4016 Harry Hines Blvd Dallas, Texas 75219 • 972-650-1855

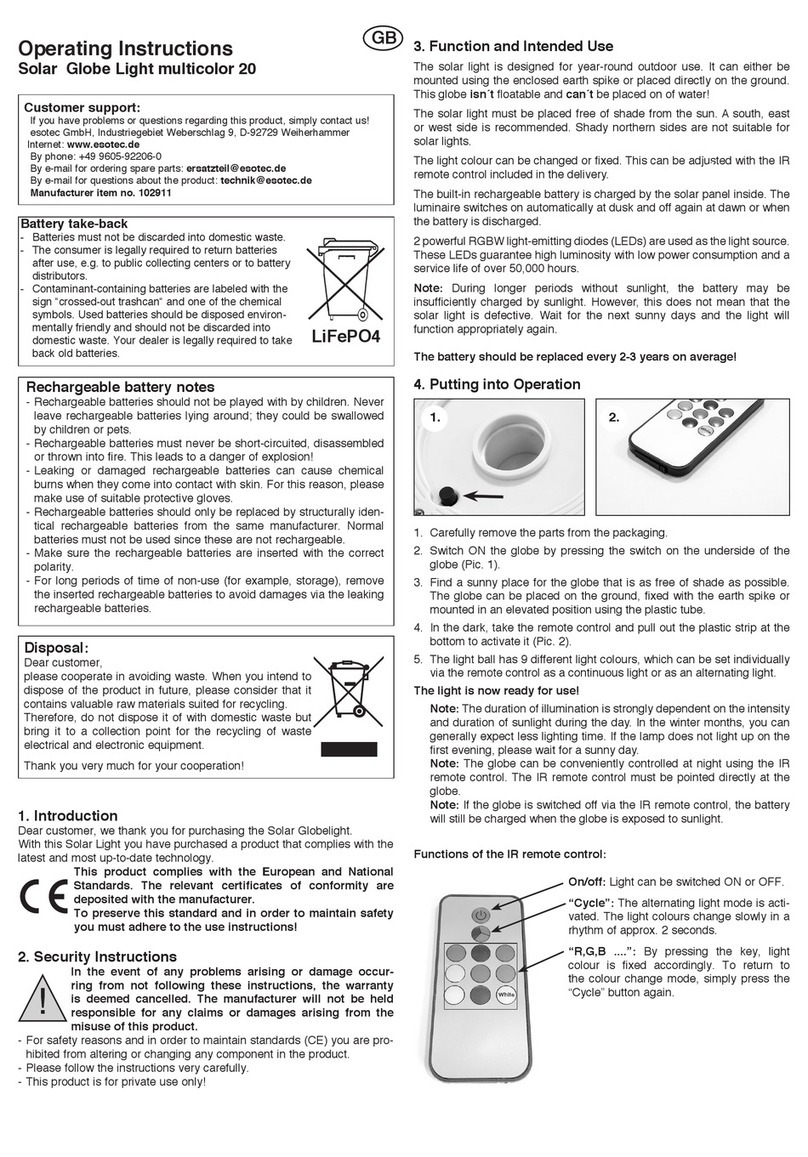

LED RGB ColorFlex

LED Cove Lighting

Read all instructions

DISCONNECT POWER BEFORE INSTALLING OR CUTTING!

1. Cut ColorFlex light only on the marked intervals. Cut in the center. It is easier to cut the back side where there are no solder points.

2. Carefully remove the PVC as in picture with sharp blade but do not cut the PCB. Cut the clear PVC back to reveal the full Copper connectors. The

Copper connectors should be 6 to 7 mm exposed from the PVC (tongue connectors). Carefully note that the connection points must line up. V1 to V1, G

to G, R to R and so on.

G

R

B

V1 and V2 are positive (+) pole of LEDs (white wires).

Seal end cap by heat shrink or glue

Note: 5 wires RGB

-V1, V2: White wires (2x) Positive

-B: Blue Wire (-)

-G: Green wire (-)

-R: Red (-)

Silicone

P 1/2

Do not bend sideways

Flexible on one axis

Deflection:

The bend radius must not

exceed150mm (6”)

