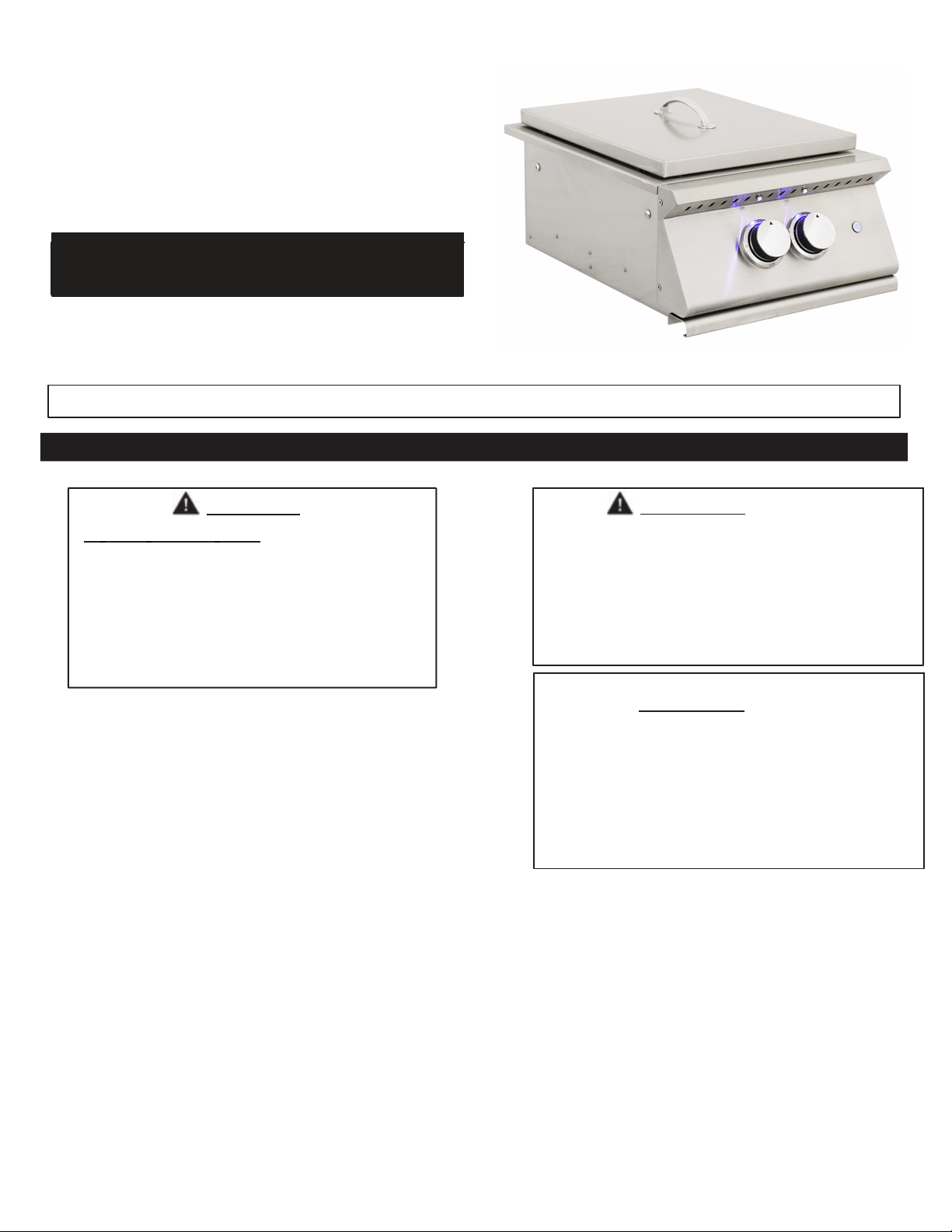

Renaissance

Cooking Systems

PREMIER PROBURNER

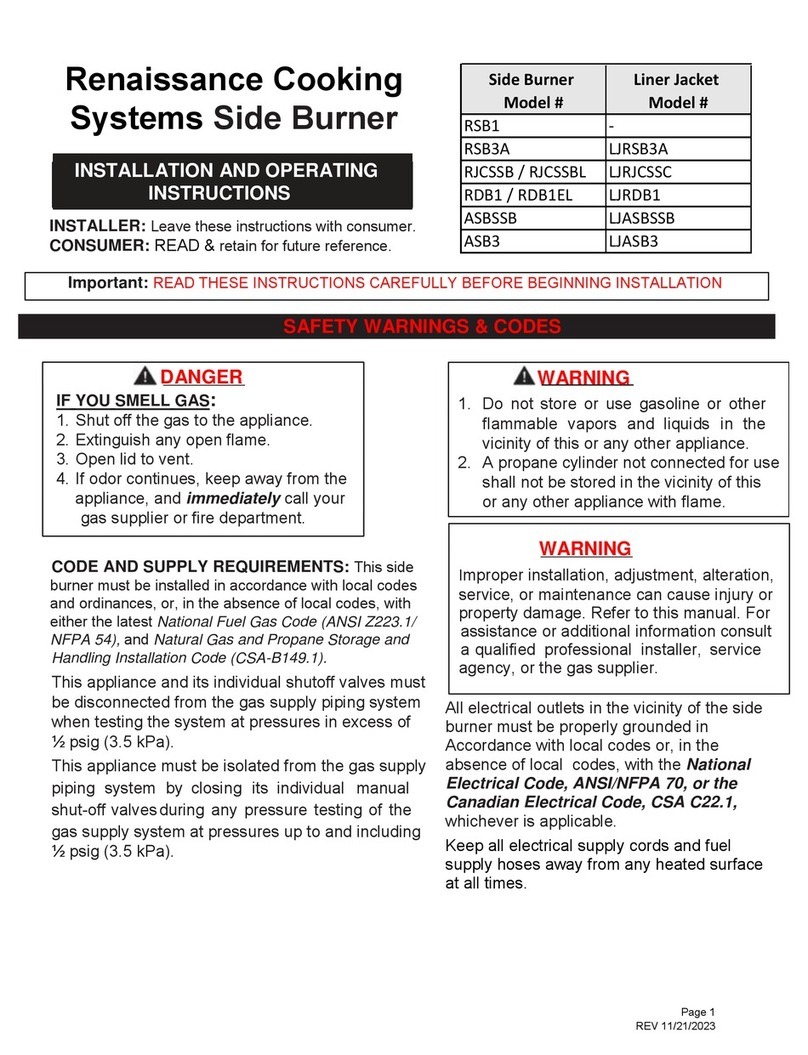

MODEL # RJCSB3A Use Liner Jacket LJRJCSB3A

INSTALLATION AND OPERATING

INSTRUCTIONS

INSTALLER: Leave these instructions with consumer.

CONSUMER: READ & retain for future reference.

