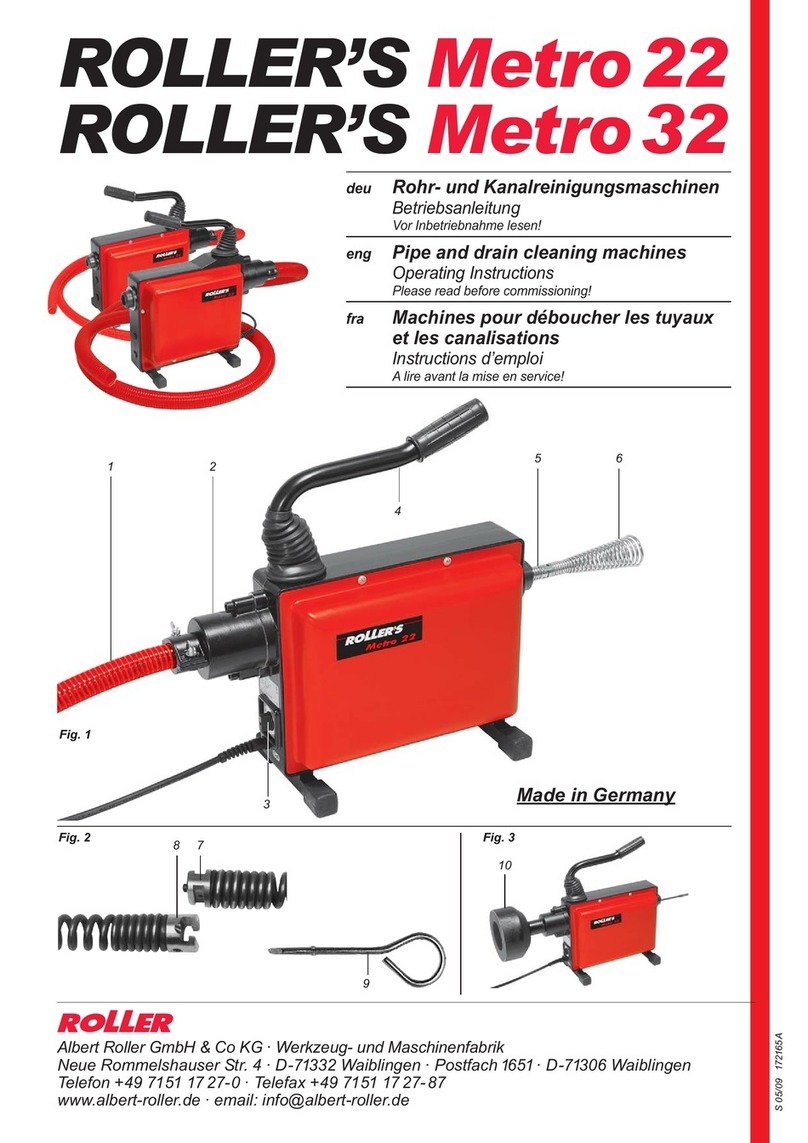

Rioned Allround+ User manual

User’s Manual

Allround+

Edition: 05.1

Date: Saturday 11 November 2017

RIONED

P.O. Box 5070

5004 EB Tilburg

The Netherlands

Telephone: +31 13 5479100

e-mail: [email protected]

Internet: www.rioned.com

11/17 2

©Copyright 11/17 Rioned/RIOR B.V.Tilburg- Nederland.

All rights reserved. No part of this publication may be copied or published by means

of printing, photocopying, microfilm or otherwise without the prior written consent of

RIONED. This restriction also holds for the corresponding drawings and diagrams.

RIONED has the right to change parts of the machine at any time without any prior

or direct warning to the client. Similarly, the contents of this manual can also be

changed without any prior warning.

This manual is to be used only for this machine.

For extra information on adjustments, maintenance and repair, contact the technical

department of your dealer.

11/17 3

Foreword

This user’s manual is a manual for the professional user.

