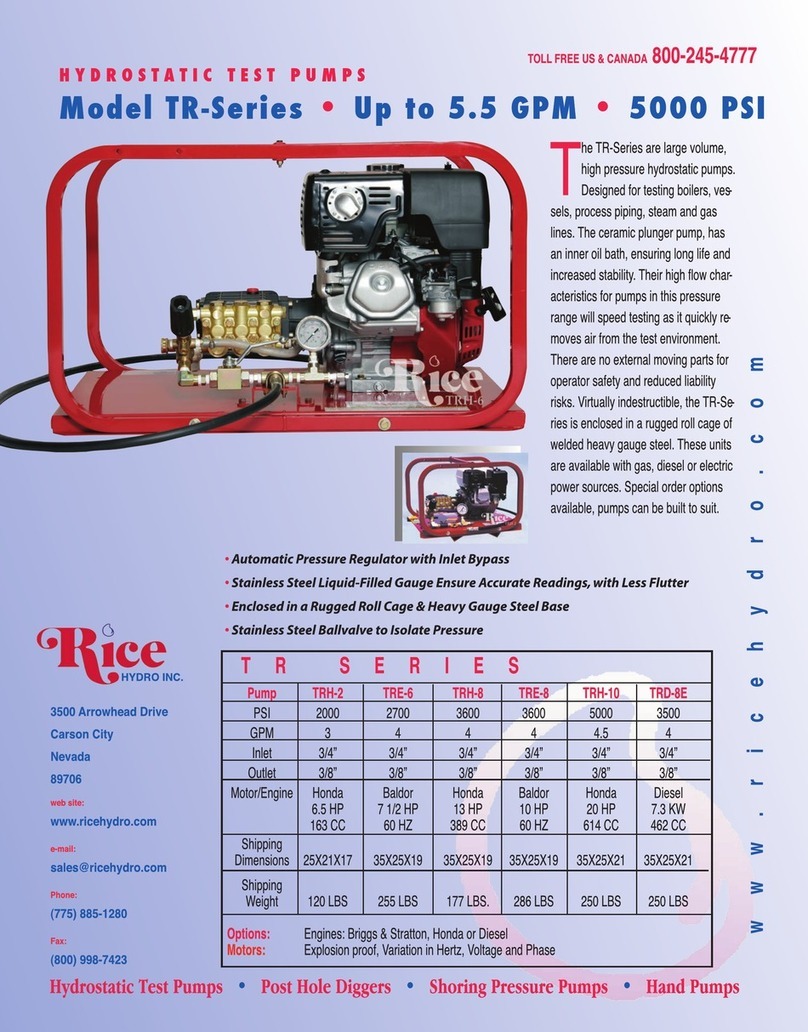

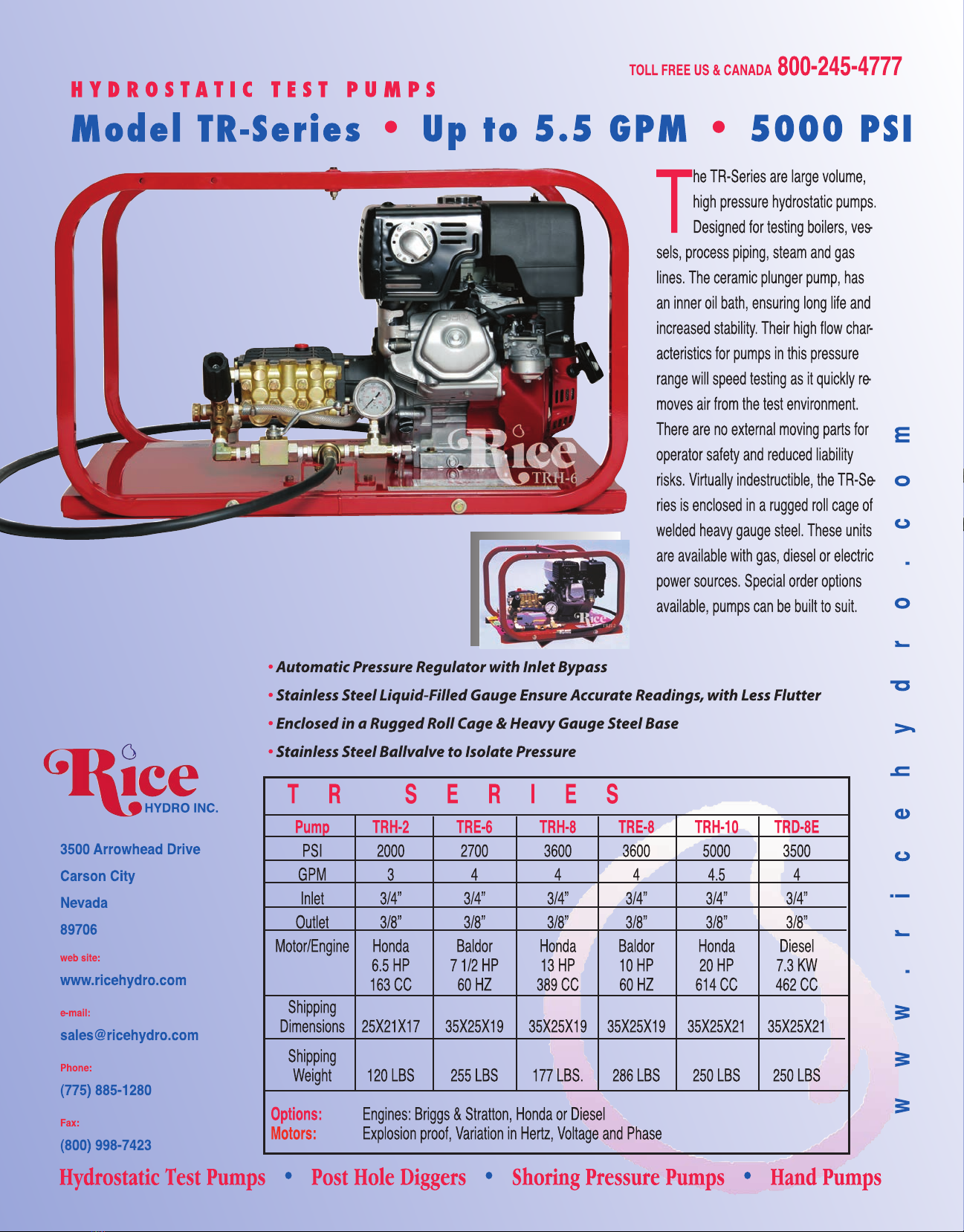

RICE HYDRO, INC. - MANUFACTURER'S OPERATING INSTRUCTIONS

TR-SERIES MODEL TEST PUMPS

FOR WARRANTY REGISTRATION CALL: 1-800-245-4777

Electric Models - Power source must meet voltage, phase, hertz and amperage

requirements of electric motor, as stated on label. If an extension cord is

used, requires at least 12 gauge 3 wire with maximum of 25 foot length.

2. Check all fluid levels prior to operating pump.

3.

Use a sound 3/4" or larger supply hose.

