4

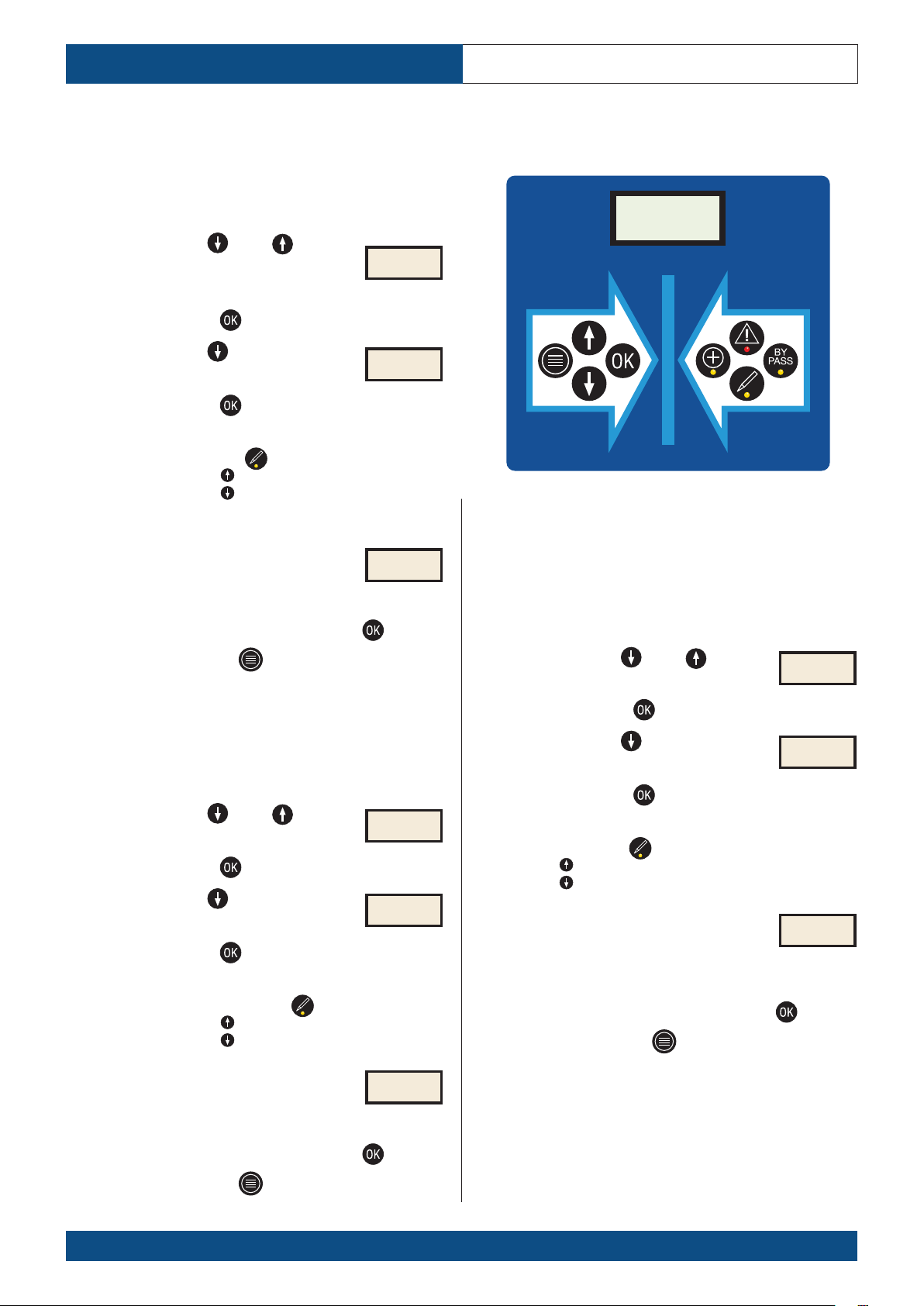

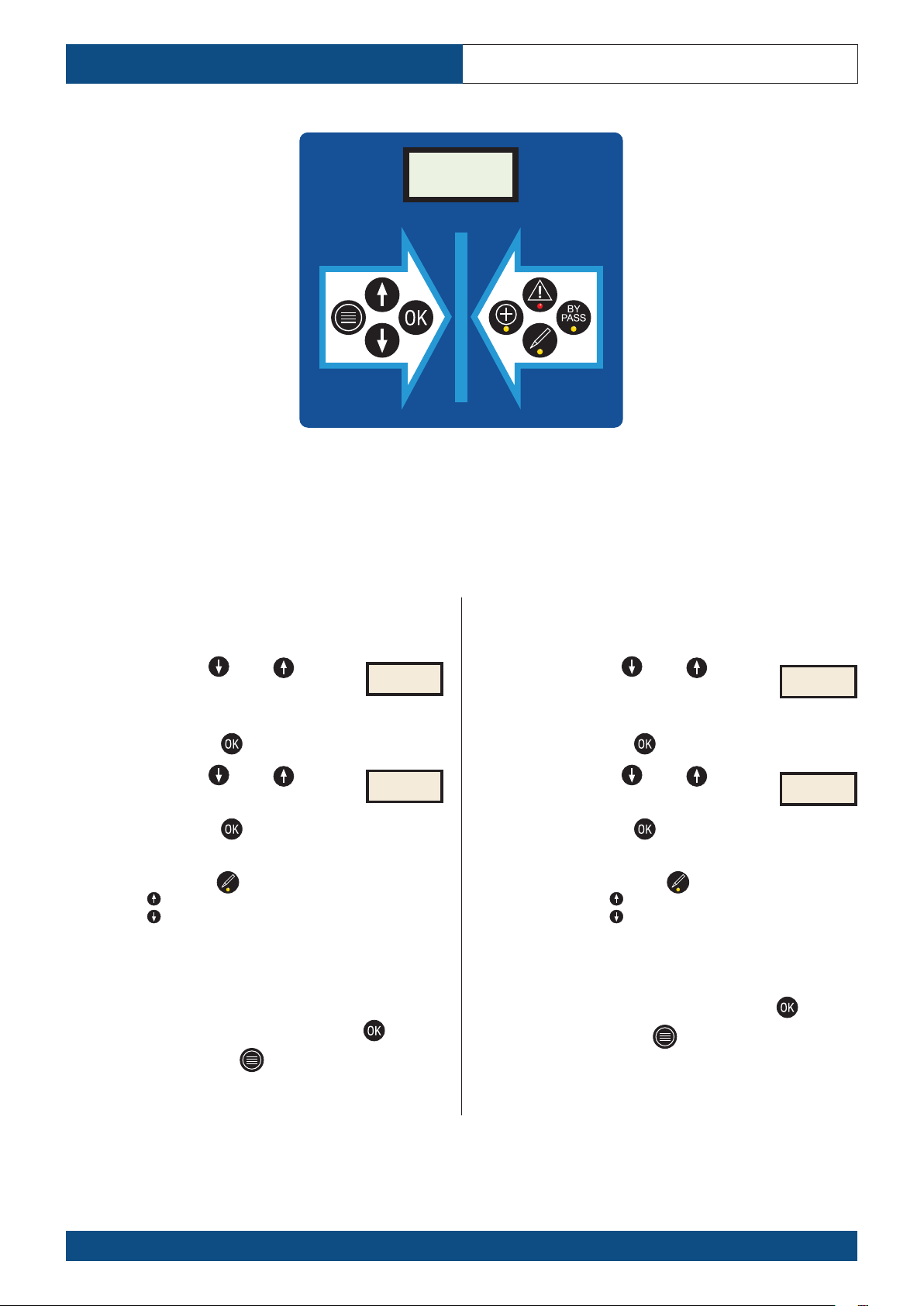

Frånluft Avluft

Uteluft

Tilluft

REC Indovent AB, Box 37, SE-431 21 Mölndal, Sweden | tel. +46 31 675500 | www.rec-indovent.se

OPERATION & MAINTENANCE Air handling unit RT 400S-EC

REC-E08.10

General/Introduction

REC Indovent has been manufacturing Temovex air

handling units since the 1970s.

User-friendliness has been the order of the day right from

the outset. For us, one of the most important things is

to make sure our users feel secure and can handle the

minimum of maintenance with no fuss. And of course, the

fact that you also demand market-leading performance

as regards energy consumption and recovery is also a

natural consideration in our ongoing development work.

Our amassed experience has all been combined to

create your Temovex unit.

Temovex units are a quality product made in Sweden,

with a long service life and extreme reliability with no

unpleasant surprises.

And just to prove that our efforts are taking us in the

right direction, Temovex units have won first prize in

the Swedish Energy Agency’s technology development

competition, looking for the best ventilation heat

exchanger. The motto for the competition was as follows:

“To save energy and the environment with inexpensive,

efficient, reliable ventilation heat exchangers”.

To ensure your entire ventilation system maintains its

performance throughout its entire design service life, you

should follow the simple maintenance instructions in this

booklet.

This unit is designed for continuous operation. It should

only be shut down for servicing or inspection.

The unit must never be operated with no

filters fitted.