This user’s manual has the purpose to control the machine in a safety manner and

must be saved with the machine.

The photos and drawings help you understand the text easier.

First the user’s manual gives you an overview of the most important safety aspects.

Then we explain how the machine is built up and the global working of the machine.

Chapter “Technical specifications” gives you information about the working character-

istics, performance under normal use and construction specifications.

“Control” is the next chapter. This chapter explains how to use the machine system-

atically.

In the chapter “Maintenance”, the user can do small maintenance on the machine.

Chapter “Trouble shooting” has the purpose to solve simple defects.

With the “Exploded views” you can order original spare parts, are also useful for

mounting, and disassemble the machine.

Finally gives the chapter “Appendix” information about electrical and/or hydraulic

connections.

11/17 4

11/17 5

Table of Contents

1 Introduction...............................................................................7

1.1 Use......................................................................................7

2 Security......................................................................................9

2.1 Instruction indications in this manual........................................9

2.2 Descriptions security measures................................................9

2.3 Personnel protection outfit ......................................................9

2.4 Warnings..............................................................................9

2.5 Personnel qualification and education .....................................10

2.6 Danger that can occur if the security regulations aren’t observed10

2.7 Working safely.....................................................................10

2.8 Security regulations for the user and technical service ..............10

2.9 Security regulations for maintenance, inspection and mounting ac-

tivities................................................................................10

