RISCHE + HERFURTH POLYSTAR 120 GE User manual

120 GE

- Translation of the original instruction manual -

Last revised 04/2014

polystar® impulse generator 120 GE with model 300 D welding tongs

polystar® model SFZ welding tongs polystar® model DS welding tongs

120

GE

- Translation of the original instruction manual -

Page 2 of 15

Table of contents

1. Figures ......................................................................................................................3

1.1. Important safety instructions .....................................................................................4

1.2. Correct use ...............................................................................................................5

2. General information...................................................................................................5

2.1. Data for the polystar® impulse generator..................................................................5

2.2. Use............................................................................................................................6

2.3. Start-up and operation ..............................................................................................6

2.3.1. Practical tips..............................................................................................................7

2.3.2. Replacing the polystar® welding tongs .....................................................................7

2.3.3. Adjustable contact pressure of the polystar® welding tongs .....................................7

3. Fault detection and troubleshooting ..........................................................................8

4. Maintenance .............................................................................................................8

4.1. Replacing the heater elements..................................................................................9

5. Emissions................................................................................................................10

6. Transport.................................................................................................................10

7. Disposal ..................................................................................................................10

7.1. ... in Germany..........................................................................................................10

7.2. ... in other EU countries...........................................................................................10

8. Spare parts list ........................................................................................................11

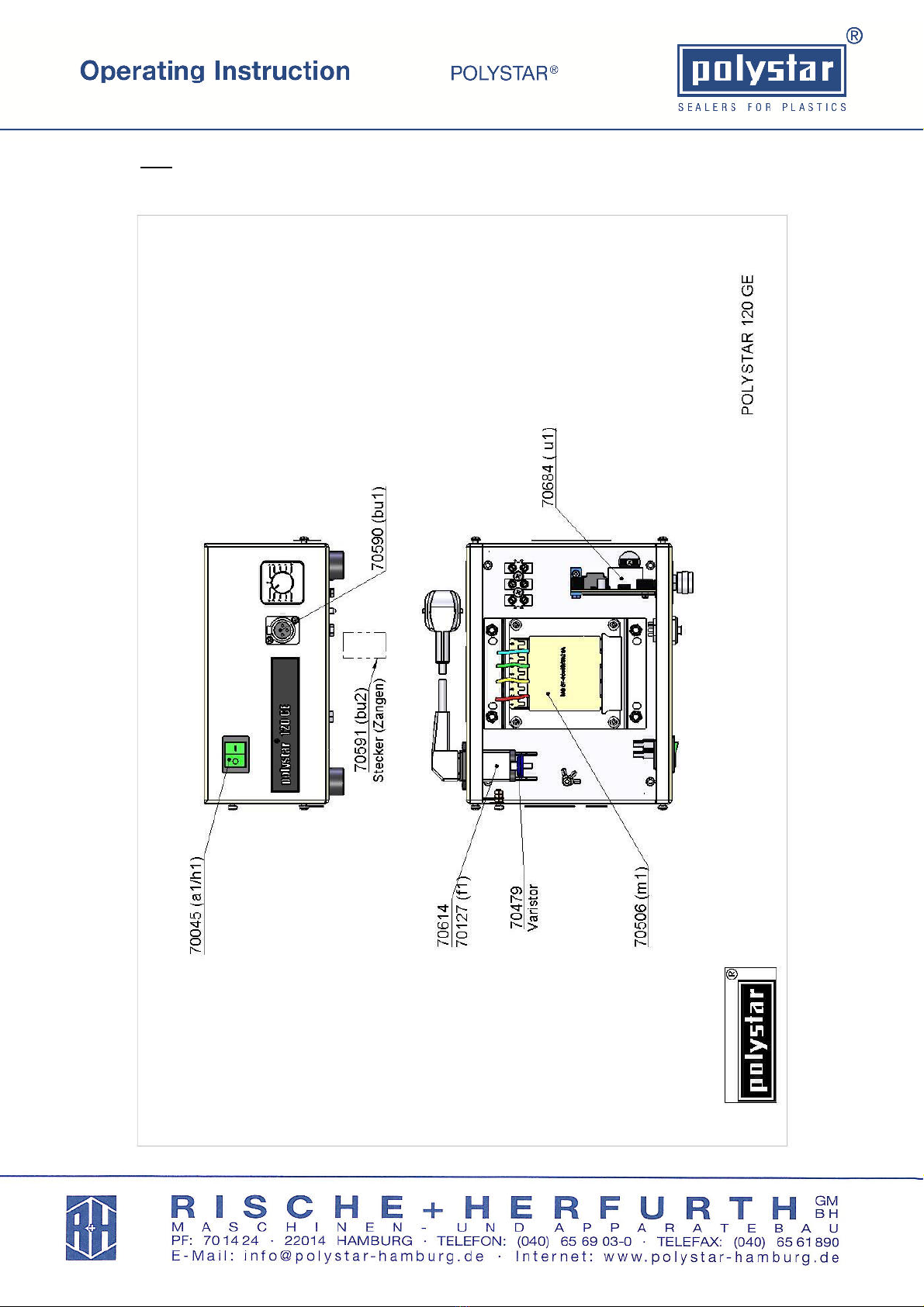

9. Key..........................................................................................................................13

