General Regulaons

6

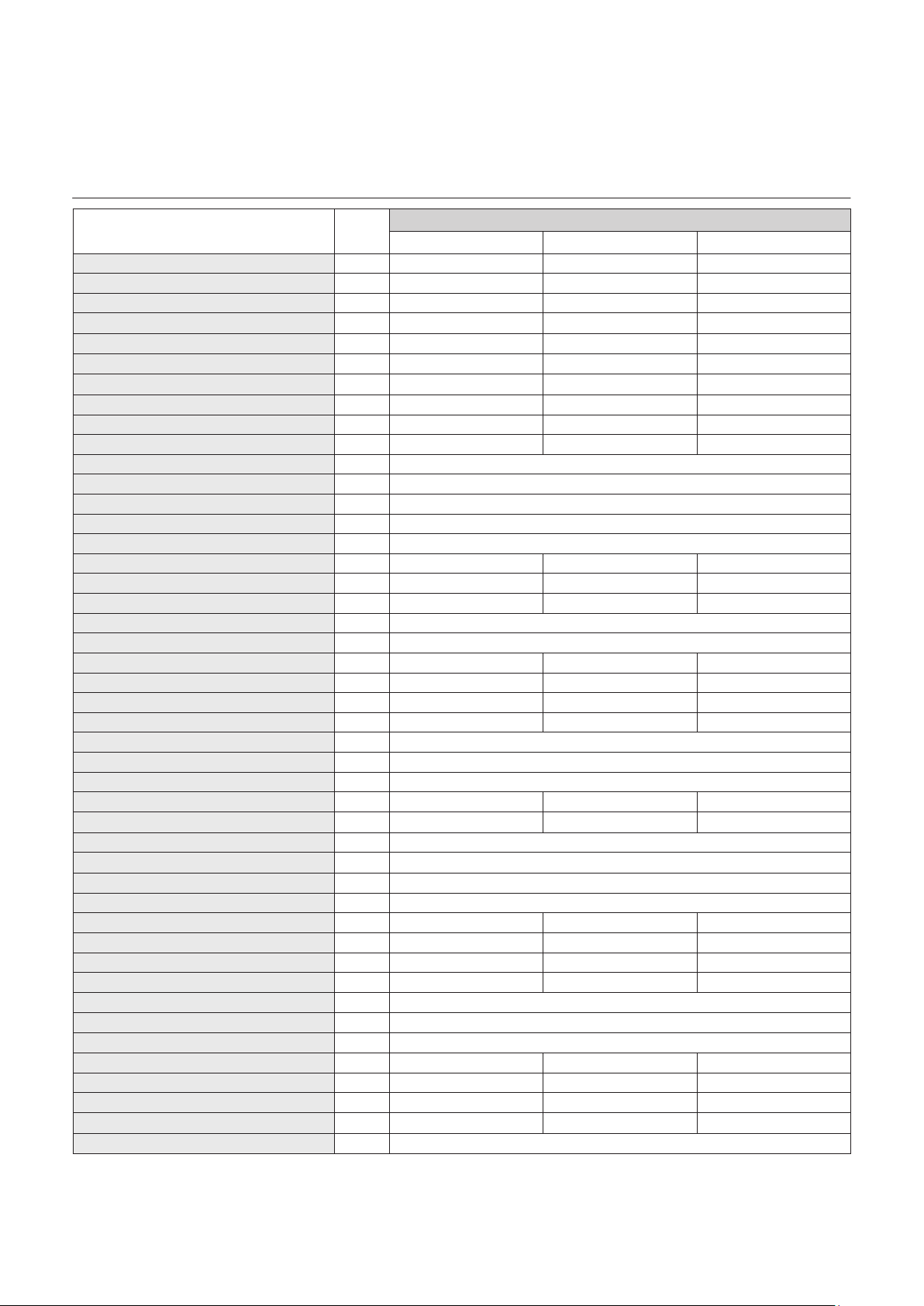

Applicaon

Norms and regulaons

This documentaon contains impor-

tant informaon, which is a base for

safe and reliable installaon, com-

missioning and operaon of the

boiler. All acvies described in this

document may only be executed by

authorized companies.

