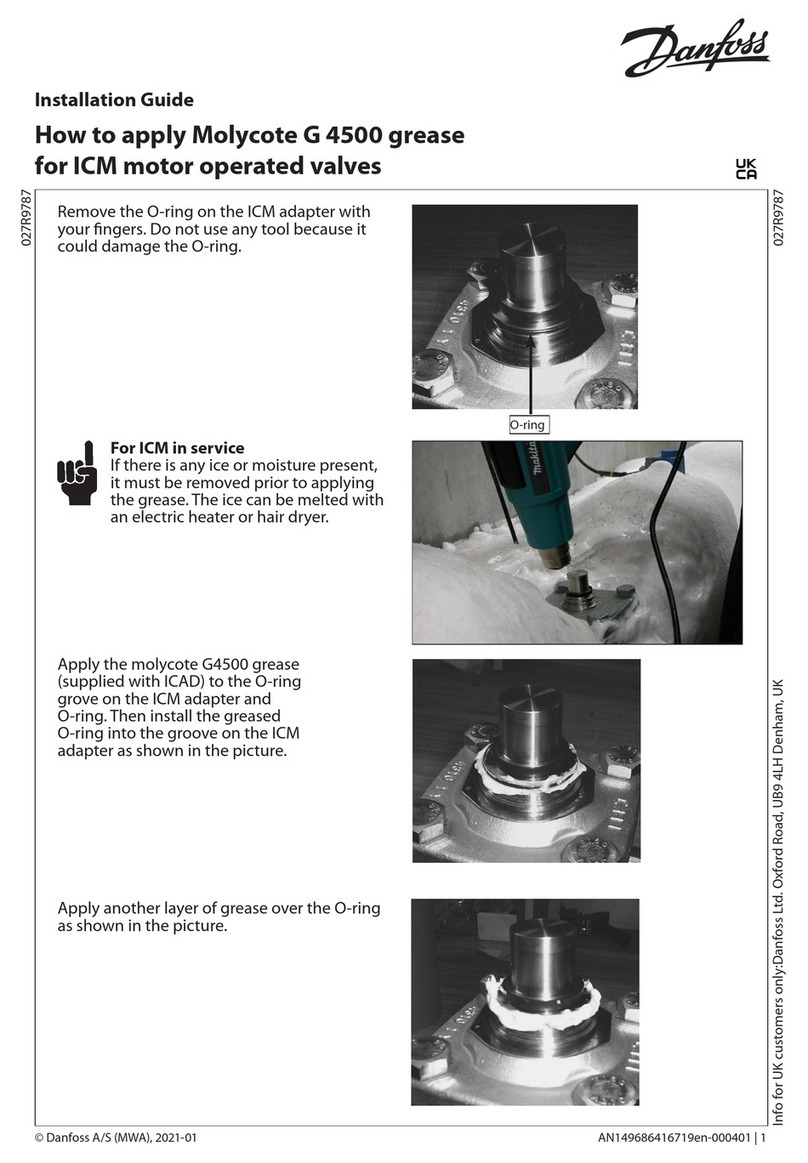

1. Fjern den monterede prop og skive på motoren (6 mm unbraco).

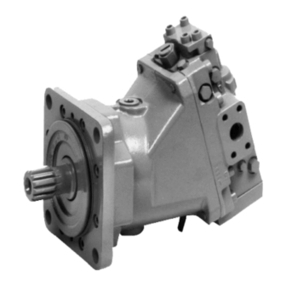

1. Remove the plug and washer from the motor (6 mm Allen

key).

1. Den Stopfen und Scheibe aus dem Motor entfernen (6 mm

Inbussschlüssel).

1. Ôter le bouchon et la rondelle du moteur (clé Allen à 6

cannelures).

2. Skru sensoren i, uden anvendelse af værktøj, til kontakt med

motorens aksel / møtrik.