10. Circuit diagram........................................................................................................14

11. EC Declaration of Conformity..................................................................................15

120

GE

- Translation of the original instruction manual -

Page 3 of 15

3

1. Figures

1

Rocker switch, green (On/Off switch)

2

Metal knob (setting for the length of the thermal impulse)

3

Connector for welding tongs

3 a

Locking key for output socket

4

Adjusting device for contact pressure

5

Green push-button (triggers the thermal impulse)

6

Green LED (shows the thermal impulse)

7

Strip-heater carrier with heater elements

7

6

5

3 a

2

1

4

120

GE

- Translation of the original instruction manual -

Page 4 of 15

2. Important safety instructions

•Read the operating instructions carefully before starting work with the polystar® impulse

generator.

•Pay attention to the safety instructions.

•Make sure that the mains voltage is the same as the device voltage before connecting the

polystar® impulse generator.

•The device voltage can be found on the rating plate on the rear of the device.

•Do not reach in between the strip-heater carrier (jaw).

•Do not place the mains plug in water or any other liquids.

•Do not bend the mains lead or place this on hot surfaces.

•Following intense use of the impulse generator certain surfaces, particularly the strip-heater

carrier, may be hot as a result of the process. This also holds true after the impulse generator

has been switched off.

•Do not leave the polystar® impulse generator unattended when switched on.

•Switch the polystar® impulse generator off during longer interruptions to use.

•Do not place any combustible items on the polystar® impulse generator or welding tongs.

•Repairs may only be carried out by qualified personnel.

•All warranty claims and the product liability will be forfeited with an incorrect use of the device.

•Disconnect the mains plug before all maintenance, repair or cleaning work.

•The mains plug is a mains isolating link and must be able to be checked directly by the

operating personnel during work on and with the impulse generator. Ensure unhindered access

at all times.

•Non-ionising radiation is not specifically generated but is only emitted technically by the

electrical equipment (e.g. by transformers). Furthermore, the device has no strong permanent

magnets. If you observe a safety gap of 30 cm (distance between the field source and implant)

any negative effects on active implants (e.g. pacemaker, defibrillators) can very likely be ruled

out.

•The polystar® impulse generator is not explosion-proof and does not fall under any IP

protection class.

120

GE

- Translation of the original instruction manual -

Page 5 of 15

3. Correct use

This product is a piece of technical equipment. It may only be used at work.

Only ever use films (packaging) that do not release any hazardous emission during sealing.

Only ever use films (packaging) that do not react critically with the sealed products.

Only ever use the polystar® impulse generator in dry areas.

Do not use in wet, dusty or potentially explosive areas.

The polystar® impulse generator is only suitable for sealing thermoplastic films or other PE-

coated materials.

Only ever trigger thermal impulses when the film to be sealed is on/between the heater

element(s).

Do not place any other materials or objects between the heater elements.

Use only a damp cloth or air jet cleaner to clean the outside of the polystar® impulse

generator.

4. General information

This portable film sealer consists of the polystar® impulse generator 120 GE and welding tongs.

This film sealer works according to the thermal impulse principle and is ready for immediate use

without heating up.

Each welding tongs is equipped with two strip-heater carriers (jaws) that contain the heater

elements.

4.1. Data for the polystar® impulse generator

Description:

polystar®

impulse generator 120 GE

Manufacturer: RISCHE + HERFURTH GMBH, Hamburg

Power supply: 230 V / 50 Hz

Current drain: approx. 1.9 A / 3.7 A

Current consumption: approx. 430 W / 860 W

Welding tongs: Working width 150 - 300 mm: 21 V

Working width 400 - 600 mm: 42 V

Impulse generator dimensions: approx. 246 x 195 x 135 mm Weight: approx. 6.8 kg

Welding tongs dimensions: approx. 160, 210, 310, 410, 610 x 200 x

65 mm

Weight: approx. 0.7 –

1 kg

120

GE

- Translation of the original instruction manual -

Page 6 of 15

4.2. Use

This polystar® impulse generator 120 GE in combination with the polystar® welding tongs can be

used to safely seal all standard thermoplastic films (e.g. polyethylene) as well as composite films in

a tube and bag shape.