2.10 Making changes and fabricate spare parts ...............................10

2.11 Improper use ......................................................................10

3 Technical Specifications ...........................................................13

3.1 General .............................................................................13

3.2 Motor 230V ........................................................................14

3.3 Motor 110V ........................................................................14

4 Construction.............................................................................15

5 Control .....................................................................................17

5.1 Transport............................................................................17

5.2 Controls..............................................................................18

5.3 Lade verwijderen .................................................................20

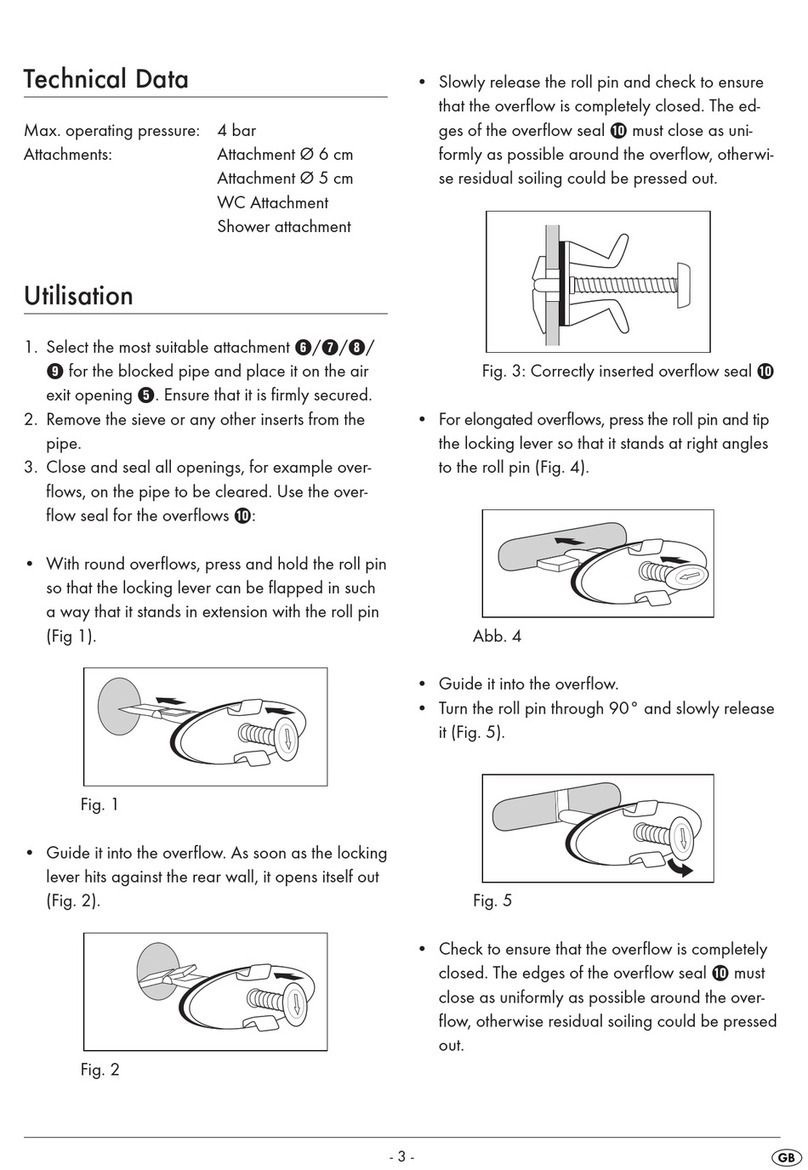

5.4 Before unblocking ................................................................21

5.5 Unblocking..........................................................................24

6 Options.....................................................................................27

6.1 Foot switch .........................................................................27

7 Maintenance.............................................................................29

7.1 General ..............................................................................29

7.2 Cleaning the feed unit ..........................................................29

7.3 Lubrication..........................................................................33

7.4 Extensive periodical maintenance...........................................33

7.5 Maintenance schedule...........................................................34

8 Accessories ..............................................................................35

8.1 Supplies .............................................................................35

8.2 Auxiliaries that can be coupled: .............................................36

9 Exploded View

Explosionszeichnung und Ersatzteilliste

Dessin et Liste de Rechange.............................................................39

11/17 6

9.1 Exploded view .....................................................................40

9.2 Stuklijst..............................................................................41

9.3 Part list ..............................................................................42

9.4 Ersatzteilliste.......................................................................43

9.5 Liste de rechange.................................................................44

10 Appendix ..................................................................................45

10.1 EC declaration Of Conformity For Machinery ............................45

10.2 Sales Managers ...................................................................46

10.3 Dimensions.........................................................................47

10.4 Geluidsmeetrapport..............................................................48

10.5 Wiring diagram....................................................................49

10.6 Safety instructions ...............................................................50

11 Index .......................................................................................53

11/17 7

1 Introduction

RIONED wishes to thank you for your purchase of the RIONED drain and sewer-

clearing machine. We recommend that you read this manual thoroughly and

see that the machine is handled and maintained in the proper manner. If your

machine should give trouble and need servicing, when you want to order parts,

or if you have any questions, contact your RIONED dealer.

The machine is built by:

RIONED

P.O. Box 5070

5004 EB Tilburg

The Netherlands

Telephone: +31 13 5479100

e-mail: [email protected]

Internet: www.rioned.com

Your machine is specifically designed to clean drain- and sewer pipes with a di-

ameter from 40 mm to 125 mm by using specially manufactured cleaning

springs with a diameter of 16 mm diameter.

The machine may only be used by authorized personnel.

The machine can not be used in an explosive environment.

Fill the spring drum only with springs we describe in this manual.

In this manual you will find all necessary information concerning operations and

maintaining your machine. If handled properly, your machine is guaranteed ac-

cording the general delivery conditions.

1.1 Use

The main shaft is being driven by the electrical motor by means of chainwheel.

On this axle the spring drum is mounted. The drum contains the spring which

is to be lead into the drain or sewer opening. By means of the spring transport-

er and rotation direction the spring can be:

A Fed out of the drum.

B Fed into the drum.

C Kept in place.

11/17 8

11/17 9

2 Security

Be responsible for other people when you are working with this machine.

This manual contains instructions for fundamental conditions that must be fol-

lowed by use and maintenance of this machine.

