2

IMPORTANT: SAVE THESE INSTRUCTIONS

To the new owner:

We at REVERSO MFG. LTD. are pleased that you have chosen one of our products for

your home environment. We would like to take this opportunity to assure you that you

have chosen a top quality product which will provide you with all the warmth and charm

of a wood fireplace at the flick of a switch without any of the fuss and mess you would

normally associate with lighting a wood fire.

You can now enjoy many years of clean burning, trouble free operation, as well as, high

efficiency performance.

At REVERSO we have continued to deliver on our commitment to uncompromising

quality and time proven reliability. We stand proudly behind our entire wood and gas

burning products division, which are industry renowned by the brand name REVERSO

"SUPREME".

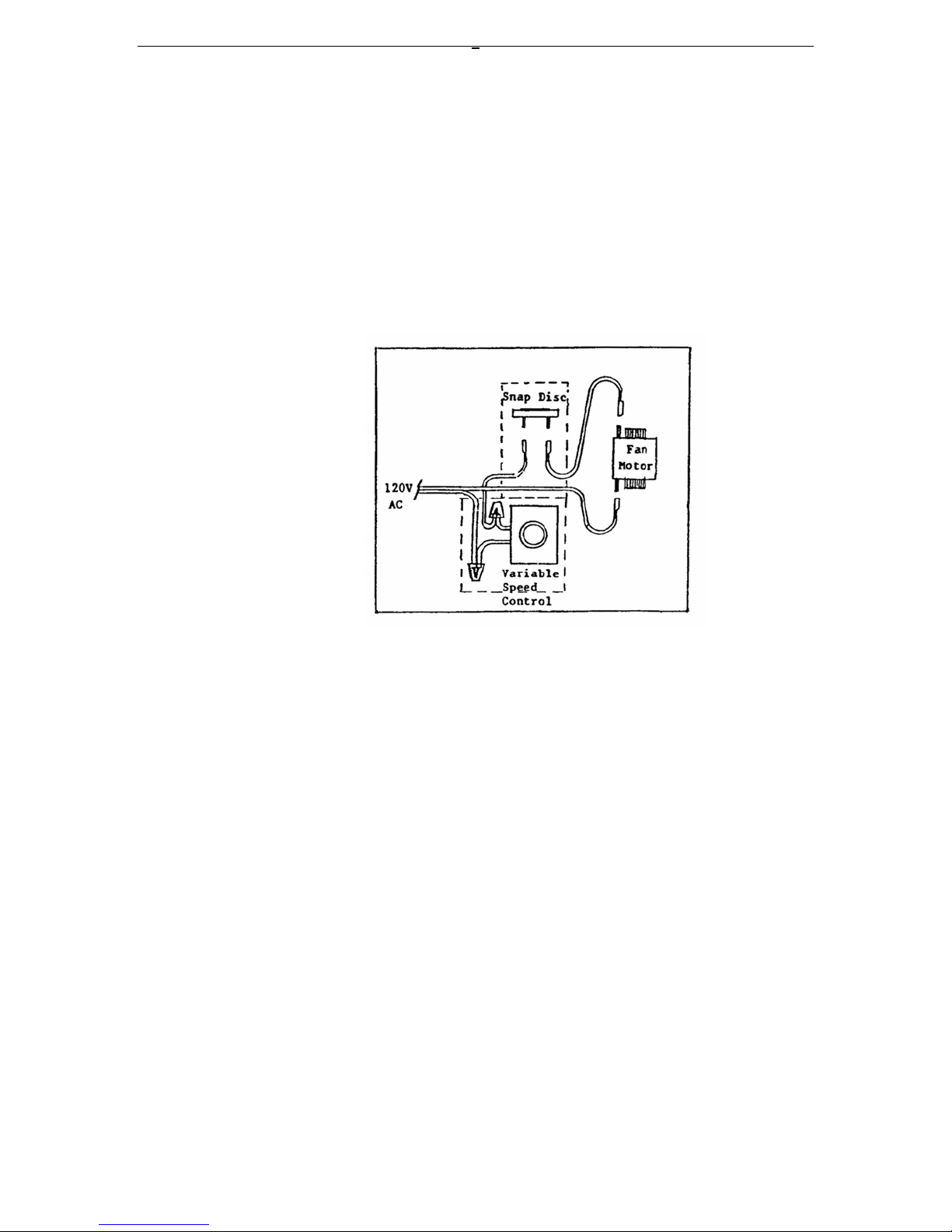

The REVERSO "SUPREME", DVF200 series of products incorporates heavy gauge

fireboxes, state of the art safety controls, and leak proof construction, all in an

aesthetically pleasing finished package. When setup correctly, the gas effects flames and

glowing embers bed offer what many people consider to be the most realistic simulated

wood fire available today. Some of the logs even include burn out effects and knot holes

which appear to have burned through and allow flames to lick out.