4. DO NOT run dry or pump chlorine through the unit.

5. Protect the pump from freezing, FLUSH with anti-freeze.

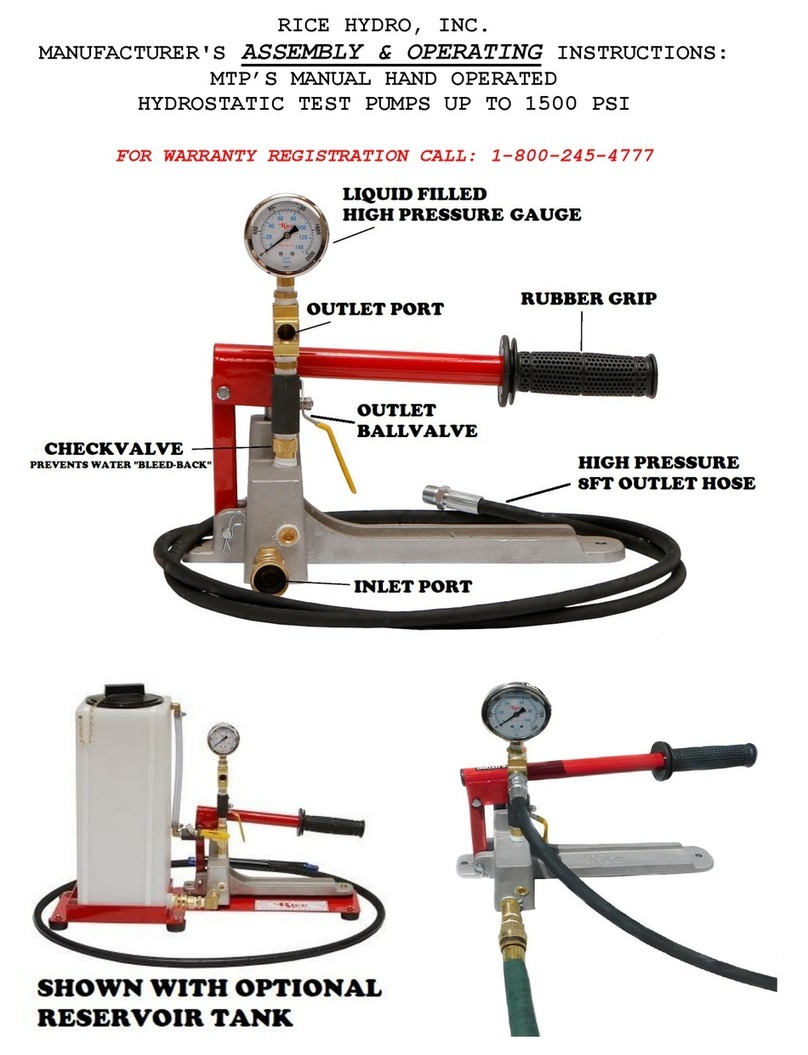

CONNECTING THE PUMP:

1.

Check oil level of engine as well as the oil level of pump thru sight glass, use

10W30 non-detergent as needed. Electric Models - With motor switch in the off

position, connect power cord of motor to a standard wall outlet. Extension

cord: when needed, requires a 12 gauge 3 wire, maximum 25 foot length plugged

into a 20 or larger amp breaker, depending on individual motor requirements.

Connect CLEAN pressurized water source (minimum 3/4") to the inlet of the pump.

It is recommended that the unit be pressure fed. For gravity feed locate water

within 8 feet and above level of unit, and then prime the pump.

Connect high pressure outlet hose to the pump and your test environment.

Turn the outlet ballvalve to the open position, begin water flow and start the

engine. The engine RPM is preset at the factory, DO NOT ADJUST!

The pressure regulator has been preset at the factory. To change this setting

you must make this adjustment while the water is flowing freely, and under NO

pressure. To adjust the pressure, first loosen the locknut. Turn the T-

handle/Knob clockwise to increase and counter-clockwise to decrease the

pressure. Place a ballvalve or similar open and close valve at the end of the

outlet hose, open and close this valve multiple times as needed, to check

pressure setting and re-adjust as necessary. It is also recommended that you

open and close the hosebib located under the gauge to bleed excess air from

piping and ensure accurate pressure gauge readings. Upon reaching desired

pressure setting, tighten locknut and prepare to begin test.

With the ballvalve open begin building pressure in the test environment. Be

sure to bleed the air from hosebib under gauge at least once during this

process. Once test pressure has been reached, close the ballvalve and shut-off

engine.

Once the outlet ballvalve is closed and your test begins, you have now isolated

the test pump from the test environment, any loss of pressure is due to leaks or

trapped air being compressed in the test environment.

