ECM MOTORS

RENEWAIRE.COM ECM MOTOR SUPPLEMENTAL MANUAL 1.800.627.4499

8

PLANNING

YOUR INSTALLATION

INSTALLATION

To avoid motor bearing damage

and noisy and/or unbalanced

impellers, keep drywall spray,

construction dust, etc., out of unit.

CAUTION

1. Before servicing or cleaning the unit, switch

power off at disconnect switch or service panel

and lockout/tag-out to prevent power from being

switched on accidentally. More than one discon-

nect switch may be required to de-energize the

equipment for servicing.

2. This installation manual shows the suggested

installation method. Additional measures may be

required by local codes and standards.

3. Installation work and electrical wiring must be

done by qualified professional(s) in accordance

with all applicable codes, standards and

licensing requirements.

4. Any structural alterations necessary for instal-

lation must comply with all applicable building,

health, and safety code requirements.

5. This unit must be grounded.

6. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of

fuel burning equipment that might be installed in

the area affected by this equipment. If this unit

is exhausting air from a space in which chim-

neyvented fuel burning equipment is located,

take steps to assure that combustion air supply

is not affected. Follow the heating equipment

manufacturer’s requirements and the combustion

air supply requirements of applicable codes and

standards.

7. Use the unit only in the manner intended by the

manufacturer. If you have questions, contact

the manufacturer.

8. This unit is intended for general ventilating only.

Do not use to exhaust hazardous or explosive

materials and vapors. Do not connect this unit to

range hoods, fume hoods or collection systems

for toxics.

9. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

10. If installed indoors this unit must be properly

ducted to the outdoors.

RISK OF FIRE, ELECTRIC SHOCK, OR INJURY. OBSERVE ALL CODES AND THE FOLLOWING:

