tion is reached release the "Fast Forwardt'knob and

set the machine for normal playback.

To Edit And Splice Tape:

NOTE: It is impossible to edit and splice one track

of a tape without affecting the other track.

Therefore any recordings to be edited should

be limited to one track only.

l. The tape may be edi.ted by cutting out unvanted

sections, joining selections in another sequence, in-

serting announcements, etc. Unused sections can be

spliced together for reuse.

2. Forbest results, cut tapeat a slightdiagonal,

join ends together with splicing tape and cut off any

excessive width.

CAUTION: Do not use ordinary cellulose tape because

it will bleed through causing the tape to

stick together.

Erasing Recorded Material:

1. When a recording is being made the tape is

automatically erased on the track that is being re-

corded. The second half of the tape is not affected.

2. To erase a recording without recording new

material on the tape, proceed to record as normally

except turn the volume control completely down.

ADJUSTMENTS

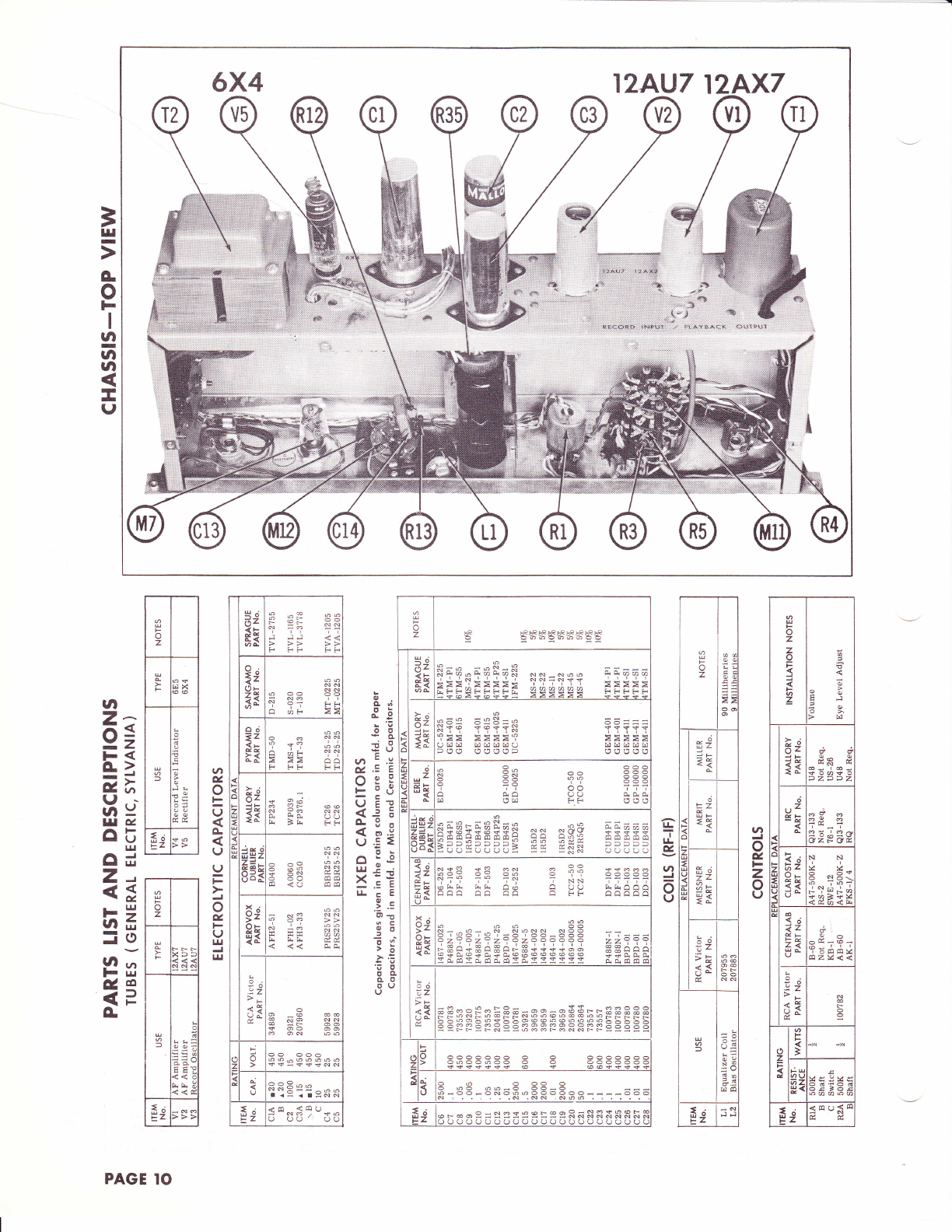

Record/ Playback Head Adjustment:

The record-playback head is mounted to the

front panel by two scre\ps in a hinge arrangement.

Adjust as follows:

1. Thread an alignment tape into the unit as de-

scribed under "Threading The Taperr.

2. Connect an audio voltmeter or oscilloscope

to the output of the playback amplifier.

3. Playback a section of the alignment tape and

adjust the volume control until a convenient reading

ig obtained.

