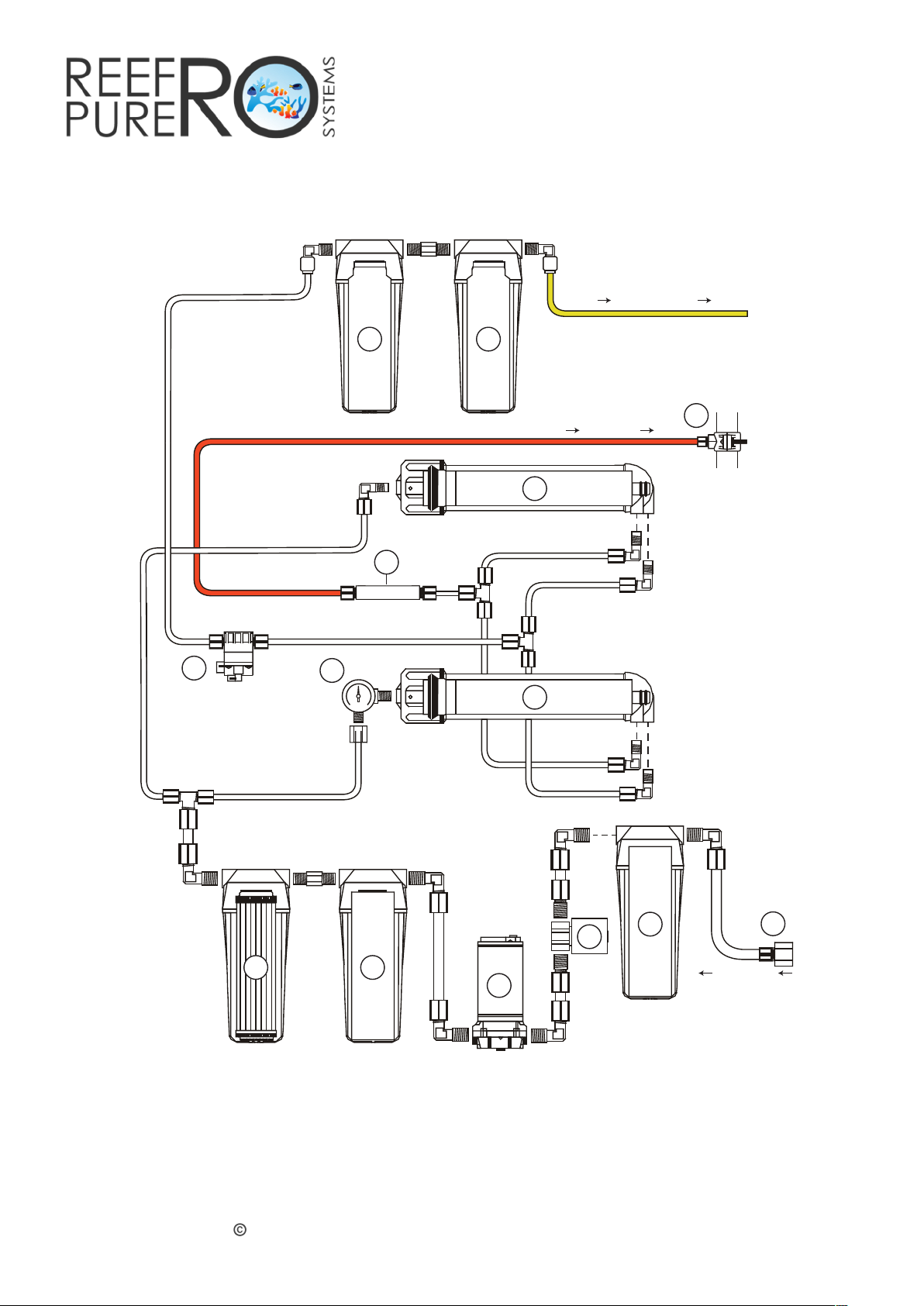

SYSTEM INSTALLATION

1. Start by positioning your RO/DI system in the location it will be utilised in, close to an available water

source and drain connection, making sure to keep it in an indoor location, out of direct sun. Also

position the DI resin stage(s) close by for connection to the system.