WARNING

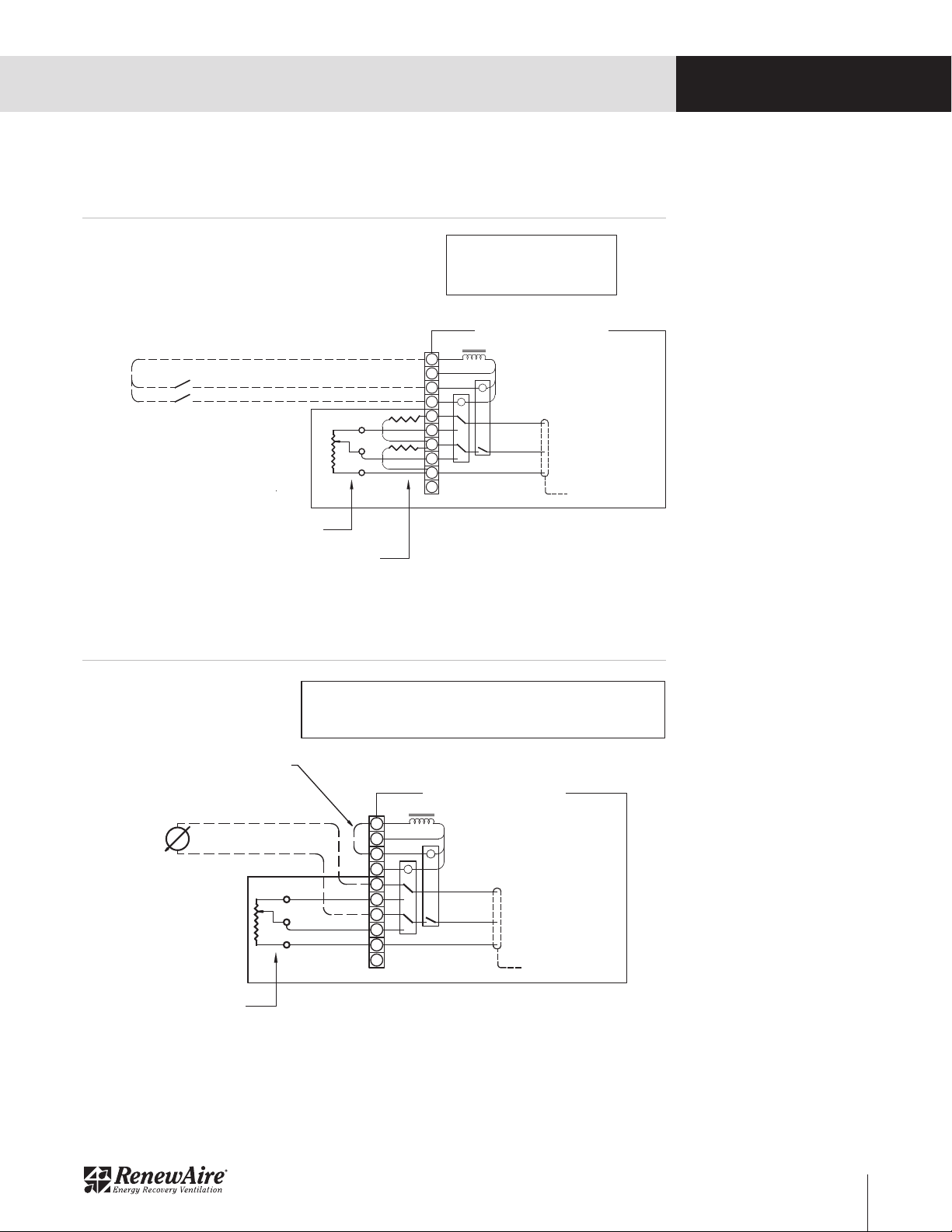

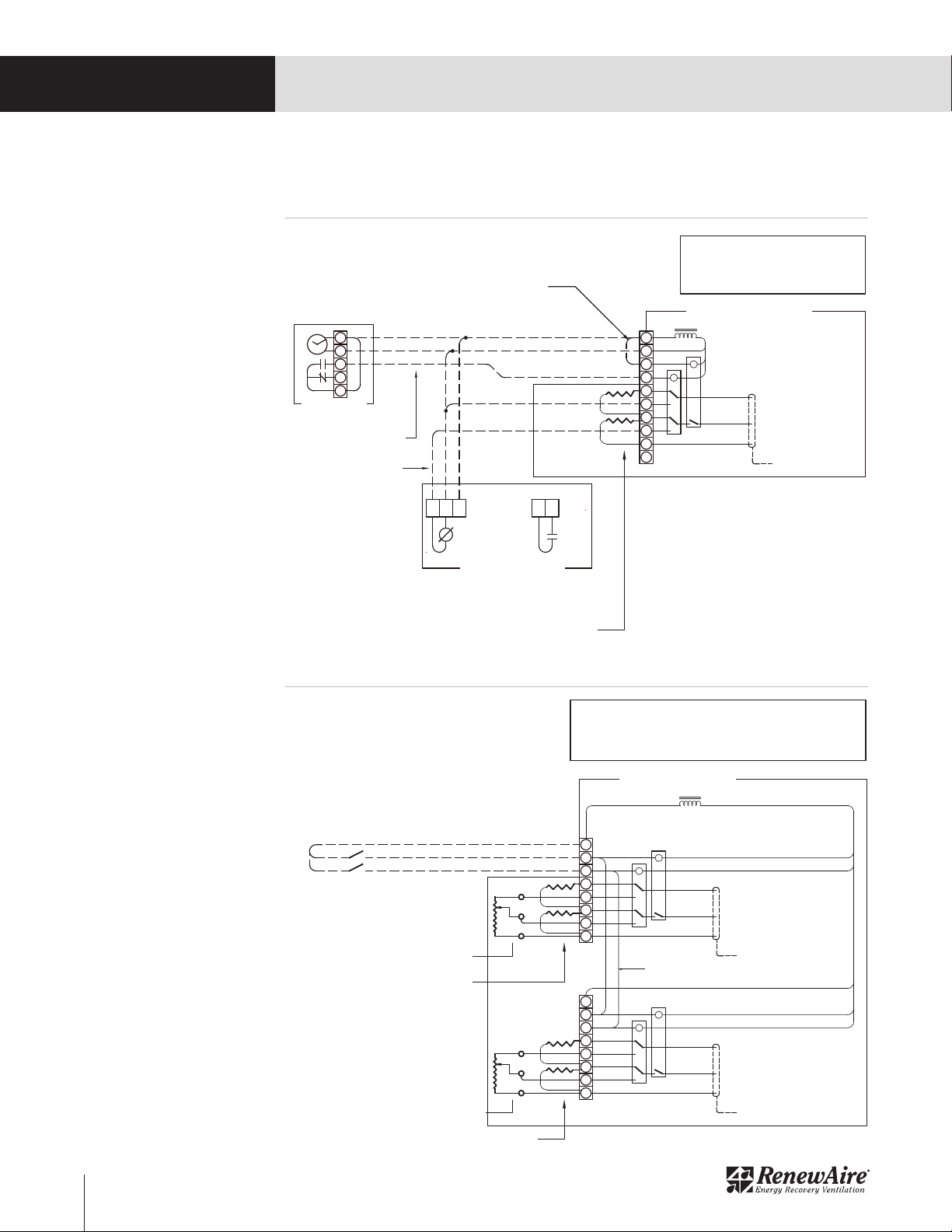

PRINCIPLES OF EXTERNAL CONTROL

The light commercial units with ECM motors are

designed for control by a wide variety of low voltage

(24VAC) controls to meet the ventilation needs of the

facility. These include time clock, occupancy sensor,

carbon dioxide sensor, building management system

(BMS) and others. These devices are commonly

known as 2-wire, 3-wire, and 4-wire devices. Re-

newAire offers separately the following for standalone

control of the ERV:

• Digital Time Clocks TC7D-W and TC7D-E

• Occupancy Sensors MC-C and MC-W

• Carbon Dioxide Sensor/Controllers CO2-W

and CO2-D

HE1X & HE1.5X ONLY

The external control device connects to the Light

Commercial unit to operate each blower independent-

ly or for one blower to act as leader and the other

blower to act as follower. When operating inde-

pendently, a single external switch or relay calls for

operation but each speed control motor can respond

independently to switch or analog signal source.

When acting as leader-follower, again, a single

external source calls for operation and then one motor

responds to the input signal. The Light Commercial

HE1X & HE1.5X units have the versatility that either

the exhaust air (EA) motor or the fresh air (FA) motor

can act as leader. Connection of an external control

device to the Light Commercial Unit is simple. All

external control device wires connect to a terminal

block(s) in the unit’s electrical box.