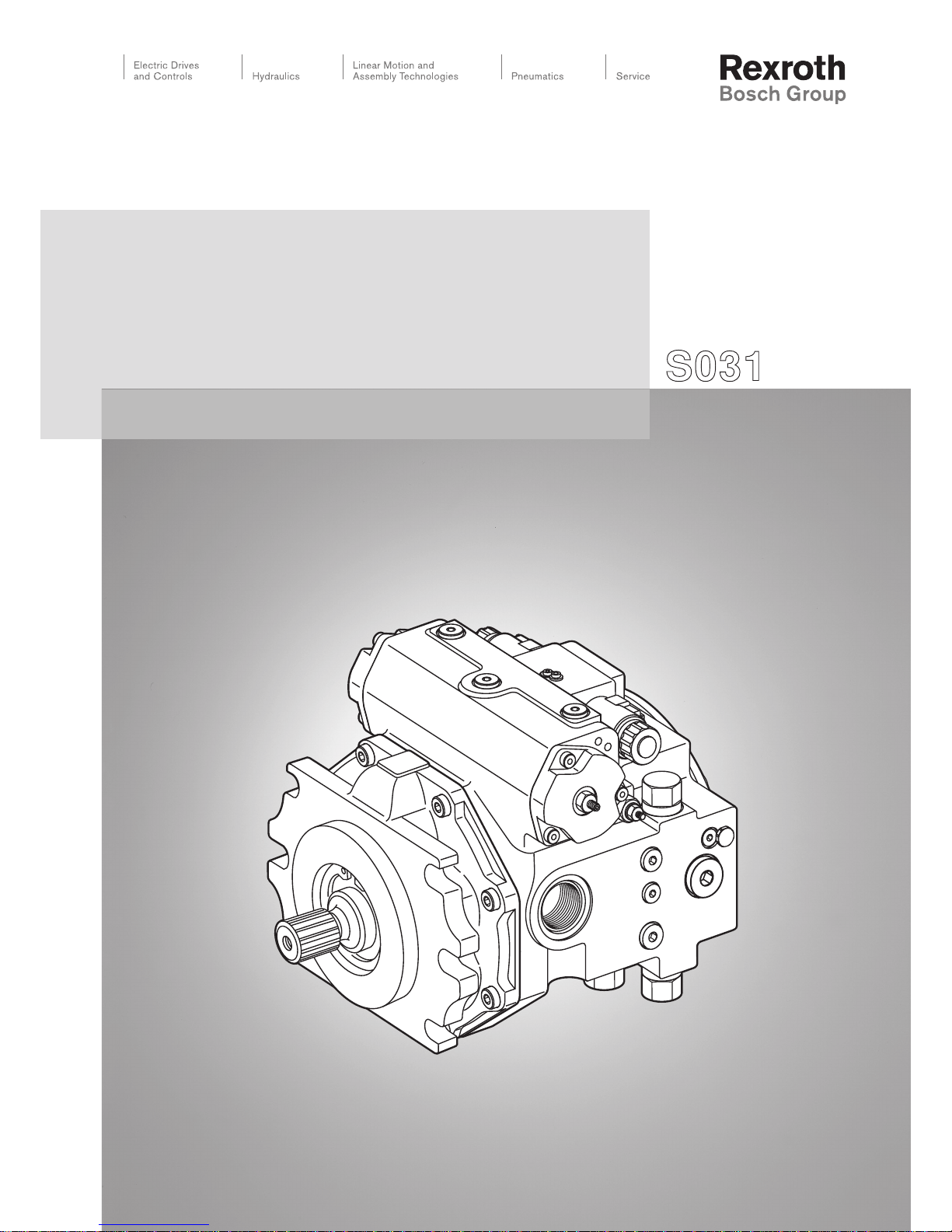

RE 92004-01-S031/08.2015 | A4VG Series 40 Bosch Rexroth AG 3/40

Contents

Inhalt

1 About this manual ..........................................................................................4

1.1 Related documents...................................................................................4

1.2 Abbreviations used ...................................................................................5

2 General safety instructions ...........................................................................6

2.1 Intended use .............................................................................................6

2.2 Improper use.............................................................................................6

2.3 Personnel qualifications............................................................................6

2.4 Safety instructions in this manual .............................................................7

2.5 Adhere to the following instructions ..........................................................7

2.6 Operator's obligations ...............................................................................9

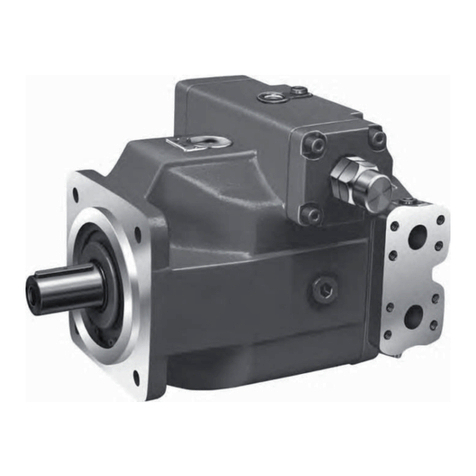

3 Product description......................................................................................10

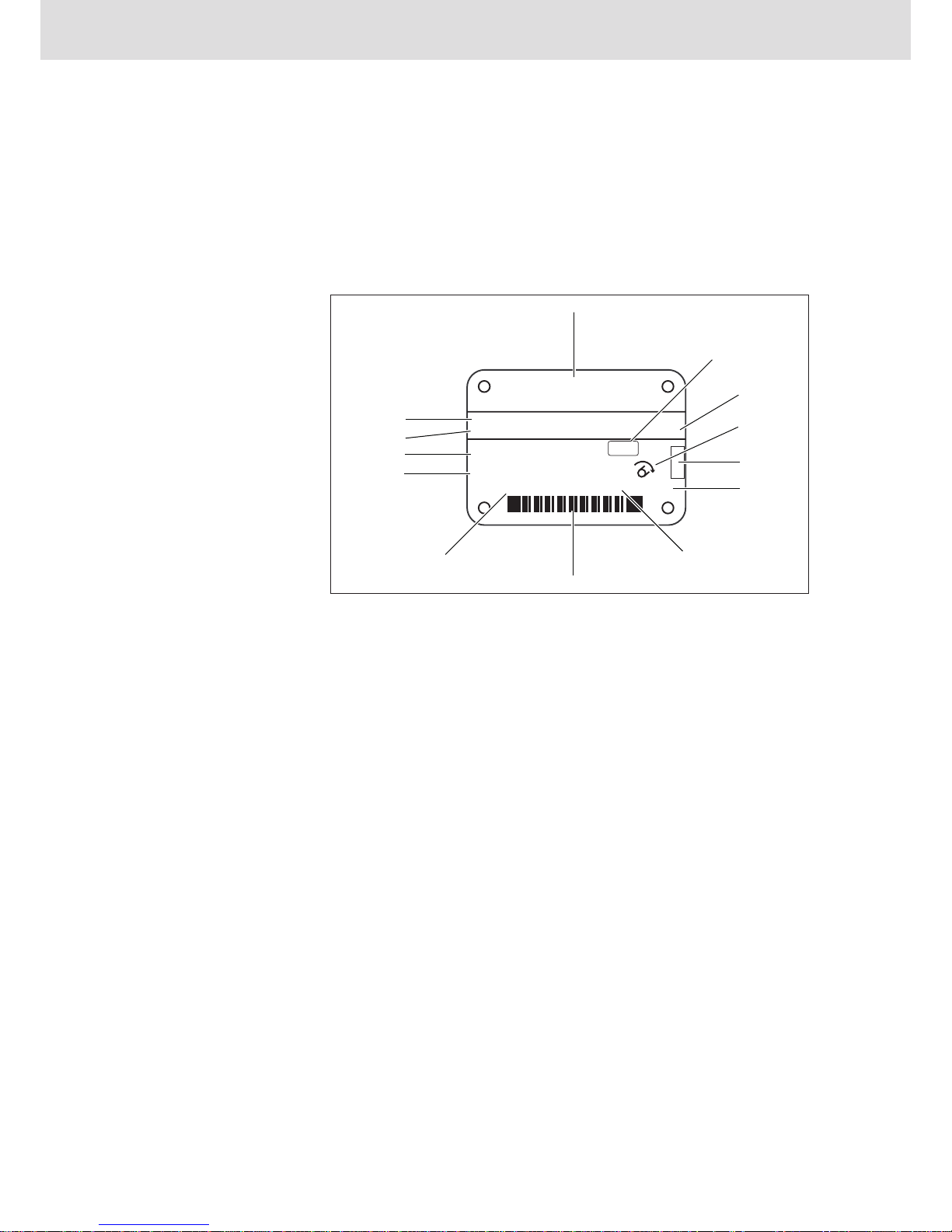

3.1 Name plate..............................................................................................10

3.2 Functional description.............................................................................11

3.3 Technical data.........................................................................................12

4 Controller.......................................................................................................13

4.1 Removing controller................................................................................13

4.2 Sealing controller ....................................................................................14

4.3 Installing the controller............................................................................15

4.4 Setting controller (hydraulic neutral position)..........................................16

5 Internal gear pump .......................................................................................17

5.1 Remove internal gear pump cover..........................................................17

5.2 Seal/install internal gear pump cover......................................................18

6 Shaft seal.......................................................................................................19

6.1 Exchange shaft seal................................................................................19

7 Valves ............................................................................................................20

7.1 Seal/replace the high pressure relief valve.............................................20

7.2 Seal/replace low pressure relief valve ....................................................22

7.3 Seal/replace pressure cut-off..................................................................24

7.3.1 Set pressure cut-off .......................................................................25

7.4 Seal control cartridge..............................................................................26

7.4.1 Set beginning of control .................................................................27

7.5 Seal shuttle valve....................................................................................28

7.6 Exchange angle position sensor.............................................................29

8 Filter ...............................................................................................................30

8.1 Mountable filter .......................................................................................30

8.2 Seal/replace filter head ...........................................................................31

9 Threaded plugs .............................................................................................32

9.1 Seal/replace threaded plugs ...................................................................32

10 Settings..........................................................................................................34

10.1 Low pressure ..........................................................................................35

10.2 High pressure..........................................................................................36

10.3 Tightening torques ..................................................................................37