4. Again start the tape over the heads. While

observing the output reading adjust the left-hand head

mounting screw for maximum reading. When the

mildmum has been reached the head is properly

aligned.

NOTE: It is advisable to first loosen the left hand

screwto mal<e sure that when adjustingit will

pass through the maximum reading. Final

adjustment should leave the screw set for

maximum reading.

Hum Adjustment:

The record-playback head shield is adjusted to

reduce hum as follows:

l. Rockingthe head shieldwill produce anotice-

able variation in hum level.

2. Adjust the shield to the position which gives

PAGE 4

the lowest hum level, with the volume control set at

maximum, the unit stopped, no tape on the head, and

set in the "Playback[ position.

3. Realign the head alter the hum adjustment.

CAUTION: Neverlet the head cover drop on the head.

This not only affects the hum adjustment,

but also the head alignment.

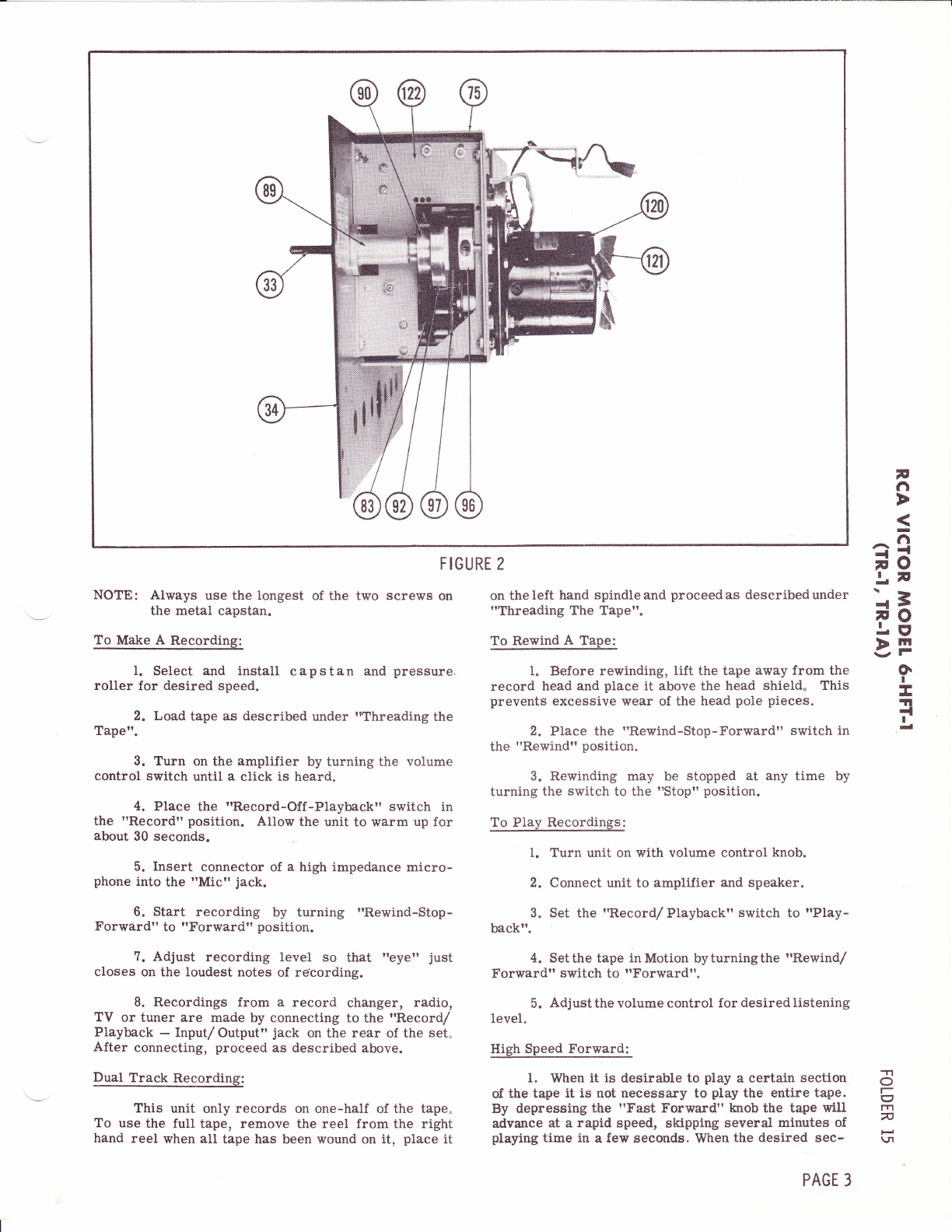

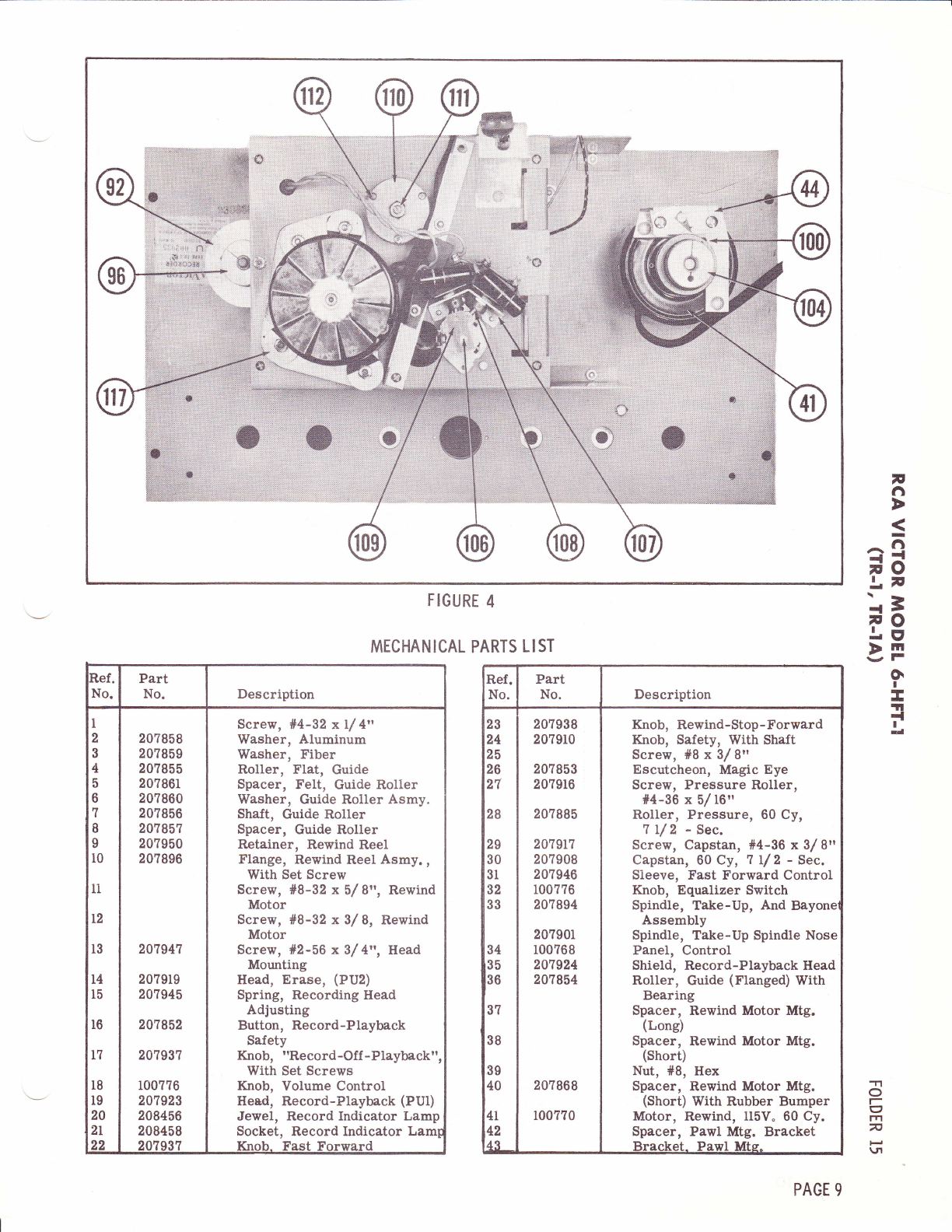

Rewind And Take:Up Drag Adjustment:

Adjustments to the friction drag system are

measured by means of a 0 to I pound spring scale

fastened to string wound several times around the hub

of a ?" reel. Place the reel on the spindle to be ad-

justed and pull on the scale slowly until the reel re-

volves. Note the reading. The rewind drag should

