2. PREPARING FOR USE WITH LIVE STEAM LOCOS.

Channel # 1 is 100% (90°) & Ch # 3 is 150% (135°) servo throw. This will suit most situations.

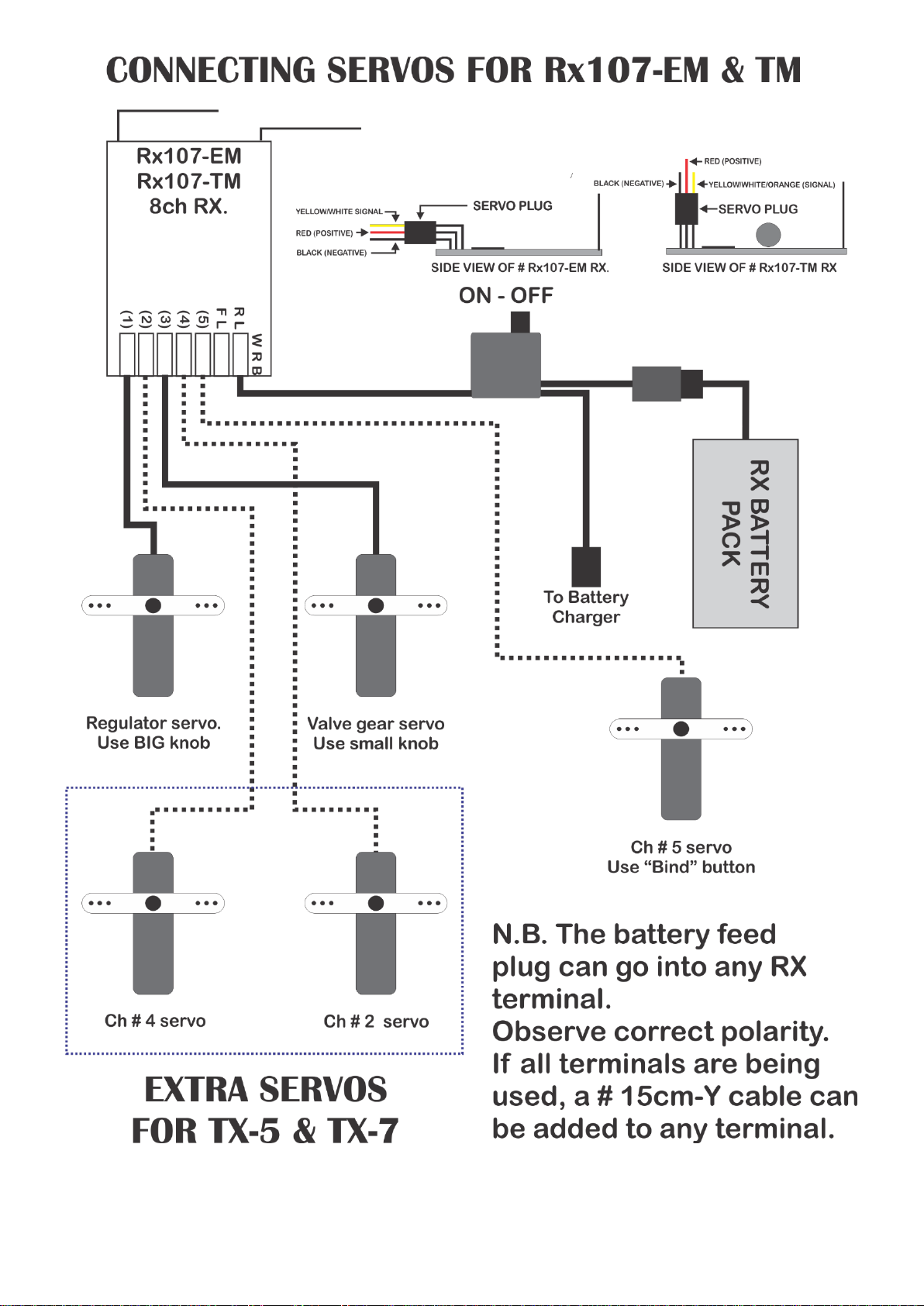

Turn the # EVO-DUPLEX handpiece ON. Make sure Rx is OFF. Then re-insert the servos into the correct Rx sockets.

