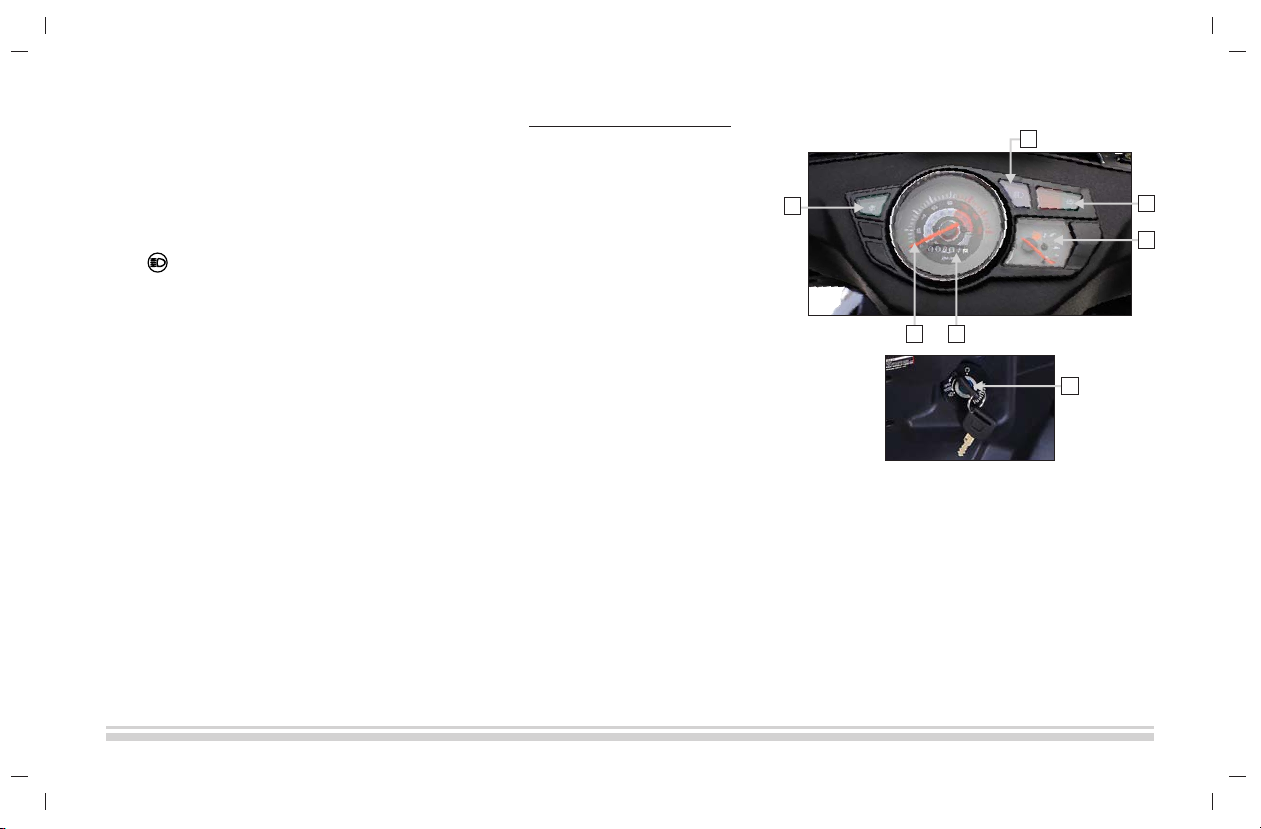

Right handlebar control switches

1. Headlamp switch –

(a) “ “ position – The headlamp , front parking light and tail lamp are turned ON.

(b) “ “ position – All lamps are turned OFF.

(c) “ “ position – Front parking lamp and tail lamp are turned ON.

2. Electric starter switch – When this switch is pressed, starter motor cranks the engine. This

switch should not be pressed over 5 seconds continuously.

Seat

To open the seat insert the ignition key into seat lock and rotate. Then hold the seat and lift it up.

To lock the seat put it down and press downwards.

Fuel tank & Fuel tank cap

The capacity of the fuel tank is 5.5L.

(a) Position of the fuel tank – Fuel tank is mounted beneath the seat.

(b) Opening fuel tank cap –First you need to open the seat, then rotate the fuel tank cap

in anti-clockwise direction.

(c) Closing fuel tank cap - To close fuel tank cap, place the cap on fuel filling neck of fuel

tank and rotate it in clockwise direction.

1

2

(7)