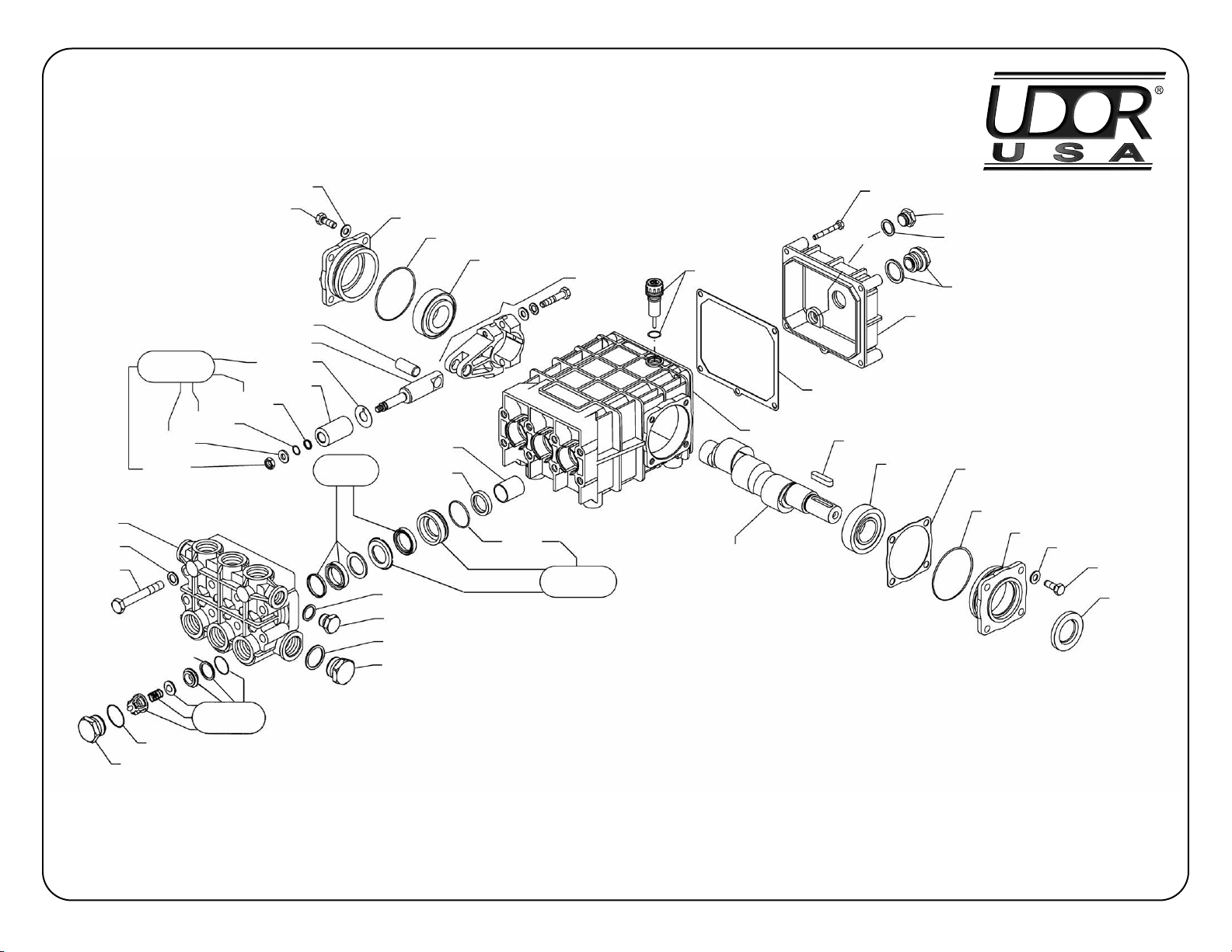

RECOMMENDED PERIODIC MAINTENANCE PROCEDURE

1.

Plunger pump - Change oil in the pump body after first 50 hours of use, and

every 250 hours thereafter. Change oil in the engine after first 5 hours of

use, and every 80 hours thereafter.

WARNING: Operating, servicing and maintaining this equipment can expose you to

chemicals including engine exhaust, carbon monoxide and lead, which are known to the

State of California to cause cancer and birth defects or other reproductive harm. To

minimize exposure, avoid breathing exhaust, do not idle the engine except as necessary,

operate and service your equipment in a well-ventilated area and wear gloves or wash

your hands frequently when servicing your equipment. For more information go to:

www.p65warnings.ca.gov