The logs employed in these units are manufactured with the latest space age ceramic fiber

material which products the glowing effects commonly associated with a wood fire but,

can be used over and over again for many years without showing any signs of wear.

All "REVERSO" products have been tested by Warnock Hersey to the national standards

of the Canadian and American Gas, Associations for both safety and efficiency.

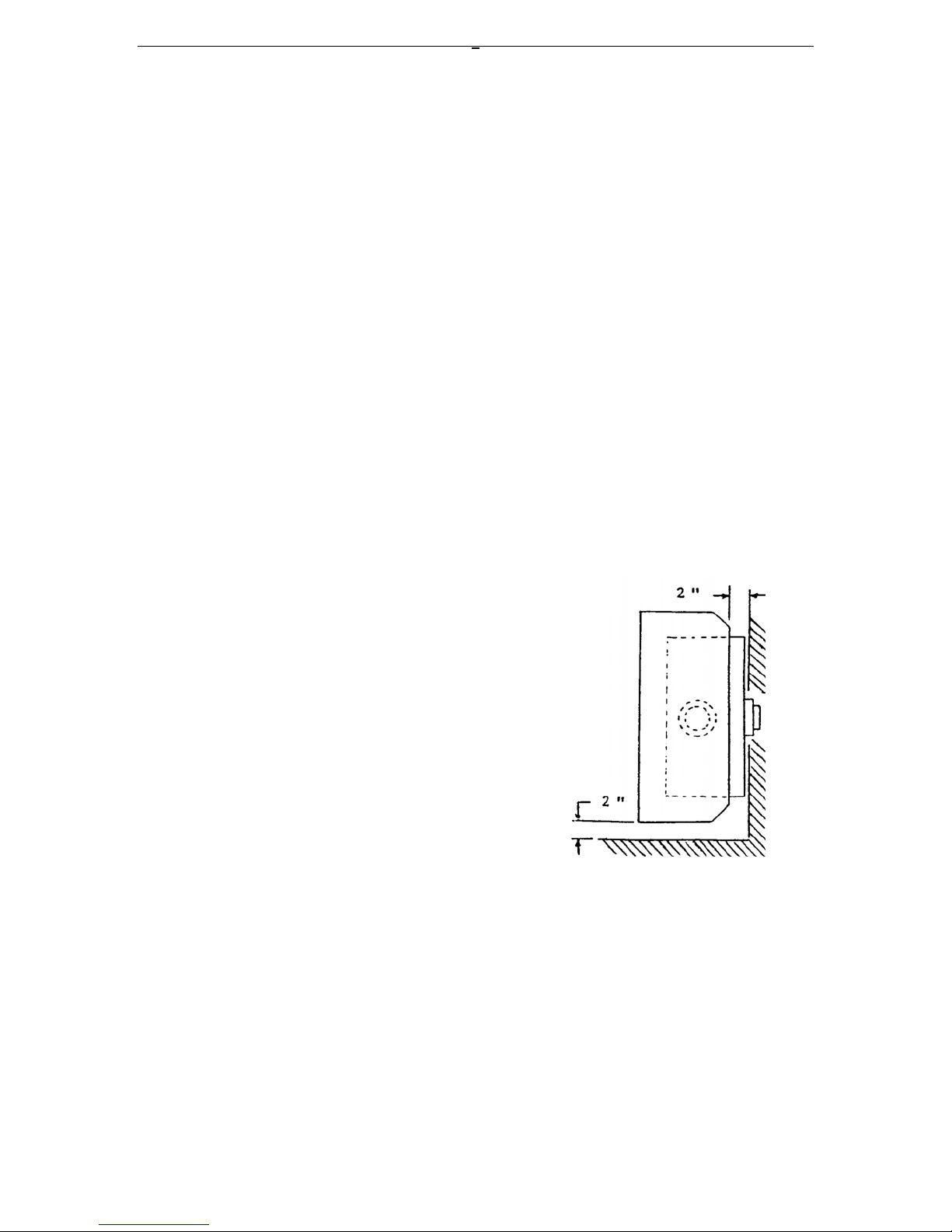

The DVF200 series direct vent gas fireplaces are also the most versatile fireplaces

available today, as they are approved for either top or rear venting, suiting sidewall or

rooftop applications. Since they arrive completely finished, inside and outside, the

DVF200 can be installed as either freestanding / non-recessed or as recessed (with

optional zero clearance kit).

Please take a moment now to acquaint yourself with these instructions and the many

features, such as the easy opening latched glass door, of your new "REVERSO" gas

fireplace.