The Reverser servo goes in Ch # 3 (Elevator) socket. The Regulator servo is controlled by Channel # 1 (Big knob).

N.B. Swapping the knobs will change the servo throws for Regulator & Reverser functions.

However, you can use that feature to increase Regulator servo throw. In this case Ch # 1 becomes the reverser

and Ch # 3 becomes the regulator.

HOW TO ADJUST SERVOS USING Rx107 Auto Bind Rx’s. (See the instructions with our Rx107 receivers).

OR With our # AB-EM & # AB-TM Auto Bind Rx, you can use Plug in, in Line Servo Reversers.

When using for the first time make sure both knobs are centered. Both knobs have a centre détente.

VALVE GEAR REVERSER SERVO.

1.1. Then turn on the Live Steam loco Rx. The two servos should immediately snap to the neutral position.

1.2. Adjust the valve gear servo connecting rod to ensure the centre position of the valve gear matches the servo.

1.3. Turn the reverser knob slowly to the right Clockwise (CW) & check the servo moves the valve gear to the forward

position. If it goes the wrong way you will need to reverse the mechanical connection. See our Rx107 instructions.

If the reverser knob wants to make the servo move too far, put the connecting rod into a servo arm hole closer to the

middle of the servo arm. If it does not move far enough, move the rod into a hole further out.

N.B DO NOT FORCE THE SERVO AGAINST THE STOP. DOING SO WILL DAMAGE THE SERVO.

1.4. Turn the reverser knob slowly and carefully to the left Counter Clockwise (CCW). With regards to any possible

mechanical changes you made during 1.3 above, it should perform correctly.

STEAM REGULATOR SERVO.

2.1. Turn the regulator knob to the left (CCW) the servo will rotate CCW and should close the steam regulator valve.

If it goes the wrong way, you will need to reverse the mechanical connection. See our Rx107 instructions.

If the large knob wants to make the servo move too far, i.e. over closing the regulator, put the connecting rod into a

servo armhole closer to the middle of the servo arm. If it does not move far enough move the rod to a hole further out

OR The Rx107 instructions show how to adjust servo end points on all channels.

N.B DO NOT FORCE THE SERVO AGAINST THE STOP. DOING SO WILL DAMAGE THE SERVO.

2.2. Turn the large knob to the right to check the servo opens the steam regulator far enough.

3. DRIVING LIVE STEAM LOCOS.

Make sure the Tx & Rx are both OFF and the regulator knob is fully CCW. This is the same as the throttle stick on a

conventional stick R/C being fully down.

Ensure the reverser knob is in the middle. Turn ON the # DUPLEX hand piece, & then the loco.

Once steam has been raised, select the direction of valve gear with the CH # 3 Reverser knob. See page # 3.

Then turn the regulator knob CW. That is like raising the throttle stick on a conventional stick R/C.

Turn the big knob CCW to slow the loco. All the way CCW will bring the loco to a stop.

You can have a faster stop by centering the reverser control knob. Then make sure regulator knob is also fully CCW.

The Ch # 5 Bind button.

For Live Steam the Ch # 5 doubles as a whistle control with a servo. It starts at one extreme & when pressed goes fully

the other way. It snaps back to the start point when released. For controlling a servo operated steam whistle.

If not using the # Rx107 receiver you may require a # SIG-REV as default direction is back to front. OR:

For Battery R/C. When the Ch # 5 button is combined with a suitable R/C switch plugged into the Rx, the button can be

used as a sound trigger. For example, the latest MyLocosound features a diesel engine START –STOP feature.

Also suitable for controlling Kadee®servo uncoupler’s.

LOW OFF NEUTRAL LO SET FORWARDS LO SET REVERSE LO SPEED UP