System descriptions

Operation principle

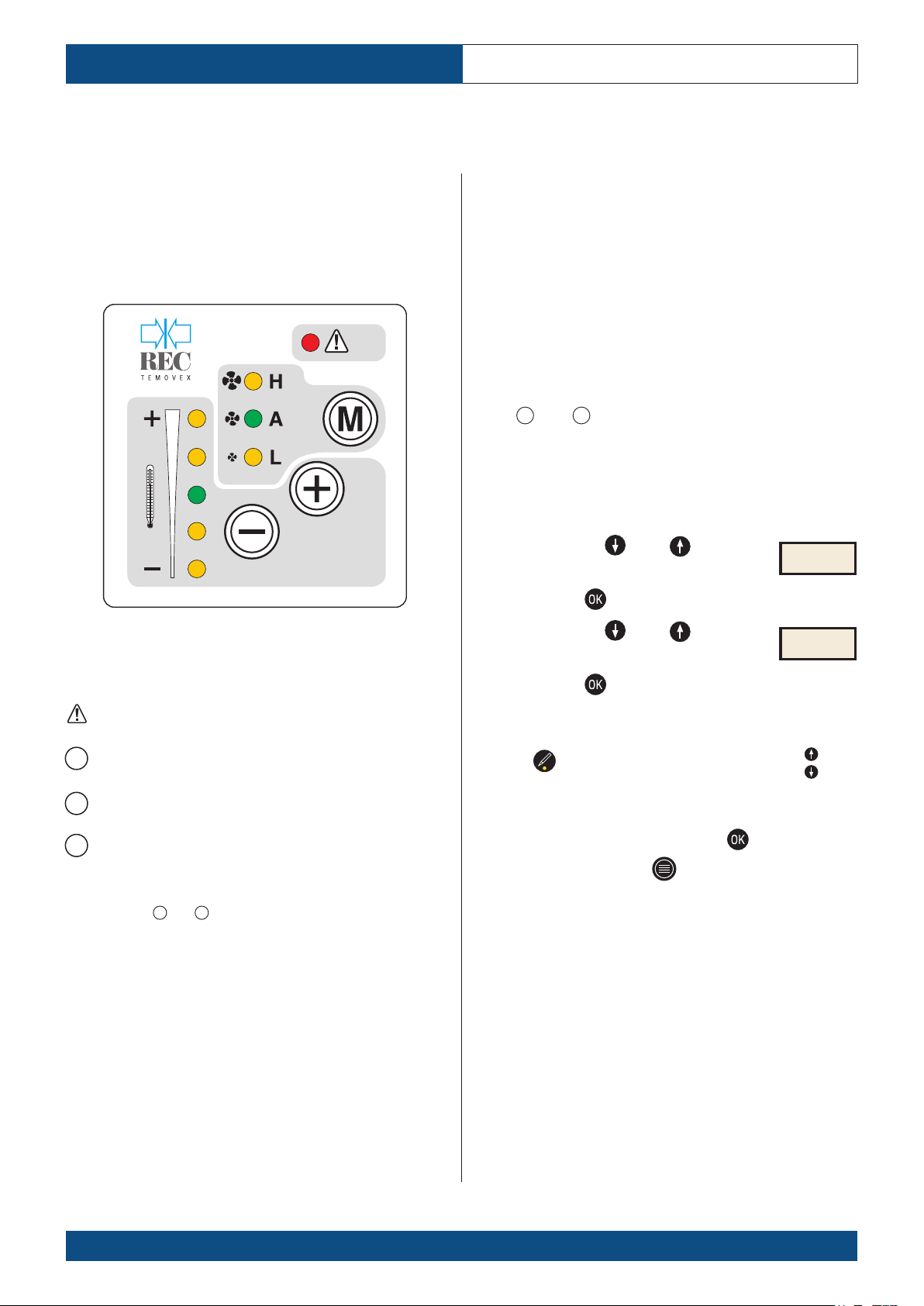

The Temovex unit

The Temovex unit

consists of fans, air filters,

afterheaters and a highly

efficient counterflow heat ex-

changer developed by our-

selves. The counterflow heat

exchanger is very well sealed,

which prevents odours, con-

taminants, etc. from coming

back into the home.

A long service life, low

operating costs and a low

maintenance requirement are

ensured thanks to the use of

top quality, reliable compo-

nents and design solutions

involving few moving parts. The thermal energy in the

air sucked out of the building is transferred in the heat

exchanger to the fresh air coming into the building. The

Temovex unit retains the heat or coolness in the building

without supplying new thermal energy. (Compare this

with a thermos.) Making the most of the thermal energy

already present in the building allows the operating

time and/or size of the conventional heating system to

be reduced. Comfort is also enhanced because the air

entering the home is at a temperature nearer to room

temperature than it would have been if the air had been

taken in directly from outdoors. At the same time, the

indoor environment is really enhanced because all the

air entering the building passes through a fresh air filter

(outdoor air filter). One filter also makes maintenance

easy. With Temovex it’s easy to access!