Changes to this document may be

eected without prior noce. We

accept no obligaon to adapt previ-

ously delivered products to incorpo-

rate such changes.

Only original spare parts may be

used when replacing components

on the boiler, otherwise warranty

will be void.

Applicaon

The boiler may be used for heang

and hot water producon purposes

only. The boiler should be connect-

ed to closed systems with a maxi-

mum temperature of 100 °C (high

limit temperature), maximum set

point temperature is 90 °C.

Norms and regulaons

When installing and operang the

boiler, all applicable norms (euro-

pean and local) should be fullled:

• Local building regulaons for in-

stalling combuson air and ue

gas systems;

• Regulaon for connecng the boil-

er to the electrical appliance;

• Regulaons for connecng the

boiler to the local gas network;

• Norms and regulaons according

to safety equipment for heang

systems;

• Any addional local laws/regula-

ons with regard to installing and

operang heang systems.

This boiler is CE approved and applies

to the following European standards:

• 1992 / 42 / EEC Boiler eciency

direcve.

• 2016 / 426 / EEC Gas appliance

regulaon.

• 2009/125/EC Direcve of the

European Parliament and of the

Council of 21 October 2009 estab-

lishing a framework for the seng

of ecodesign requirements for en-

ergy-related products.

• 811-813-814/2013 EU regulaon

• 2014 / 30 / EU The Electromag-

nec Compability (EMC) Direc-

ve.

• 2014 / 35 / EU Low Voltage Direc-

ve.

• EN 13203-2: 2015 (Gas-red do-

mesc appliances producing hot

water - Part 2: Assessment of en-

ergy consumpon).

• EN 15036-1: 2006 Heang boilers -

Test regulaons for airborne noise

emissions from heat generators

- Part 1: Airborne noise emissions

from heat generators.

• EN-ISO 3743-1: 2010 Acouscs

- Determinaon of sound power

levels and sound energy levels of

noise sources using sound pres-

sure - Engineering methods for

small movable sources in rever-

berant elds - Part 1: Comparison

method for a hard-walled test

room.

• EN 15502-1: 2012 +A1:2015 (Gas-

red heang boilers - Part 1: Gen-

eral requirements and tests).

• EN 15502-2-1: 2012 (Gas-red

central heang boilers - Part 2-1:

Specic standard for type C appli-

ances and type B2, B3 and B5 ap-

pliances of a nominal heat input

not exceeding 1000 kW).

• EN 60335-1 Household and similar

electrical appliances - Safety- Part

1: General requirements.

• EN 60335-2-102: 2016 Household

and similar appliances - Safety

- Part 2-102: Parcular require-

ments for gas, oil and solid-fuel

burning appliances having electri-

cal connecons.

• EN 55014-1: 2006 Electromag-

nec compability- Requirements

for household appliances, electric

tools and similar apparatus Part 1:

Emission A1:2009, A2:2011.

• EN 55014-2: 2015 Electromag-

nec compability- Requirements

for household appliances, electric

tools and similar apparatus Part 2:

Immunity - Product family stand-

ard.

• EN 61000-3-2: 2014 Electromag-

nec compability (EMC) Part 3-2:

Limits — Limits for harmonic cur-

rent emissions equipment input

current <= 16 A per phase.

• EN 61000-3-3: 2013 Electromag-

nec compability (EMC) Part

3-3: Limits — Limitaon of voltage

changes, voltage uctuaons and

icker in public low-voltage supply

systems, for equipment with rated

current <= 16 A per phase and not

subject to condional connecon.

Addional naonal standards

Germany:

• RAL - UZ 61 / DIN 4702-8

Switzerland:

• SVGW

Austria:

• 15a V-BG