TABLE OF CONTENTS

SAFETYSECTION ......................................................................................................................................... 1-1

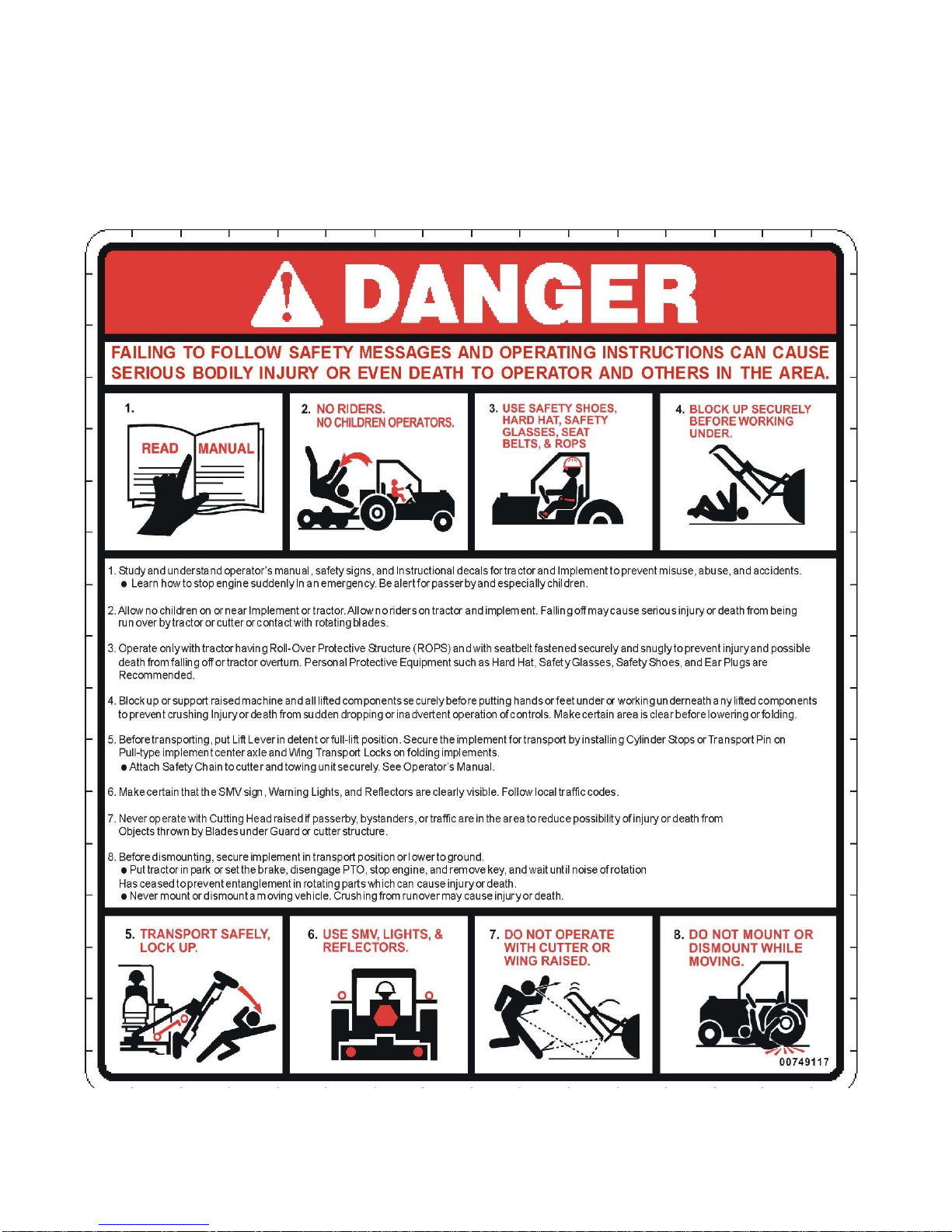

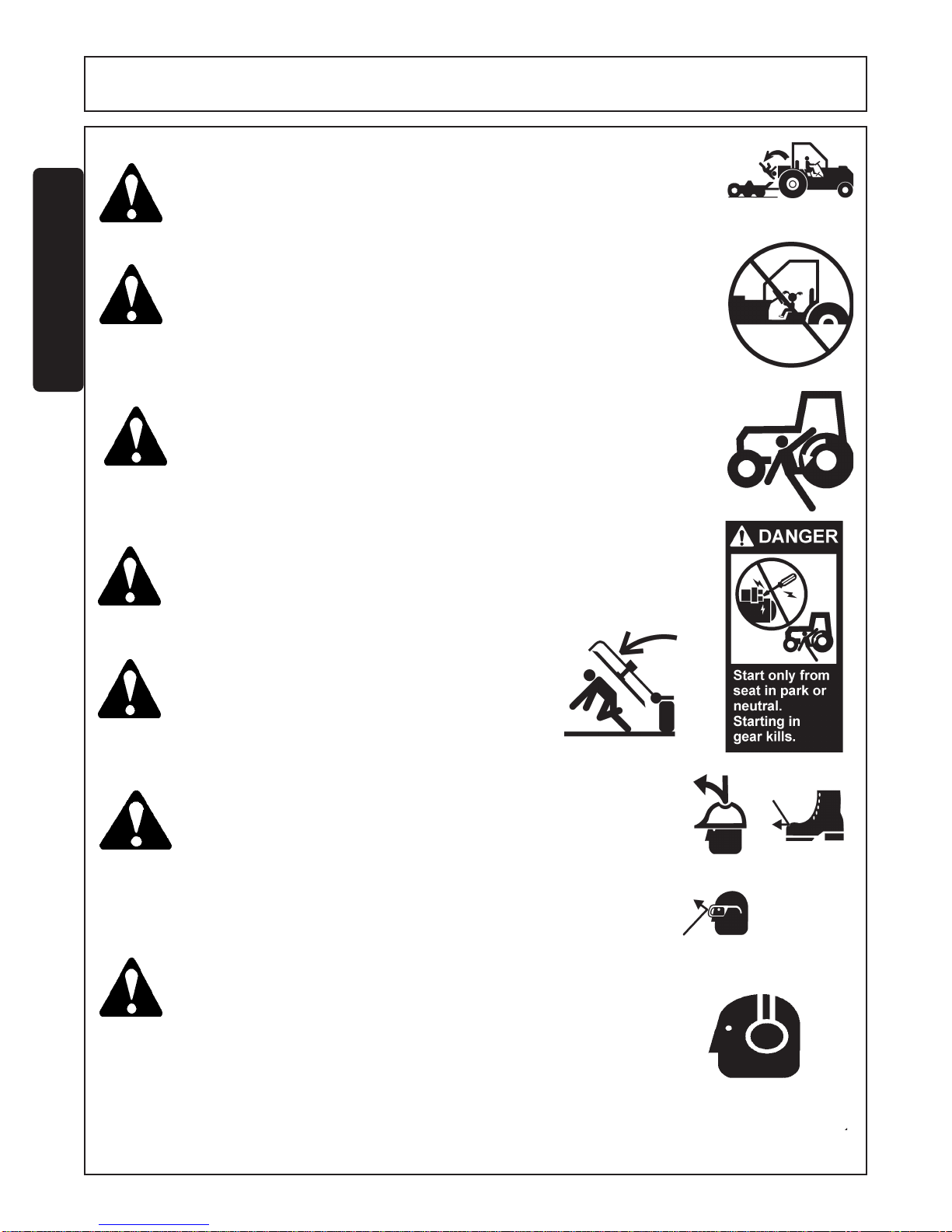

SafetyInformation ........................................................................................................................................... 1-2

DecalLocation.............................................................................................................................................. 1-11

SafetyDecals ............................................................................................................................................... 1-12

Federal Laws & Regulations ............................................................................................................... 1-14

INTRODUCTIONSECTION ............................................................................................................................ 2-1

