 4

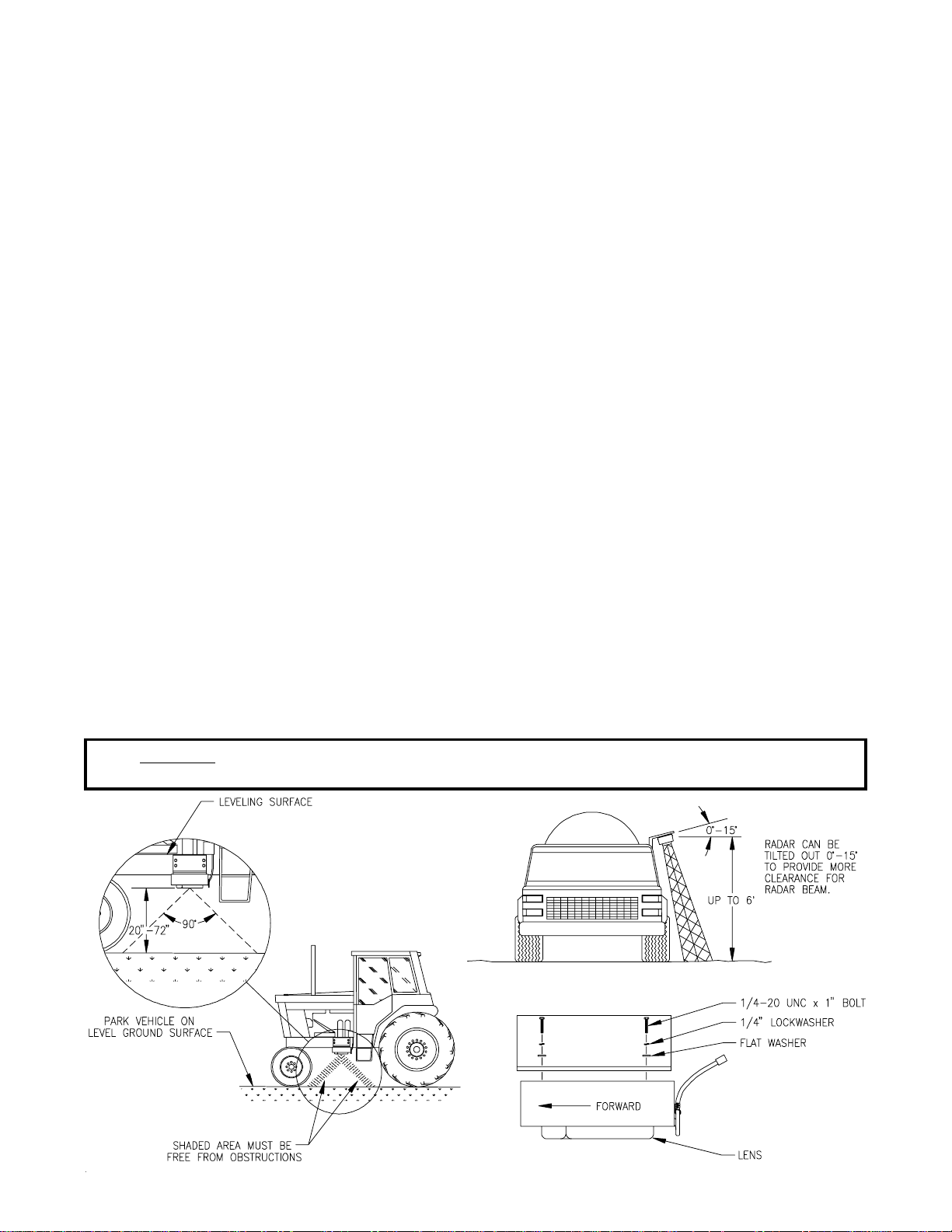

1. MOUNTING THE RAVEN RADAR SPEED SENSOR .................................... 4

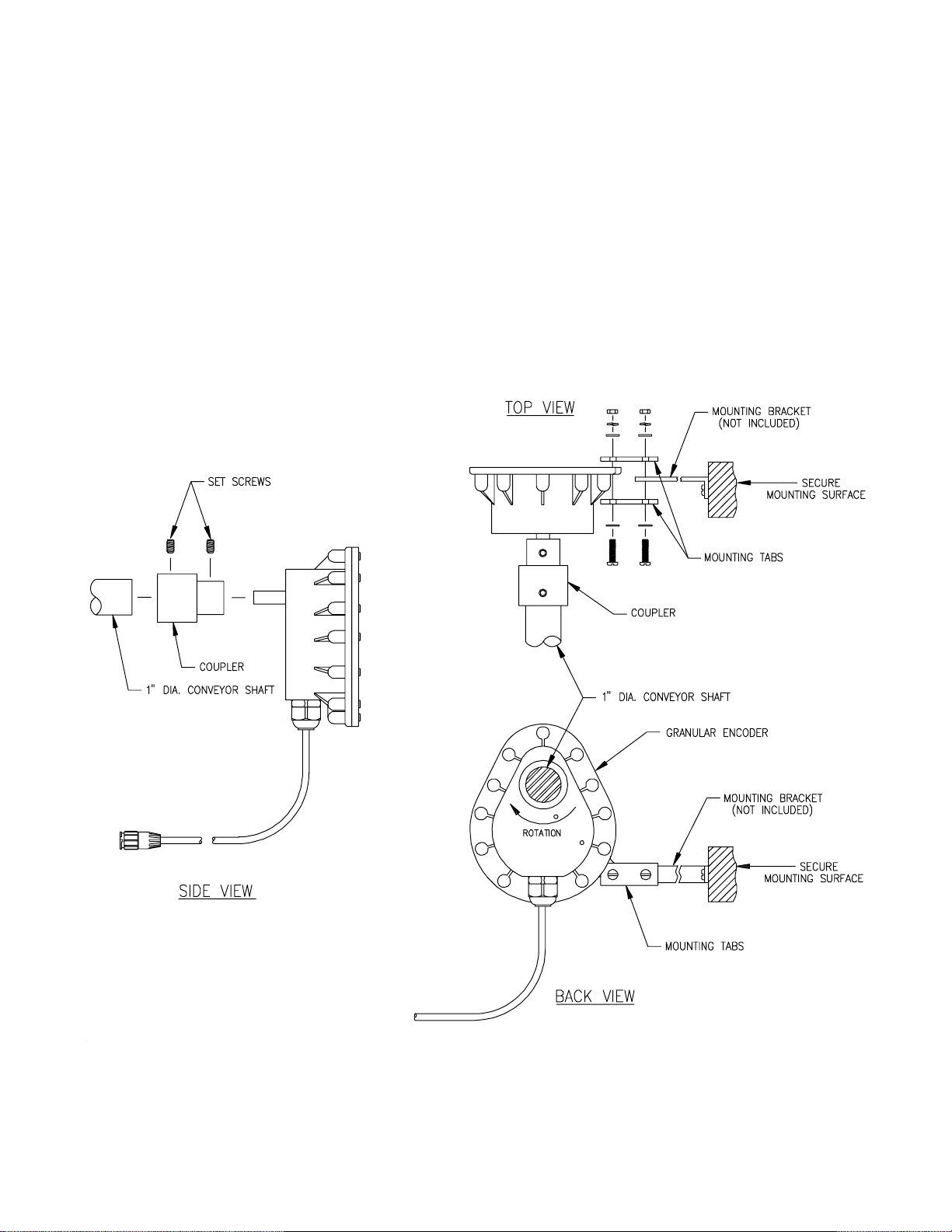

2. MOUNTING THE ENCODER ..................................................... 5

3. MOUNTING THE HYDRAULIC CONTROL VALVE ..................................... 6

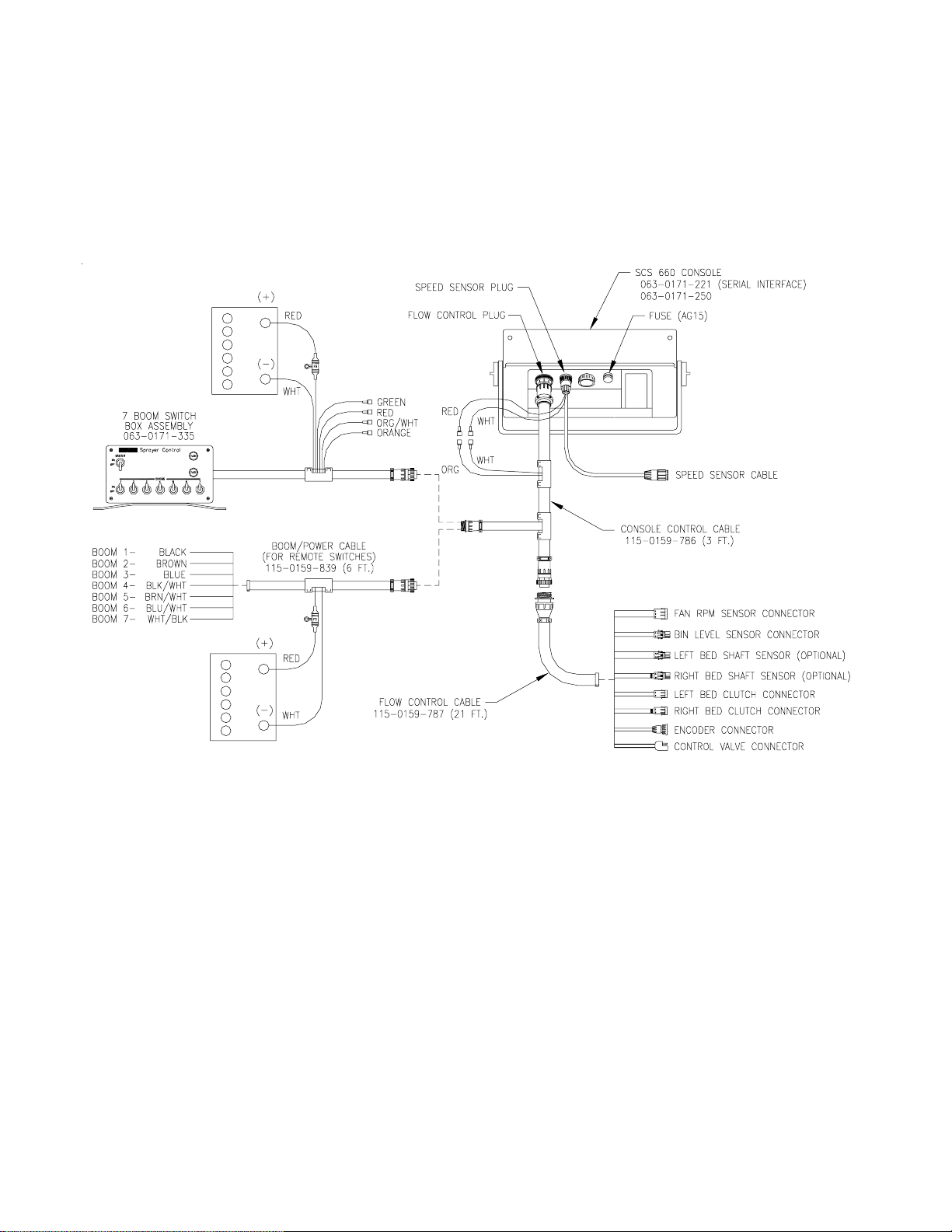

4. MOUNTING THE CONSOLE AND CABLING ......................................... 7

BATTERY CONNECTIONS...................................................................................................................................... 8

CONSOLE FEATURES ............................................................................................................................................ 9

CONSOLE CALIBRATION..................................................................................................................................... 10

1. CALCULATING "BOOM CAL" .................................................. 10

2. CALCULATING "SPEED CAL" ................................................. 10

3. CALCULATING "SPREADER CONSTANT" ......................................... 11

4. CALCULATING "METER CAL" ................................................. 11

5. CALCULATING "VALVE CAL" ................................................. 12

6. CALCULATING "RATE CAL" .................................................. 12