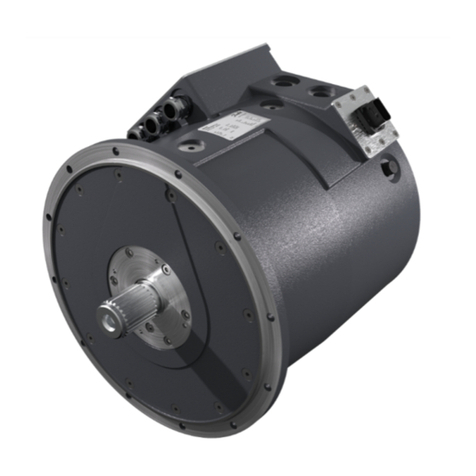

2. Without tools screw in the sensor till it makes contact with

the shaft/nut of the motor.

2. Den Drehzahlgeber ohne Anwendung von Werkzeug

einschrauben, bis Kontakt mit Welle/Mutter des Motors

erreicht wird.

2. Visser le capteur sans utiliser de l’outil jusqu’à ce qu’il y ait

contact avec l’axe/l’écrou du moteur.

3. Skru sensoren 1/4 omgang (90°) ud igen som vist på foto 3a.

3. Turn 1/4 revolution back again (90°) as shown on photo 3a.

3. Den Drehzahlgeber wieder 1/4 Umdrehung (90°)

ausschrauben. Siehe Photo 3a.

3. Dévisser le capteur d’un quart de tour (90°) comme indiqué

sur la photo 3a

4. Skru yderligere ud indtil de 2 gaffelflader (10 mm) er

oriente-ret i samme retning som motorens længdeakse.

Tolerance: ± 5°

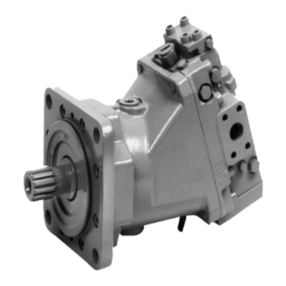

4. Turn further back until the 10 mm flats of the sensor are

aligned with th longitudinal axis of the motor. Tolerance ± 5°.

4. Weiter so ausschrauben, bis die zwei Gabelflächen am

Sensor identisch mit der Längsachse vom Motor orientiert

sind. Toleranz ± 5°.

4. Continuer à dévisser le capteur jusqu’à ce que les deux

plats à fourche (10 mm) soient orientés dans la même

direction que l’axe longitudinal du moteur. Tolérance : ± 5°

5. Hold sensoren i denne position, medens omløber spændes

med det foreskrevne tilspændingsmoment på 15 - 20 Nm.

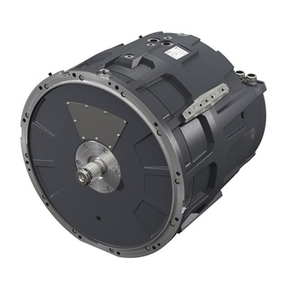

5. Keep the sensor in this position while tightening the

compression nut to the prescribed torque of 15-20 Nm.

5. Den Drehzahlgeber in dieser Stellung halten während die

Überwurfmutter zum vorgeschriebenen Anzugsmoment

von 15-20 Nm angezogen wird.

5. Maintenir le capteur dans cette position et serrer l’écrou en

appliquant le couple prescrit de 15 – 20 Nm.

1 2

33a

4 5

For at sikre sensorens funktionsevne, er det nødvendigt at

trin 2 til 5 er udført korrekt og i den rigtige rækkefølge.

To make the sensor work, be sure to carry out the steps 2 – 5

correctly and in the right order of succession.

Um die korrekte Funktion vom Drehzahlgeber zu sichern,

müssen die Anweisungen 2 bis 5 genau und in der richtigen

Reihenfolge beobachtet werden.

Le bon fonctionnement du capteur est garanti par l’exécution

correcte, et dans le bon ordre, des phases de montage 2 à 5.

90°