3

TABLE OF CONTENTS

Registration ..................................................................................................................... 2

Table of Contents & Safety Reference Information ......................................................... 3

Tool Quick Reference ....................................................................................................... 4

General Safety Issues ...................................................................................................5-7

SAFETY - System Installation, Pre-Operation and Removal .........................................8-10

Hose Connections and Installation ................................................................................. 8

Pre-Operation of Tool, Disconnecting Hoses .................................................................. 9

SPECIFICATIONS

Hydraulic Fluid ............................................................................................................... 10

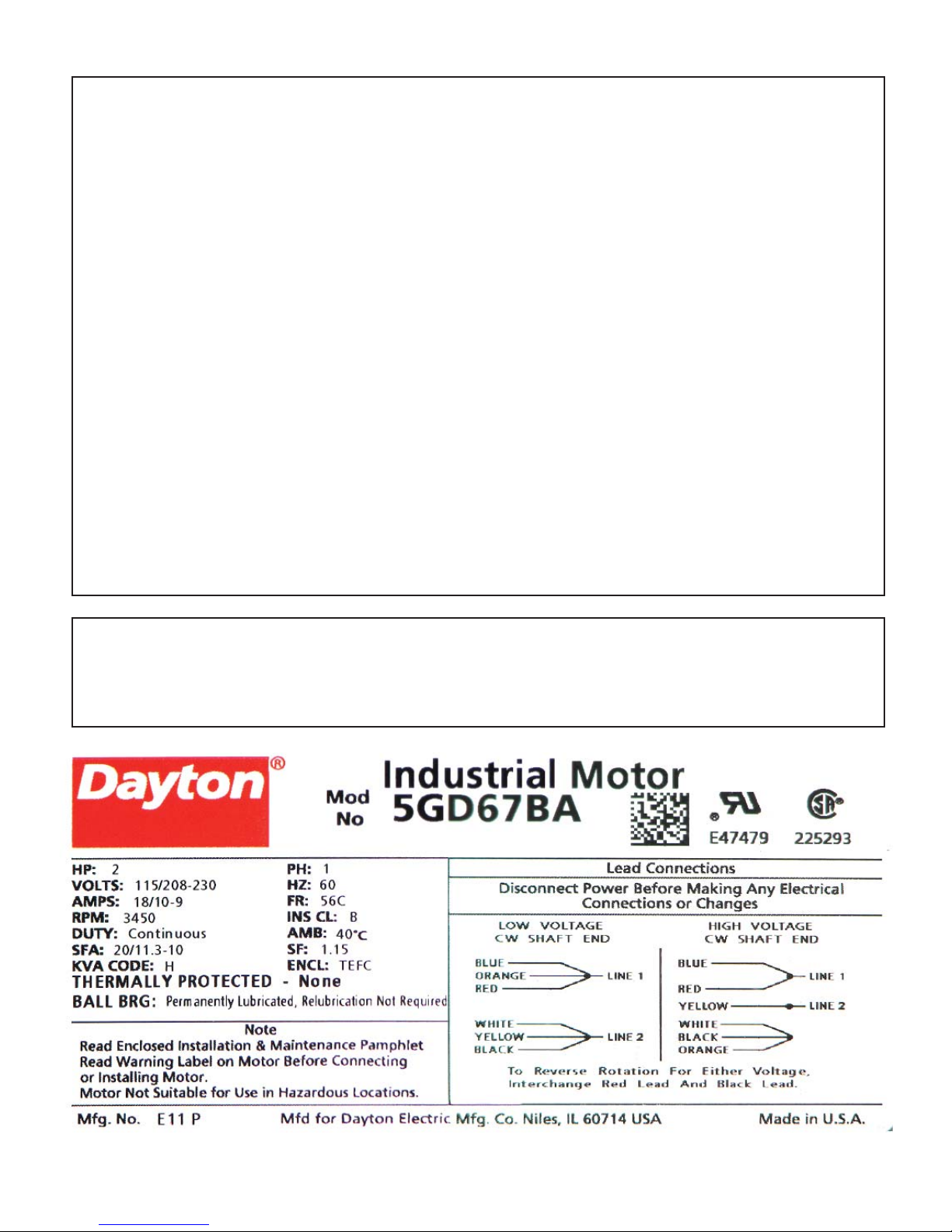

Tool & Motor Specifications ........................................................................................... 10

Visual References .....................................................................................................11-12

Operation (Single Acting) ............................................................................................... 13

Operation (Double Acting) ............................................................................................. 14

MAINTENANCE

Scheduled Maintenance & Label Reference ................................................................. 15

Troubleshooting ........................................................................................................... 16

Before Disassembly, Reservoir Clean & Fill ................................................................. 17

DRAWINGS Major Components (Fig. 1) ................................................................ 18

Inner Pump Assembly (Fig. 2) ........................................................... 19

PARTS LISTS Major Components & Inner Pump ..................................................... 20

Valve Block Assembly ........................................................................ 21

DRAWING Valve Block Assembly (Fig. 3) ............................................................ 22

High Pressure Pump Block (Fig. 4 ), Manifold Outlet Block (Fig. 5) .23

PARTS LISTS High Pressure Pump Block, Manifold Outlet Block

Low Pressure Pump Assembly ........................................................... 24

DRAWING Low Pressure Pump Assembly (Fig. 6) .............................................. 25

Maintenance Record ...................................................................................................... 25

User Notes, Contact Information & Visual Warnings ................................................... 26

THIS SYMBOL INDICATES ITEMS OF EXTREME IMPORTANCE.

Safety of user and others may be in jeopardy if these instructions are not

read and understood.

Operation/Safety methods may vary in accordance with the working

guidelines established by each utility or contractor

For your own safety, ensure that you fully comply with all safe operation

guidelines required by your employer.

WARNING