150 mm

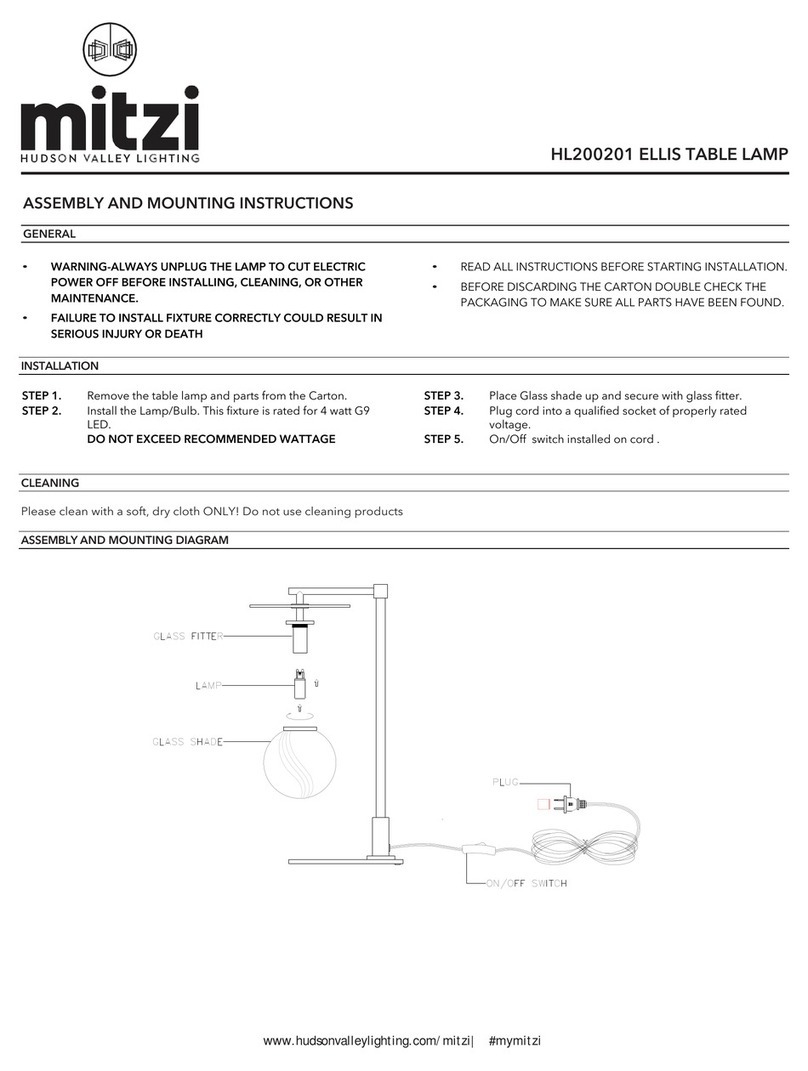

Step 3: Inspect the plastic connector housing to ensure the metal tabs in the plastic housing are:

Still in place, uniform in shape & springy.

Step 4: Place RGB Border Light in the bottom plastic connector housing.

Step 5: Place the black wire connector assembly in the other side of the bottom plastic connector housing.

Step 6: Ensure that the connectors do not touch one another when in the plastic housing.

Step 7: Test fit the upper plastic connector housing. Ensure that it will comfortably fit and that the metal tabs of the upper and lower plastic connector

housing will touch the copper connectors on all sides.

Step 8: Screw the connector together using a criss-cross pattern to ensure uniform and even pressure on the connecter while screwing it together.

Step 9: Test the RGB strip by lighting one color at a time.

Note the following when testing:

Both White wires are both positive and both need to be connected to the positive

The color of the wires should reflect the color of the lights

Test the RGB strip by lighting one color at a time.

If Green lights up when the blue should light up and the Blue lights up when the Green should light up then flip the black wire connector assembly

over inside the plastic housing and retest.

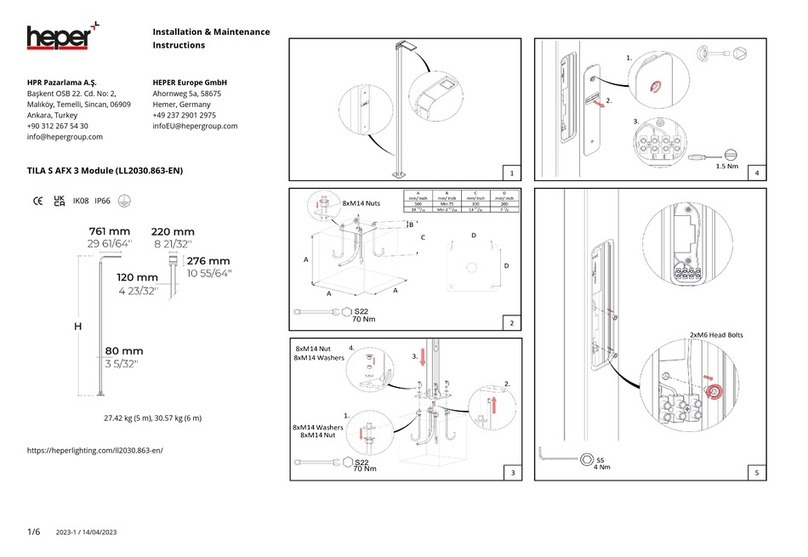

WARNING: ONLY QUALIFIED PERSONNEL SHOULD PERFORM INSTALLATION.

TO AVOID ELECTRICAL SHOCK OR COMPONENT DAMAGE, DISCONNECT POWER BEFORE ATTEMPTING INSTALLATION OF THE POWER

SUPPLIES AND/OR LED BORDER LIGHT

DISCONNECT POWER BEFORE INSTALLING OR SERVICING!

When using power supplies; the following basic safety features should be verified in addition to any other application

specific concerns and local safety codes:

Short circuit protection

Overload protection

Overheat protection

Correct wire gauge

Correct output voltage, including consideration for ripple and spikes.