ENGLISH

Engine

7

THE CLASS AS WELL AS BEING REPRODUCED ON TWO COUPLING ELEMENTS IS ALSO

SHOWN ON THE TWO CRANKCASE HALVES OF THE CRANKCASE.

NOTE

CRANKCASE SPARE PARTS ARE ALWAYS CLASS X.

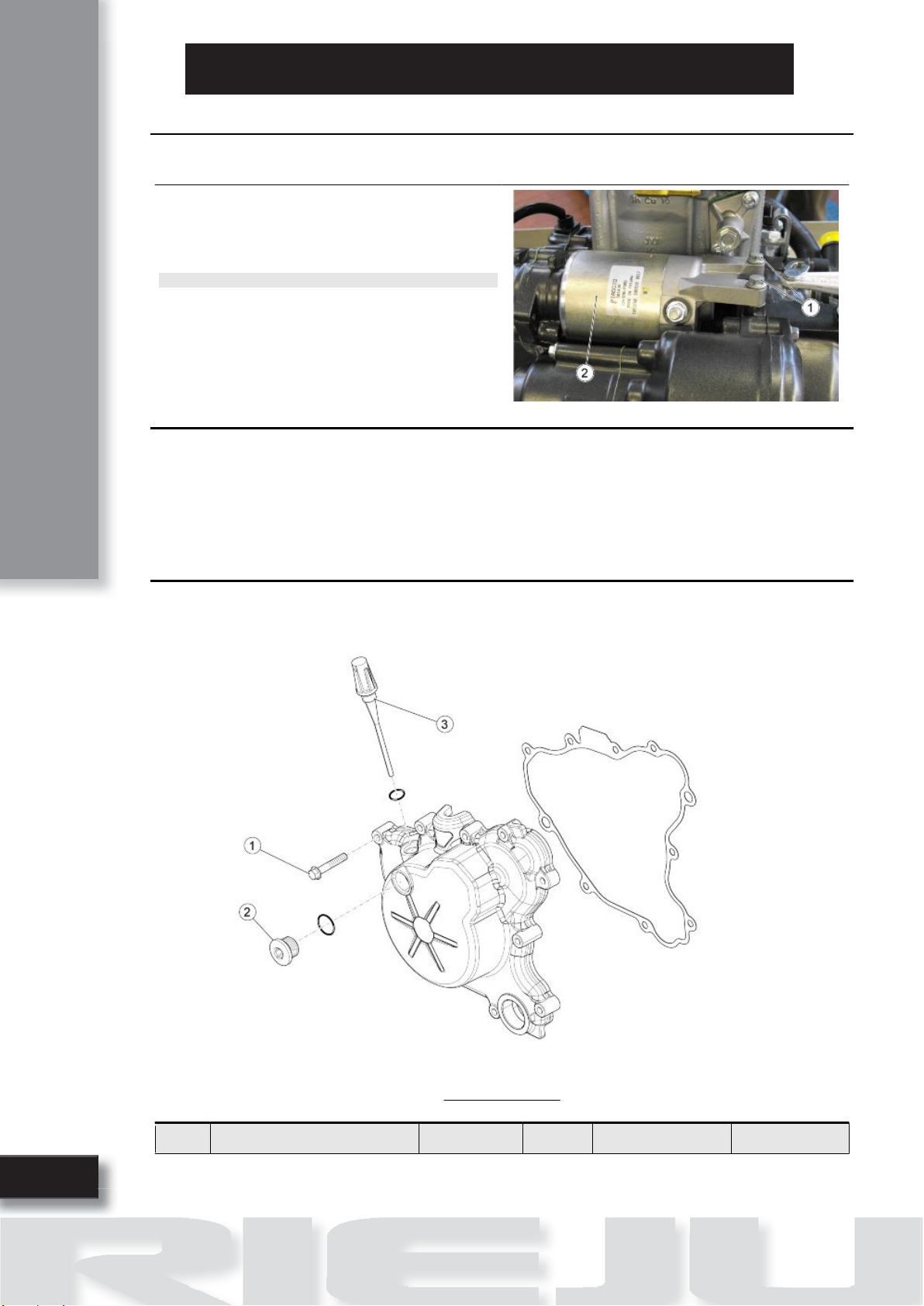

Checking the desmodromic drum

•Check the contact zone on fork (1) and the driving pin (2) of the forks for wear.

•Check the desmodromic drum (4) grooves (3) for wear.

•Make sure that both ball bearings rotate freely and check if there are signs of corrosion.