be set at 3 to 4 ounces and the take-up drag at 6 to ?

ounces.

Adjustment is made by loosening the socket

head set screw in split nut (96) or (104) rotating the

split nut and tightening the set screw again before

measuring. Knurled nut (I04) adjusts rewind drag

and nut (96) adjusts take-up drag.

CLEAN ING

The head assemblies, pressure roller, and

capstan are subject to an accumulation of tape coating

residue, which is worn off the tape as it passes these

parts. Use a soft cloth dipped in carbon tetrachloride

to clean these parts, being careful not to saturate the

pressure roller and heads. Saturation of these parts

with carbon tetrachloride can canse damage to the

tape and oilite bearings.

CAUTION: Donot use a brushwhencleaning theheads

ae this could possibly mar the pole

surfaces.

LUBRICATION

Most bearings in this unit are of the porous

bronze (oitite) type that retain oil over long periods

of time. The bearings are kept damp by felt wick.

pads. Oil should be applied to the wicks, and not the

shafts or bearings. Use a good quality SAE #30 oil"

Motors:

Two or three drops on front and back bearings

every 6ix months.

Capstan ShaJt Bearings:

Two or three drops on felt pads every six

months.

Intermediate Idler Wheels:

One drop of oil on felt washers every six

months.

Take-Up Clutch And Rewind Brake:

Do not oil unless squeaking, then one or two

drops of oil on felt pads.