That is why it is necessary that authorised and qualified personnel must read

the user's manual and the user’s manual must always be available with the ma-

chine. Near the general regulations in this chapter, you must also follow the se-

curity regulations in the other chapters.

2.1 Instruction indications in this manual

The in this manual containing security instructions, which are dangerous if they

are not obeyed, are marked with general security signs.

Security sign DIN 4844-W9

2.2 Descriptions security measures

•Stop

This machine is equipped with an stop. By operating the emergency

stop, the machine will stop. Also use it when dangerous situations oc-

cur. After use, remove the danger. Make sure the stop can always be

reached.

• Security covers

This machine is equipped with several security covers over parts that

are rotating. It is forbidden to remove these security covers during op-

erating this machine. You can only remove them if there is mainte-

nance on the machine. Stop the machine and take the plug out of the

wall socket.

• Spring guidance tube

The spring guidance tube protects you against the rotating spring. Now

your clothes can not get clamped between the spring openings.

2.3 Personnel protection outfit

• Protection looking glasses

•Gloves(Recommended)

• Dust cover (Recommended)

2.4 Warnings

Never take the spring when turning.

Do not let the spring turn outside ( swing of the spring).

11/17 10

Do not start the machine with switched in feed unit.

Take care of a stable disposition of the machine.

Never block the control lever, unless this is mentioned.

Do not wear cloth that hangs loose.

Please note safety instructions (See Chapter 9.5 "Safety instructions" page:

35).

Dust that arises when working on material containing asbestos or stonework

containing crystalline silicic acid is harmful to the health. Please follow accident

prevention regulations.

Do not pierce the motor housing as this could damage the double insulation

(use adhesives).

Keep mains lead clear from working range of the machine. Always lead the ca-

ble away behind you.

Never touch the spring if it is rotating. Not even with auxiliaries or other tools.

Never let the spring rotate outside a sewer, drain or pipe.

Never start the machine with the spring pusher downwards.

Never touch the spring if it is rotating. Not even with auxiliaries or other tools.

Never let the spring rotate outside a sewer, drain or pipe.

Make sure the machine is stable during operation.

Do not let the machine operate without supervision.

2.5 Personnel qualification and education

Personnel that use, maintain and inspect the machine must have the right qual-

ifications for this job.

Responsibility and authorisation of the personnel and the supervision on the

personnel must be embedded. If the knowledge is not present, the user must

provide for the necessarily education.

2.6 Danger that can occur if the security regulations aren’t observed

If the security regulations are not observed, danger can occur for personnel

and for the environment.

No amends are given if the regulations are not observed.

If the regulations are not observed, this can results in:

• Failure of important functions of the machine.

• Failure of prescribes methods for maintenance.

• Exposure of persons to dangers of electrical or mechanical failures

2.7 Working safely

The in this manual named security prescriptions, the national prescriptions to

11/17 11

prevent accidents and the internal labour, company and security prescriptions

must be followed by the user.

2.8 Security regulations for the user and technical service

• Protections of moving parts (for example couplings) may not be re-

moved if the machine is working.

• Leakage of dangerous mediums must disposed in a manner that there

is no danger for the personnel and environment. Statutory regulations

must be followed.

• Danger caused by electricity must be excluded.

2.9 Security regulations for maintenance, inspection and mounting activities

• The user sees to it that qualified technicians do all maintenance, in-

spection and mounting activities. They must study the manual thor-

oughly.

• Maintenance may only be done when the machine is not functioning

and the plug is out of the wall socket.

• The in the user’s manual mentioned handling to stop the machine must

be notified.

• Directly after maintenance of the machine, all the security and protec-

tion facilities must be functionally.

• Before starting the machine again, you must follow the instructions

correctly.

2.10 Making changes and fabricate spare parts

Changes to the machine are only permitted if Rioned has given written author-

isation. The use of original spare parts and accessories are for the safety nec-

essary. Rioned is not responsible for injuries or damages if other spare parts

are used.

