Riccar Serger User manual

Other Riccar Sewing Machine manuals

Riccar

Riccar LEGACY R3100 Technical manual

Riccar

Riccar 9900 User manual

Riccar

Riccar 749L User manual

Riccar

Riccar 1900 User manual

Riccar

Riccar SUPER STRETCH 888 User manual

Riccar

Riccar 650 User manual

Riccar

Riccar R950 User manual

Riccar

Riccar R651 User manual

Riccar

Riccar R1926 User manual

Riccar

Riccar R700 User manual

Riccar

Riccar 610 User manual

Riccar

Riccar Super Stretch 410 User manual

Riccar

Riccar R552 User manual

Riccar

Riccar REC6000 User manual

Riccar

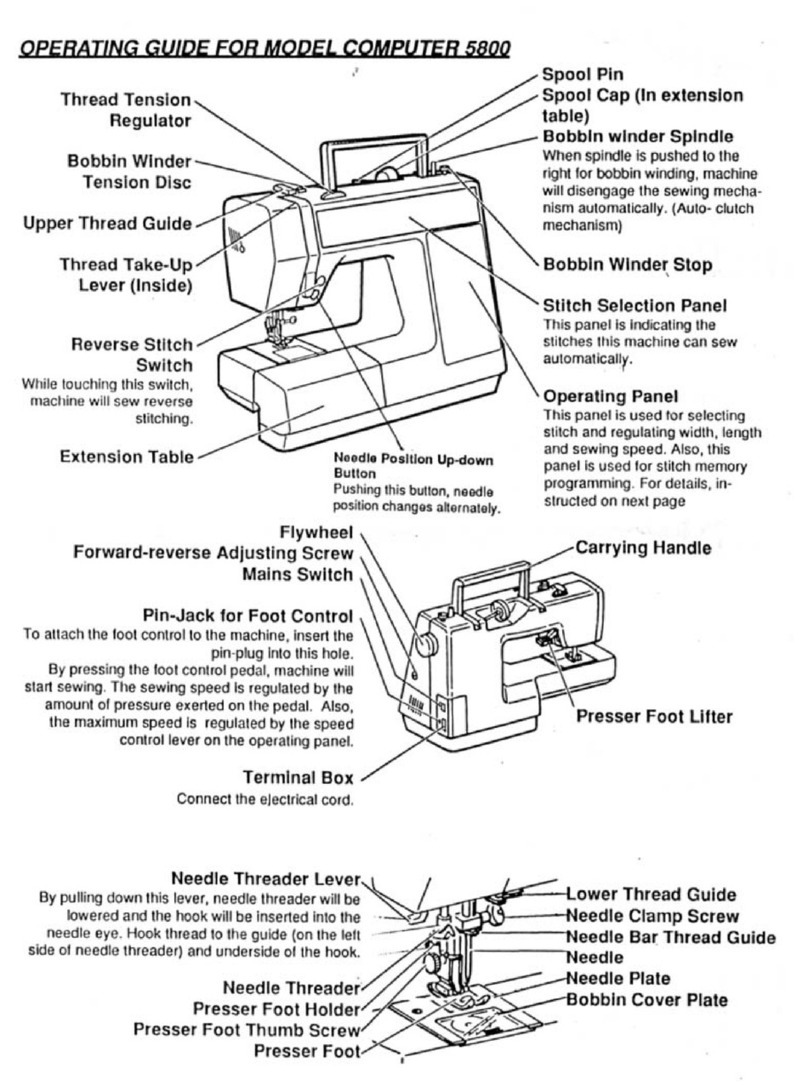

Riccar 5800 User manual

Riccar

Riccar 3600 User manual

Riccar

Riccar BL2000 User manual

Riccar

Riccar 706 User manual

Riccar

Riccar Serger IBRL613 User manual

Riccar

Riccar 808E User manual