II

Table of contents

1ABOUT THIS MANUAL.........................................................................................................................................1

1.1 Validity, purpose and scope of this document and legal regulations.........................................................................1

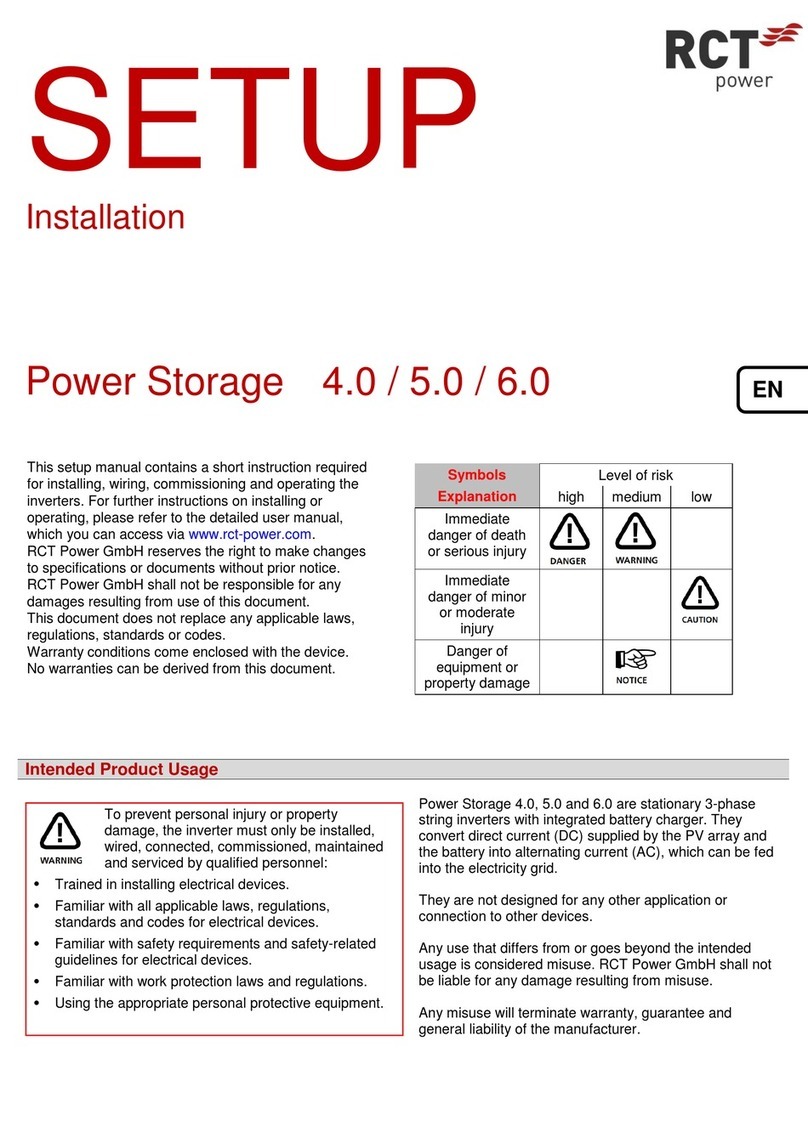

1.2 Explanation of Symbols and References.....................................................................................................................1

2SAFETY INSTRUCTIONS........................................................................................................................................2

2.1 Personnel and Qualifications......................................................................................................................................2

2.2 Safety Procedures.......................................................................................................................................................3

3PRODUCT PRESENTATION ...................................................................................................................................4

3.1 Intended use...............................................................................................................................................................4

3.2 Product specification ..................................................................................................................................................5

3.2.1 Scope of supply...........................................................................................................................................................5

3.2.2 Component description..............................................................................................................................................5

3.2.3 Type plate and warning signs .....................................................................................................................................7

4MECHANICAL INSTALLATION...............................................................................................................................8

4.1 Select mounting location............................................................................................................................................8

4.2 Mounting ..................................................................................................................................................................10

5ELECTRICAL INSTALLATION................................................................................................................................11

5.1 Connections overview ..............................................................................................................................................11

5.2 AC connection...........................................................................................................................................................11

5.3 Configuration of the PV inputs .................................................................................................................................12

5.4 DC connection ..........................................................................................................................................................13

5.4.1 DC connector assembly ............................................................................................................................................14

5.4.2 DC Battery connection..............................................................................................................................................16

5.5 Disconnecting voltage sources .................................................................................................................................17

5.6 Additional Protective Conductor Connection...........................................................................................................18

5.7 Connection –Power Switch......................................................................................................................................18

5.8 Connection –Power Sensor......................................................................................................................................20

6COMMUNICATION PORTS.................................................................................................................................21

6.1 I/O circuit board .......................................................................................................................................................21

6.1.1 RS485 - X102 Interface .............................................................................................................................................22

6.1.2 Multifunction relay X100 Interface...........................................................................................................................22

6.1.3 Ripple control signals X101 Interface .......................................................................................................................23

6.1.4 Digital Inputs and Outputs X103 Interface ...............................................................................................................23

6.2 Connection Ethernet Interface.................................................................................................................................24

6.3 RJ45 connections for Power Battery, Power Sensor and Power Switch...................................................................25

6.3.1 Wiring the RJ45 interfaces........................................................................................................................................25

7COMMISSIONING..............................................................................................................................................26

7.1 Commissioning .........................................................................................................................................................26

7.1.1 Switch on the Inverter ..............................................................................................................................................26

7.1.2 Accessing the inverter ..............................................................................................................................................27

7.1.3 Configuring the Inverter ...........................................................................................................................................28

7.1.4 Setting Solar plant peak power and External power reduction................................................................................29

7.1.5 Configuring the Battery ............................................................................................................................................30

7.1.6 Configuring the Power Sensor (during operation) ...................................................................................................31

7.1.7 Expert Settings Battery.............................................................................................................................................32

7.1.8 Connecting the inverter to a network via a Wi-Fi connection..................................................................................34

7.1.9 Connecting the inverter to a network via an Ethernet connection..........................................................................37