2.11 Improper use

The security during working with the machine is only guaranteed if the use of

the machine is conform the user’s manual. The limits that are written in chapter

“Technical Specifications” and “Appendix” may never be overstept.

If the machine does not work or give troubles, it is forbidden to work further

with the machine. Telephone your dealer or the technical department of Rioned

Telephone: +31 (0) 13-5479100

This manual contains all the necessary information concerning control and

maintenance. If the device is positioned correctly, properly controlled, and reg-

ularly maintained, a warranty will be given according to the general conditions

of delivery. However, should it arise that the control and maintenance proce-

dures are not diligently followed, the warranty will become invalid.

11/17 12

11/17 13

3 Technical Specifications

3.1 General

Description (symbol) Unit

Type : Allround+

Dimensions : see chapter 10.3 Dimensions page.: 47

Weight (dry) (m) : 23,5 kg

Spring lengths (l) : 5 m, 10 m, 15 m and 20 m

Maximum spring length : 30 m

Spring diameter : 13 mm - 16 mm

Springs suitable for sewer diameter : 40 - 125

Place type plate:

Place frame number:

In and out speed spring : 0 - 8 m/min

Rotation direction : Left and right

RPM drum : 195 r.p.m.

Year of construction (month/year) :Seetypeplate

J

11/17 14

3.2 Motor 230V

Description (symbol) Unit

Mark/Type : Neri

Power (P) : 250 W

Revolutions : 1450 r.p.m.

Voltage and frequency : 230 V, 50 Hz.

Security : Thermal

Cos :0,94

Isolation class : IP 54

3.3 Motor 110V

Description (symbol) Unit

Mark/Type : Neri

Power (P) : 250 W

Revolutions : 1660 r.p.m.

Voltage and frequency : 110 V, 60 Hz.

Security : Thermal

Cos :0,94

Isolation class : IP 55

11/17 16

11/17 17

5Control

If you control, maintain or inspect the machine, you must have

the right qualifications for this job. If you do not have the

necessarily knowledge, you may not use the machine. Further,

you must convince yourself that you understand this manual

thoroughly.