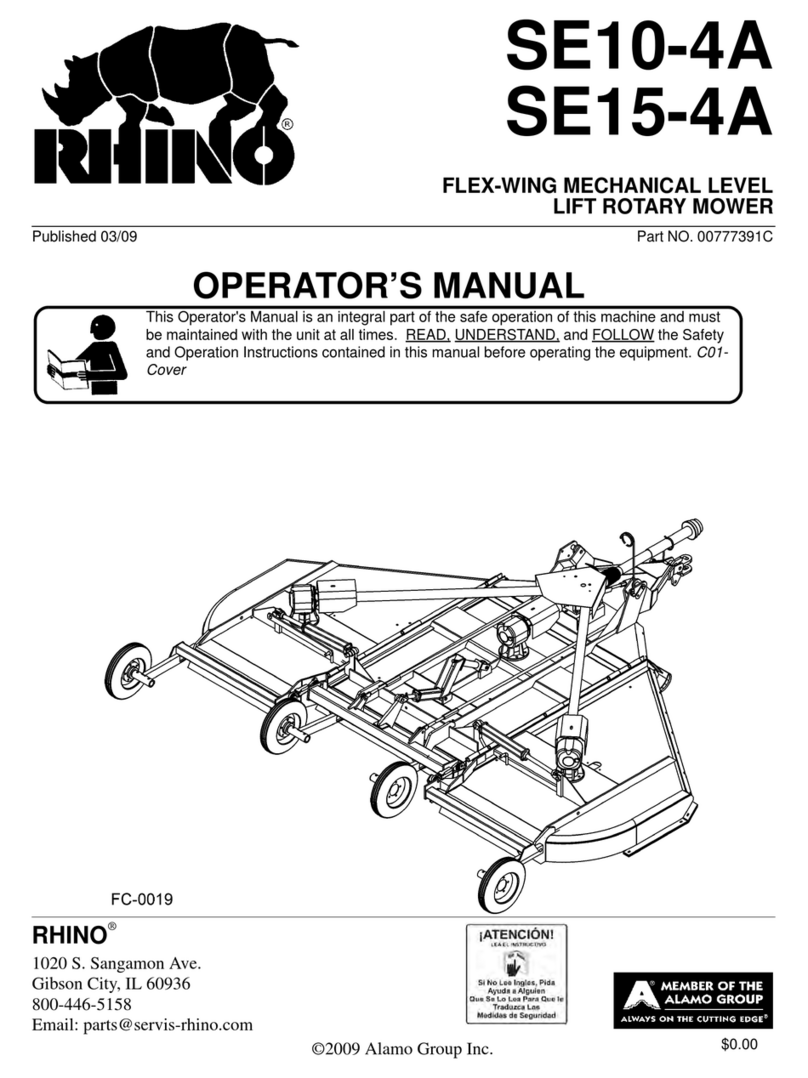

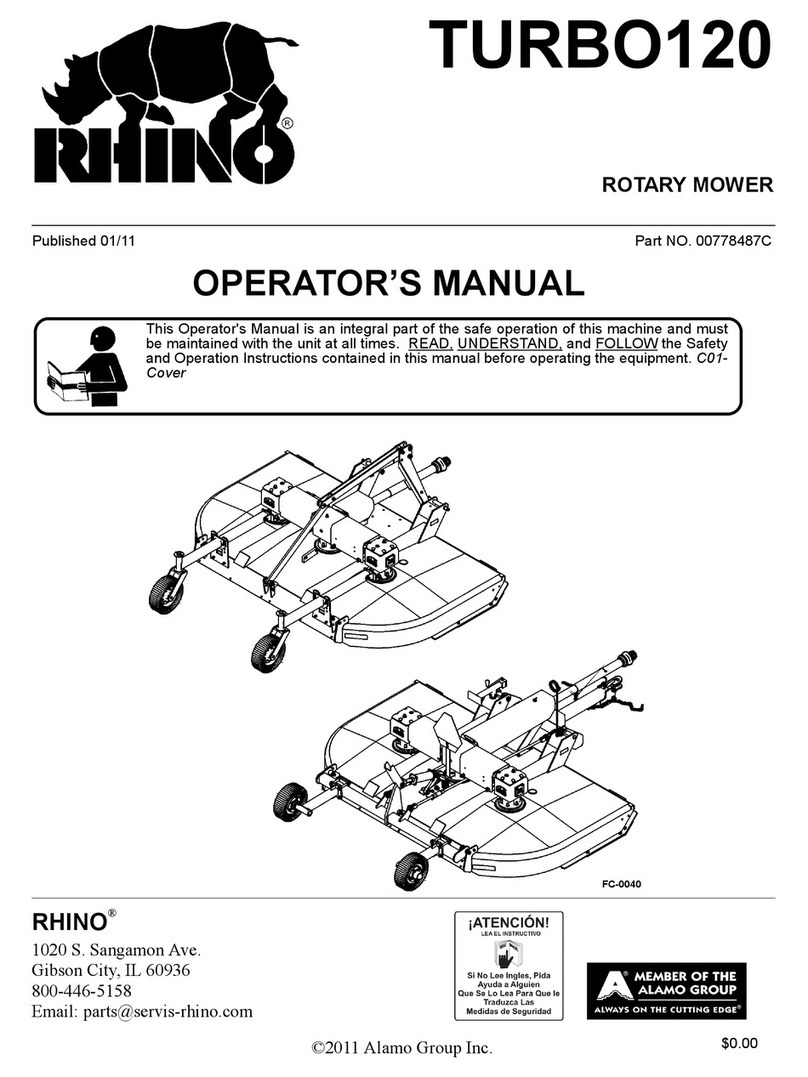

ASSEMBLY SECTION ..................................................................................................................................3-1

