THE MANUFACTURER’S WARRANTY

DOES NOT COVER ANY DAMA E OR

DEFECT TO THE AIR CONDITIONER

CAUSED BY THE ATTACHMENT OR

USE OF ANY COMPONENTS, ACCES-

SORIES OR DEVICES (OTHER THAN

THOSE AUTHORIZED BY THE MANU-

FACTURER) INTO, ONTO OR IN CON-

JUNCTION WITH THE AIR CONDI-

TIONER. YOU SHOULD BE AWARE

THAT THE USE OF UNAUTHORIZED

COMPONENTS, ACCESSORIES OR

DEVICES MAY ADVERSELY AFFECT

THE OPERATION OF THE AIR CONDI-

TIONER AND MAY ALSO ENDAN ER

LIFE AND PROPERTY. THE MANU-

FACTURER DISCLAIMS ANY

RESPONSIBILITY FOR SUCH LOSS

OR INJURY RESULTIN FROM THE

USE OF SUCH UNAUTHORIZED

COMPONENTS, ACCESSORIES OR

DEVICES.

3

CHECKING RODUCT RECEIVED

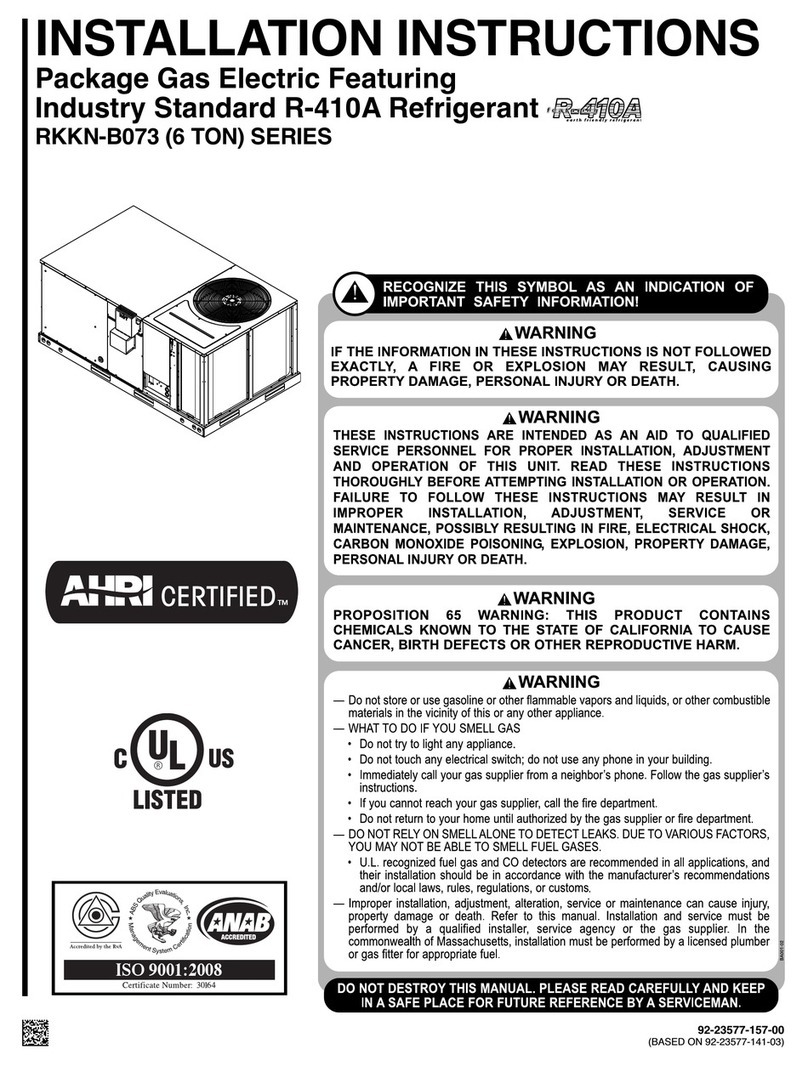

This booklet contains the installation and operating instructions for your combination

gas heating/electric cooling unit. There are some precautions that should be taken to

derive maximum satisfaction from it. Improper installation can result in unsatisfactory

operation or dangerous conditions.

Read this booklet and any instructions packaged with separate equipment required

to make up the system prior to installation. Give this booklet to the owner and explain

its provisions. The owner should retain this booklet for future reference.

EQUI MENT ROTECTION FROM THE

ENVIRONMENT

Upon receiving the unit, inspect it for any damage from shipment. Claims for dam-

age, either shipping or concealed, should be filed immediately with the shipping com-

pany. IMPORTANT: Check the unit model number, heating size, electrical character-

istics, and accessories to determine if they are correct.

I. S ECIFICATIONS

A. GENERAL

The Rheem H2AC Rooftop Unit Combination Gas Heating/Electric Cooling Rooftop

with integrated Potable Water Heating is available in 250,000 BTUH and 350,000

BTUH gas heating inputs. Cooling capacity is 15 nominal tons.

Potable water heating capacities range from approximately 117,000 BTUH to

145,000 BTUH depending on water temperature, indoor air temperatures, and indoor

CFM.

Units are designed for downflow-only supply and return air and are weatherized and

intended for outdoor installation.

Since the waste-heat recovery/water heating feature of the H2AC Rooftop Unit only

functions during the cooling mode, the unit should be installed to serve the area of

the structure having the largest cooling run-time load, for instance the kitchen area of

the restaurant, in order to provide the greatest water heating and energy saving ben-

efits.