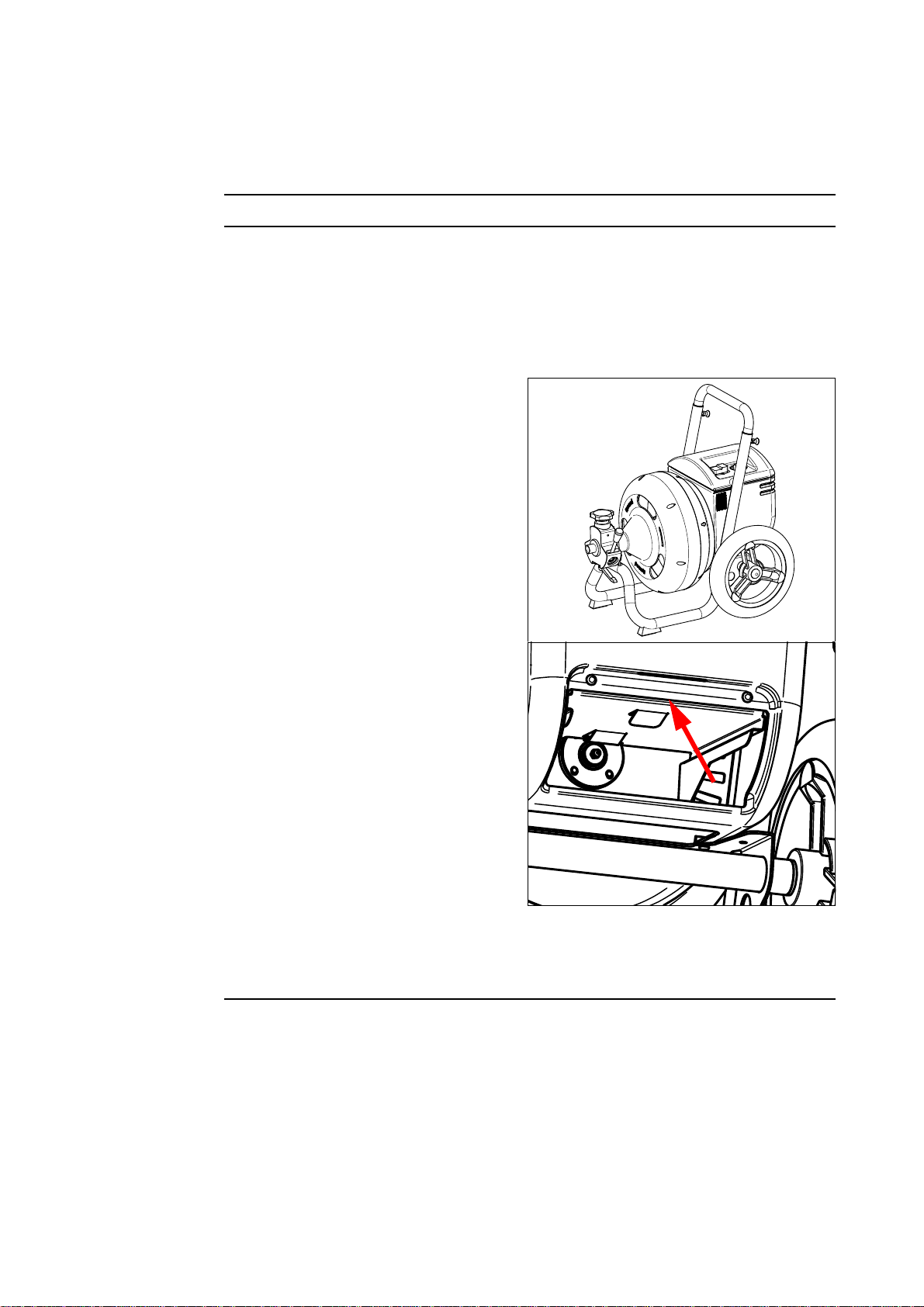

5.1 Transport

1. Pull the plug out of the wall socket.

2. Wind the wire around the bow.

3. Couple the extra spring loose and put in storage.

4. Transport the standard spring in the drum.

5. Let the standard spring reach a little bit out of the feed unit.

6. Pull the knobs of the bow

loose (2x).

7. Pull the bow completely out

of the frame.

8. Lock the bow again.

9. Overturn the spring machine

by means of the bow.

10. Now you can move the spring

machine.