Important: READ THESE INSTRUCTIONS CAREFULLY BEFORE BEGINNING INSTALLATION

SAFETY WARNINGS &CODES

DANGER

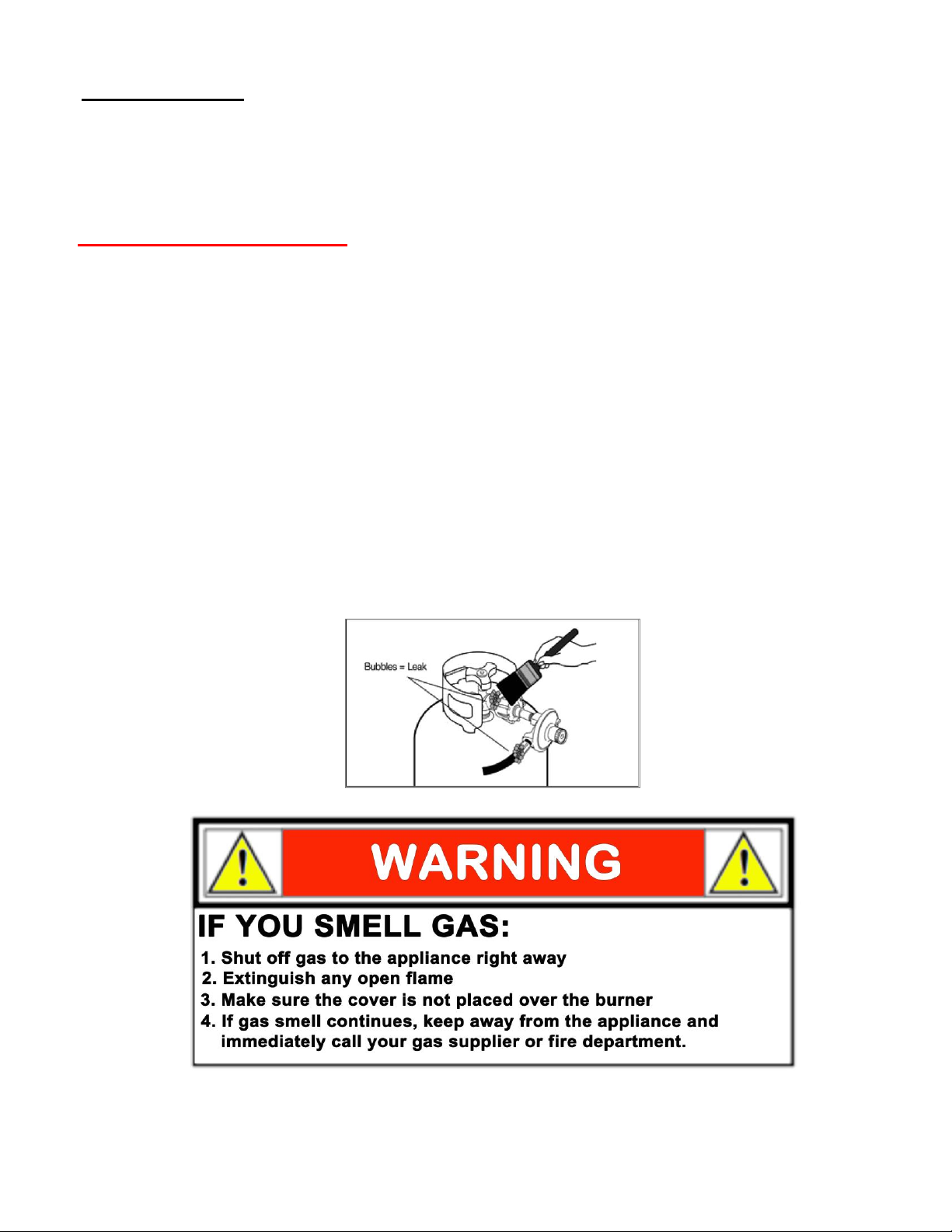

IF YOU SMELL GAS:

1. Shut off the gas to the appliance.

2. Extinguish any open flame.

3. Open lid to vent.

4. If odor continues, keep away from the

appliance, and immediately call your

gas supplier or fire department.

WARNING

1. Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

2. Apropane cylinder not connected for use

shall not be stored in the vicinity of this

or any other appliance with flame.

CODE AND SUPPLY REQUIREMENTS: This pro

burner must be installed in accordance with local codes

and ordinances, or, in the absence of local codes, with

either the latest National Fuel Gas Code (ANSI Z223.1/

NFPA 54), and Natural Gas and Propane Storage and

Handling Installation Code (CSA-B149.1).

This appliance and its individual shutoff valves must

be disconnected from the gas supply piping system

when testing the system at pressures in excess of

½psig (3.5 kPa).

This appliance must be isolated from the gas supply

piping system by closing its individual manual

shut-off valvesduring any pressure testing of the

gas supply system at pressures up to and including

½psig (3.5 kPa).

WARNING

Improper installation, adjustment, alteration,

service, or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult

aqualified professional installer, service

agency, or the gas supplier.

All electrical outlets in the vicinity of the pro

burner must be properly grounded in

Accordance with local codes or, in the

absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code, CSA C22.1,

whichever is applicable.

Keep all electrical supply cords and fuel

supply hoses away from any heated surface

at all times.