B. MAJOR COM ONENTS

The typical unit includes a hermetically-sealed refrigerating system consisting of a

scroll compressor, condenser coil, evaporator coil with TXV, a circulation air blower, a

condenser fan, a refrigerant to air heat exchanger assembly, a refrigerant to water

heat exchanger, 3-way valve, and 2 solenoid valves, gas burner and control assem-

bly, combustion air motor and fan, and all necessary internal electrical wiring. The

cooling systems of these units are factory-evacuated, charged and performance test-

ed. Refrigerant amount and type are indicated on rating plate.

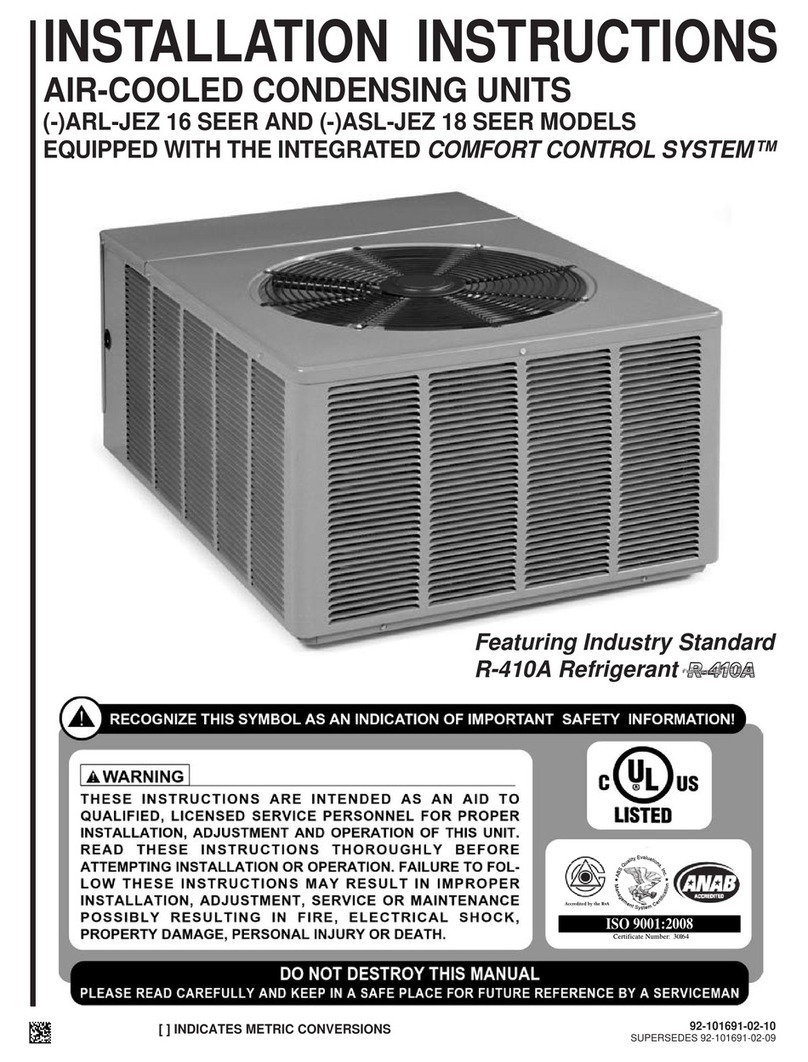

C. R410A REFRIGERANT

All units are factory charged with R-410A refrigerant.

1. Specification of R-410A:

Application: R-410A is not a drop-in replacement for R-22;equipment designs must

accommodate its higher pressures. It cannot be retrofitted into R-22 units.

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than R-

22. Recovery and recycle equipment, pumps, hoses, and the like need to have design

pressure ratings appropriate for R-410A. Manifold sets need to range up to 800 psig

high-side and 250 psig low-side with a 550 psig low-side retard. Hoses need to have a

service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig service

pressure rating. OT 4BA400 or OT BW400.

Combustibility: At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible. R-410A and air should never be mixed in tanks or supply

lines, or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air. Leak checking can be performed safely with

nitrogen or a mixture of R-410A and nitrogen.

Recognize this symbol as an

indication of Important Safety

Information!

!

UNITS ARE NOT DESI N CERTIFIED

TO BE INSTALLED INSIDE THE

STRUCTURE. DOIN SO CAN

CAUSE INADEQUATE UNIT PER-

FORMANCE AS WELL AS PROPERTY

DAMA E AND CARBON MONOXIDE

POISONIN RESULTIN IN PERSON-

AL INJURY OR DEATH.

sWARNING

!

PROVIDE ADEQUATE COMBUSTION

AND VENTILATION AIR TO THE UNIT

SPACE AS SPECIFIED IN THE COM-

BUSTION AND VENTILATION AIR

SECTION OF THESE INSTRUCTIONS.

sWARNING

!

sWARNING

!

!WARNIN

EFFICIENCY TESTIN NOTICE

FOR PURPOSES OF VERIFYIN OR

TESTIN EFFICIENCY RATIN S, THE

TEST PROCEDURE IN TITLE 10 PART

431 APPENDIX A TO SUBPART F

(UNIFORM TEST METHOD FOR

MEASURIN THE ENER Y

CONSUMPTION OF SMALL LAR E

AND VERY LAR E COMMERCIAL

PACKA E AIR CONDITIONIN AND

HEATIN EQUIPMENT), TITLE 10

PART 431.76 SUBPART D (UNIFORM

TEST METHOD FOR MEASURIN

ENER Y CONSUMPTION OF

COMMERCIAL WARM AIR

FURNACES), AND THE CLARIFYIN

PROVISIONS PROVIDED IN THE

AHRI OPERATIONS MANUALS FOR

UNITARY LAR E EQUIPMENT

340/360, 365 AND COMMERCIAL

FURNACES THAT WERE APPLICA-

BLE AT THE DATE OF MANUFAC-

TURE SHOULD BE USED FOR TEST

SET UP AND PERFORMANCE.