11/17 18

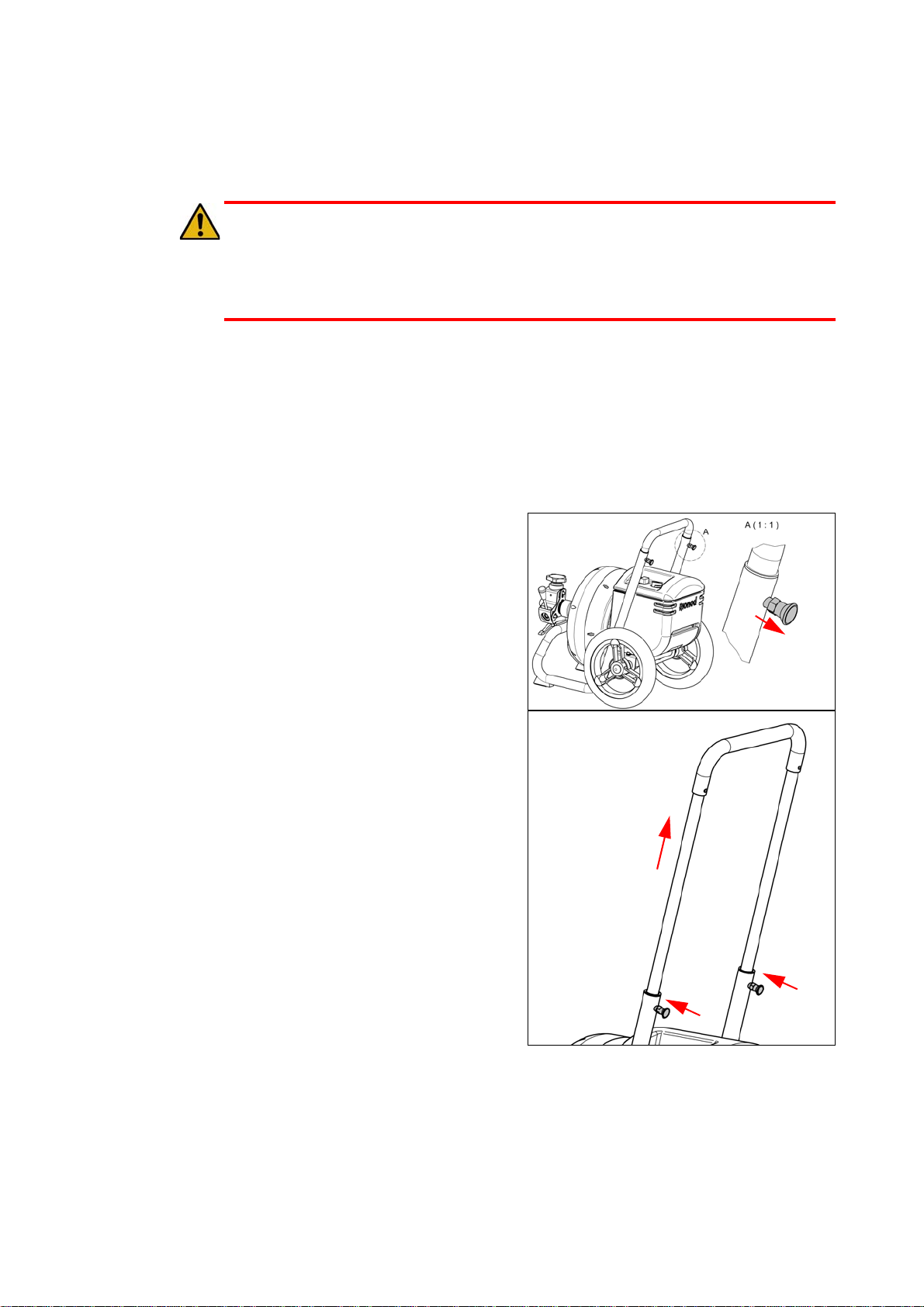

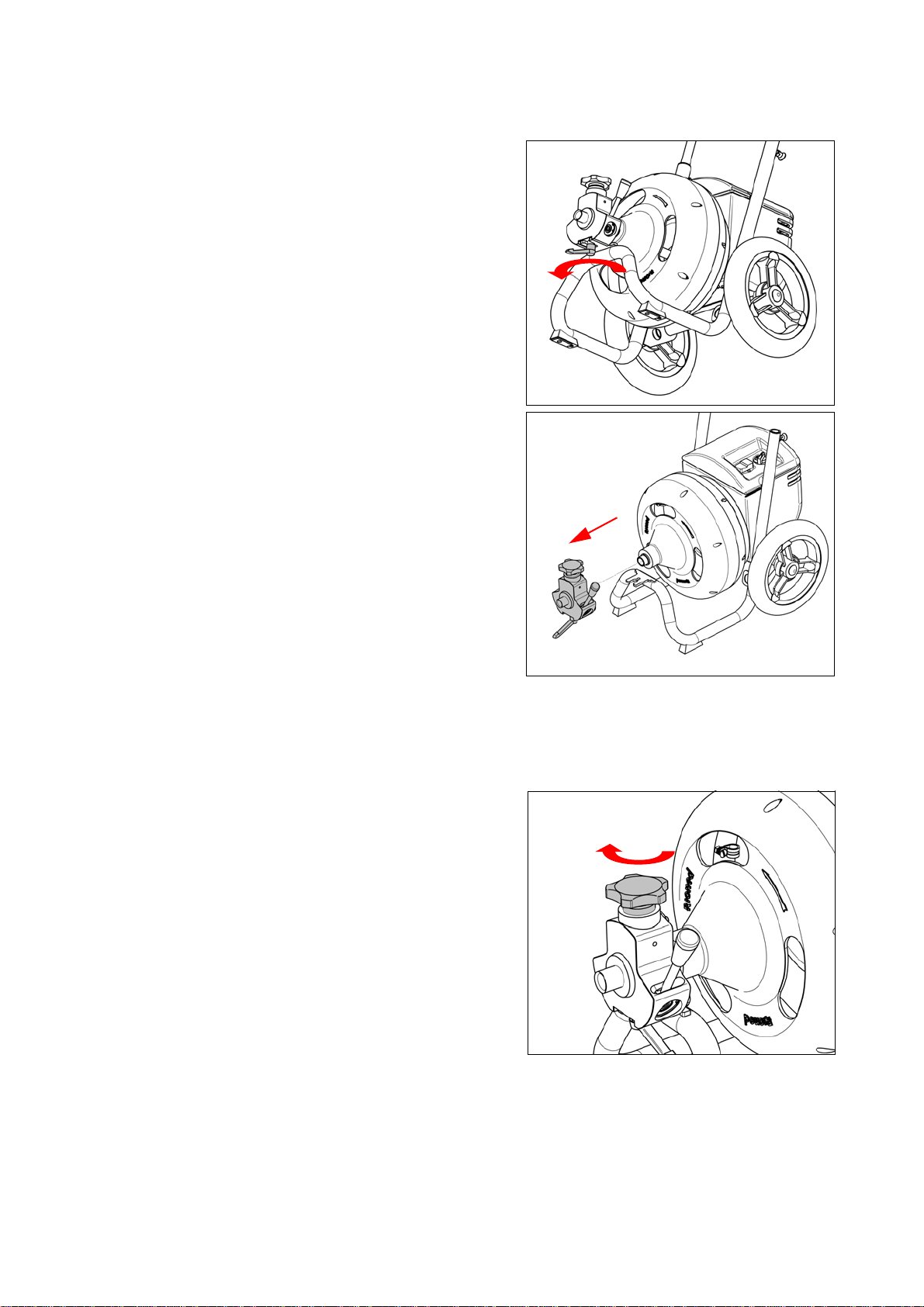

5.2 Controls

1. Clamp handle:

Turn the handle a quarter

turn loose to dismount the

feed unit.

2. Pressure knob:

By turning the pressure knob, you can bring the feed unit in and out

of order.

a Turn pressure knob

clockwise:

Feed unit activated.

Spring rotates and gets

transported.

11/17 19

b Turn pressure knob

counter clockwise:

Feed unit out of order.

Spring rotates, no

transportation.

3. Switch:

Position : no rotation.

Position : drum rotates in

working direction.

Position : drum rotates

reverse. First push the plate

lock (A), then turn the switch

further over the plate. Use

this position to get a jammed

spring back.

4. Press button “Green”:

With this button, the motor

starts. The drum begins to

rotate in the chosen direc-

tion.

5. Press button “Red”:

By operating the stop, the

machine will stop. Also use it

when dangerous situations

occur.

Make sure the stop can al-

ways be reached.

A

11/17 20

6. Feed unit handle:

By operating this handle, the

transportation ofthe spring is

controlled.

a Lever maximum point-

ing to the drum:

Spring transport speed

maximum in.

b Lever maximum from

the drum off:

Spring transport speed

maximum out.

c Lever in the middle:

no transport.

7. Drawer with accessories

5.3 Lade verwijderen

1. Lade open schuiven

2. Lip indrukken

3. Lade uitnemen

Table of contents