•Check the eccentricity of the transmis-

sion shafts.

•Check the condition of the two springs

(5) and (6) of the selector (7).

•Check the condition of the gears, re-

place them if they are blue, if they have

cracks or are worn.

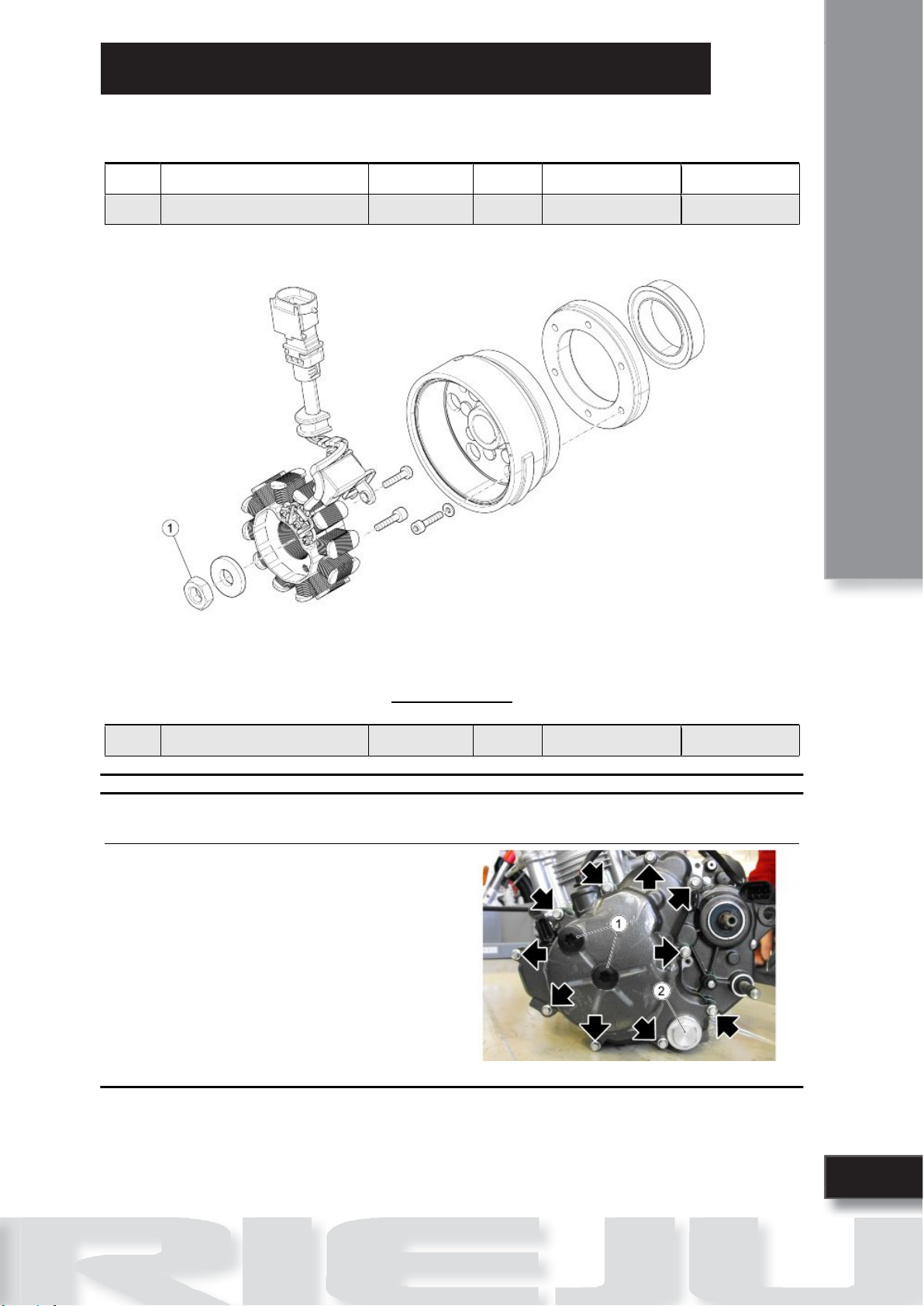

Assembling the gearbox

•Place the specific tool on the secon-

dary shaft to avoid damaging the oil

seal.

•Heat up the engine crankcase.

•Apply LOCTITE Anti-Seize on the

bearing seats present on the crank-

case.

•Fit the bearings in their seats.

•Insert the gears unit (5).

•Apply oil for gears on the grooves of the desmodromic drum.