CONSOLE PROGRAMMING ................................................................................................................................. 13

1. INITIAL CONSOLE PROGRAMMING ............................................. 14

2. OTHER DISPLAY FEATURES .................................................. 19

3. SELF TEST FEATURE ....................................................... 20

4. VOLUME/MINUTE RATE FAULT ................................................ 20

5. VOLUME/AREA RATE ALARM .................................................. 20

6. LOW TANK FAULT ........................................................... 20

7. AUTOMATIC RATE +/- ...................................................... 21

8. CONTROL VALVE DELAY ..................................................... 21

9. SEQUENCE TO ACTIVATE DATA-LOCK .......................................... 21

10. SEQUENCE TO CHANGE DATA-LOCK ........................................... 21

11. ENTER MODE SEQUENCE WITH ACTIVATED DATA-LOCK .......................... 22

12. DATA MENU ............................................................... 22

13. DECIMAL SHIFT ........................................................... 29

INITIAL SYSTEM SET-UP...................................................................................................................................... 30

INITIAL SYSTEM FIELD TEST .............................................................................................................................. 30

TROUBLESHOOTING GUIDE............................................................................................................................... 31

APPENDIXES

1. PROCEDURE TO TEST SPEED SENSOR EXTENSION CABLES ............................................................... 33

2. PROCEDURE TO TEST ENCODER CABLES................................................................................................. 34

3. FAN RPM SENSOR INSTALLATION................................................................................................................ 35

4. BIN LEVEL SENSOR INSTALLATION.............................................................................................................. 36

5. SERIAL INTERFACE.......................................................................................................................................... 37

6. SCS 660 COMMUNICATION STRINGS........................................................................................................... 38

7. VERIFICATION OF SPREADER CONSTANT ................................................................................................. 39

8. WHEEL DRIVE SPEED SENSOR INSTALLATION ......................................................................................... 40

9. SPEEDOMETER DRIVE SPEED SENSOR INSTALLATION.......................................................................... 43

REPLACEMENT PARTS SHEETS