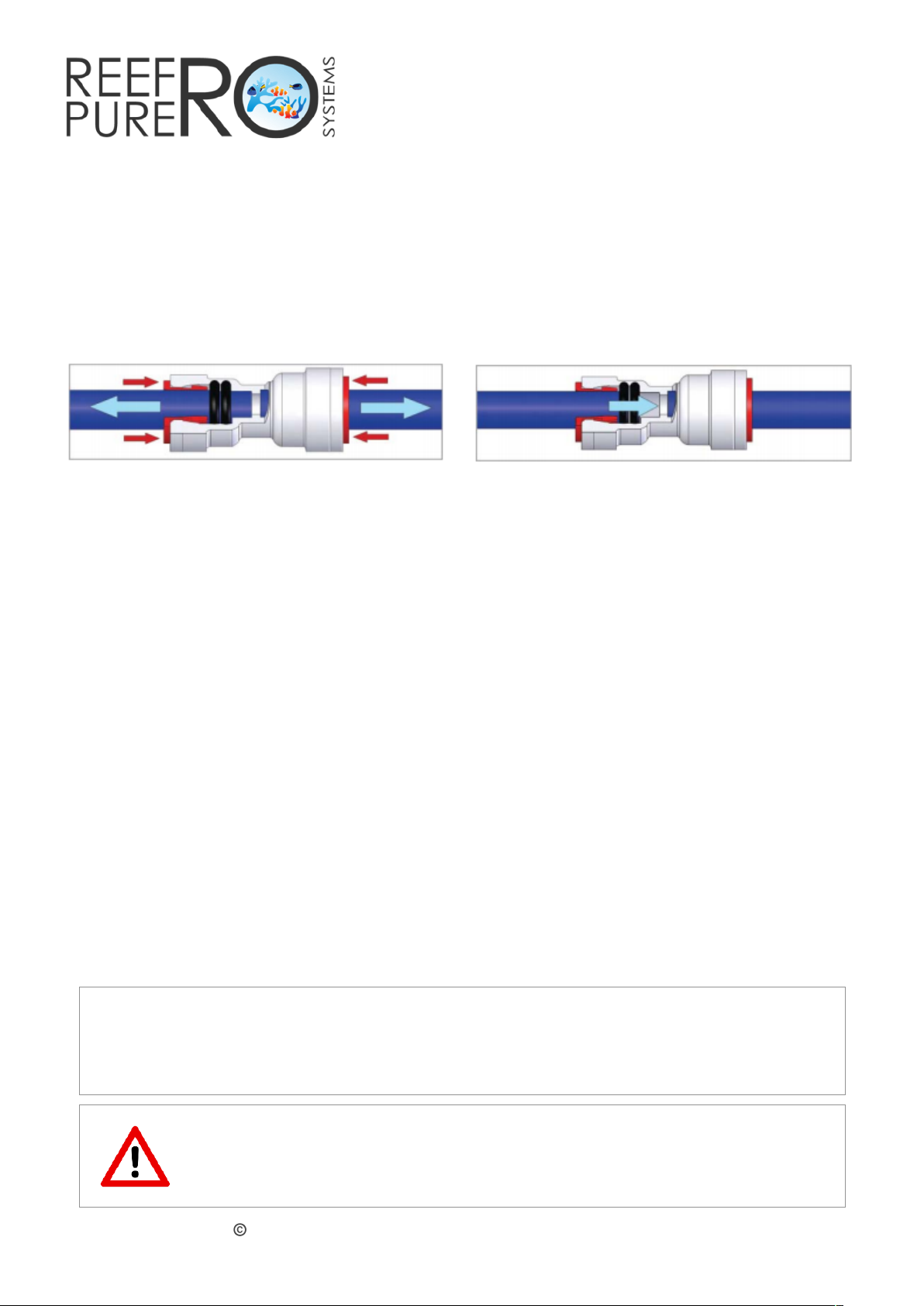

2. The thicker 3/8” white tube is the tap or source water line. Start by connecting one end of it to a tap

water source using the included feed water connector. The other end is then connected to your

systems Sediment filter inlet, located on the front above the sediment filter housing.

3. The red (or black) tube is the wastewater line. Connect one end of it to the 800ml flow restrictor

connector, identifiable by the small piece of red (or black) tube which comes pre-inserted (this is just

for your reference and can be discarded). The water this tube produces contains all of the

contaminants that your system has rejected and should be disposed of. We recommend directing it to

a drain utilising the Wastewater Drain Connector if necessary.

4. The yellow (or blue) tube is the production water line. This will be connected to the RO membrane

housing’s production water lines after the High Pressure Switch, identifiable by the small piece of yellow

tube which comes pre-inserted (this is just for your reference and can be discarded). Measure the tube

required to reach from this connector to the IN (left) side of the DI resin stages. Cut it and connect the

DI resin stage(s) to the main system. With the remaining piece of yellow tube, connect it to OUT

connector from the DI stages (right). This tube can then be directed to your RO/DI water storage

container.

5. Connect the included power adapter to the available power connector on the rear of the system.

Sometimes the connect pins will not immediately align, if this happens wiggle the connector until the

pins align and the power connector clips together.

6. Connect the power cord to the power brick and plug in to an available power outlet.

7. Once all connections have been made, you can turn on the feed in tap. The built in solenoid valve will

prevent the flow of water until power is applied.

8. Switch on power to the system, which will now need to run for 30 minutes with all water produced

discarded in order to flush out any trapped air, preservatives used in manufacturing and fine particles

from carbon filters. This is a good time to check for any leaks and ensure that all connections are