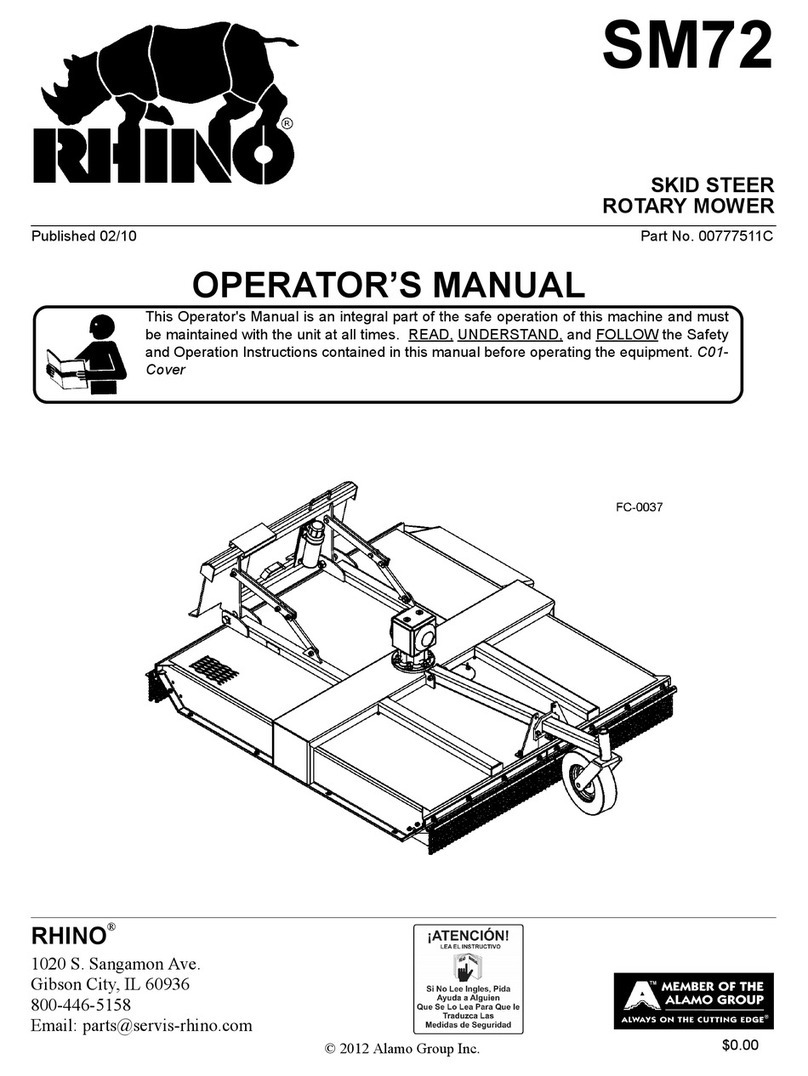

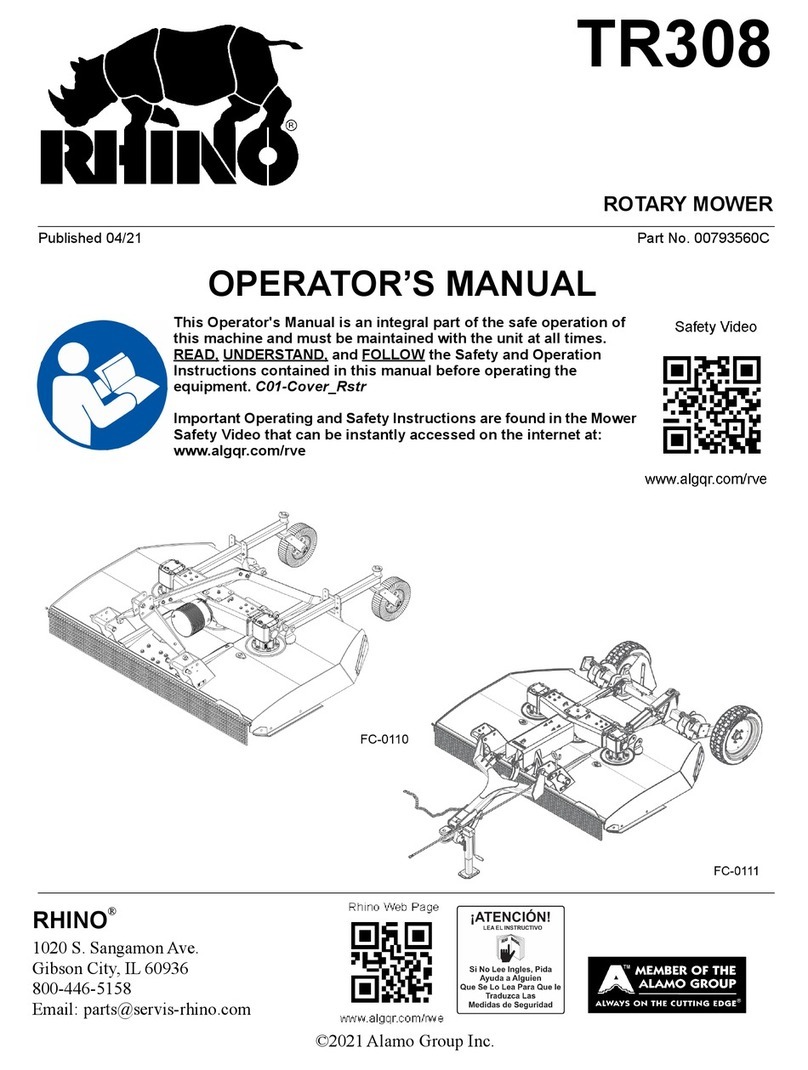

A-Frame Attachment ......................................................................................................................................3-2

Caster Wheel Attachments ............................................................................................................................3-3

Discharge Chute Installation ..........................................................................................................................3-4

Driveline Attachment ......................................................................................................................................3-4

OPERATION SECTION .................................................................................................................................4-1

Tractor Preparation ........................................................................................................................................4-2

Attaching Mower to Tractor ............................................................................................................................4-2

Driveline Attachment to Tractor......................................................................................................................4-3

Cutting Height Adjustment .............................................................................................................................4-3

Starting & Stopping Cutter..............................................................................................................................4-3

Cutting Speed.................................................................................................................................................4-4

Cutting Tips ....................................................................................................................................................4-4

DetachingandStoring..................................................................................................................................... 4-5

DrivelineLengthCheckProcedure .................................................................................................................. 4-5

FrontGaugeWheelInterferenceCheck .......................................................................................................... 4-6

Troubleshooting .............................................................................................................................................. 4-7

MAINTENANCE SECTION ............................................................................................................................5-1

Lubrication Information...................................................................................................................................5-2

Gearbox .........................................................................................................................................................5-3

Gauge Wheel Assemblies..............................................................................................................................5-3

DrivelineLubrication.......................................................................................................................................5-4

Blade Spindle Lubrication...............................................................................................................................5-4

Blade Servicing ..............................................................................................................................................5-5

BladeSharpening...........................................................................................................................................5-5

Blade Removal and Installation......................................................................................................................5-5

Belt Adjustment Procedure ............................................................................................................................5-6

BeltRemoval/Installation................................................................................................................................. 5-6

Storage ........................................................................................................................................................... 5-7

TorqueSettings .............................................................................................................................................. 5-7

BladeSpindleServiceInstructions.................................................................................................................. 5-8