Max. PE film thickness: 2 x 0.30 mm

Seal width: 3 mm

Seal length (depending on tongs): 150 mm

200 mm

300 mm

400 mm

600 mm

4.3. Start-up and operation

Position the polystar® impulse generator with the welding tongs so as to allow ergonomic

working. Furthermore, the stability of the impulse generator must be guaranteed at all times.

Plug the connector for the welding tongs into the output socket on the front of the impulse

generator. The connector must be heard to lock into place.

Plug the impulse generator's mains plug into the wall socket.

Switch the rocker switch (green) on the front of the device on.

Turn the metal knob to position "1" on the scale. The sealing time is infinitely variable.

Take the welding tongs in your hand. Press the handles together to open the strip-heater carrier.

Place the film to be sealed between the strip-heater carriers (jaws) and close the tongs. To trigger

the sealing impulse, press the green push button on the upper handle of the welding tongs with

your thumb. The green LED comes on. Keep the push button pressed until the green LED goes

out.

The sealing impulse ends when the green LED goes out. The cooling phase begins immediately

after this, during which the film material must be left to cool down under pressure. The welding

tongs should not be opened beforehand.

The cooling phase should be counted in seconds by the user and should be at least 3 seconds.

The sealing process is completed at the end of the cooling phase.

Now open the welding tongs and remove the sealed film material.

If no satisfactory result is found when checking the seam, turn the metal knob for the sealing time

one setting higher. You may have to repeat the procedure several times.

Note: in order to achieve a good seam, do not set the sealing time higher than is

necessary. Even though a higher setting can also produce good results it places too

much load on the heater element. This in turns leads to premature wear.

120

GE

- Translation of the original instruction manual -

Page 7 of 15

4.3.1. Practical tips

Reduce the thermal impulse for more than ten consecutive seals (continuous operation). This

reduces the residual heat that accumulates in the heater elements and minimizes wear.

Use films with the specified sealing seam length wherever possible. If narrower films are used,

perform the sealing on alternate sides (right, left, center). This spreads the load over the heater

elements.

You can prolong the service life of the heater elements by lightly lubricating the Teflon coating at

regular intervals. Our polystar® silicone paste is available under the order no. 111 300.

Note:

If the device is used regularly the Teflon coating should be lubricated once a week in the evenings

so that the silicone paste can soak in over night. A thin film of silicone is sufficient.

4.3.2. Replacing the polystar® welding tongs

The three-pole connector is secured in the output socket by a catch. This lock has to be released

on the right side of the output socket when replacing the welding tongs. Press the locking key in

and pull the connector out of the impulse generator at the same time.

4.3.3. Adjustable contact pressure of the polystar® welding tongs

The contact pressure of polystar® welding tongs can be adjusted to different film thicknesses and

materials. A corresponding adjustment device has been integrated in the lower handle of the tongs.

You can easily adjust the contact pressure to your individual requirements with a size 5 Allan key.

Turn to the right to increase the contact pressure and to the left to reduce this.

The contact pressure has been set to an average film thickness in the factory. An optimum contact

pressure alongside the correct sealing and cooling times is absolutely necessary in order to

achieve a good seam. Changing the contact pressure always affects the quality of the seam.

120

GE

- Translation of the original instruction manual -

Page 8 of 15

5. Fault detection and troubleshooting

In case you do not press the green button enough in accordance with the pre-selected

Heat impulse, you will hear an acoustic error signal. Please check and repeat the welding process.

Unplug the device from the mains before opening!

If the polystar® film sealer no longer seals bags, check the mains socket.

A qualified person should also check the fine-wire fuse in the power outlet. The housing does not

have to be opened for this.

Damage to the Teflon coating (holes, dark discolorations) is a sign that the strip-heater has burnt

out. Change the heater elements if this is the case (see assembly instructions on page 9)

Please note that wear parts (heater element, strip-heater, Teflon tape) are excluded from the

warranty.

All other faults have to be located and remedied in a service center. You can also send us the

polystar® impulse generator together with the welding tongs for repair.

6. Maintenance

Heater elements may only be replaced by qualified persons. Observe the following assembly

instructions to the word.

We use Teflon tape for the heater elements on account of its high temperature stability. It also

stops the film from sticking.

If the strip-heater has burnt out, the complete heater element has to be replaced.

120

GE

- Translation of the original instruction manual -

Page 9 of 15

6.1. Replacing the heater elements

You will need the following tools to replace the heater elements:

flat nose pliers, Philips screwdriver, slotted screwdriver.

Step 1:

Loosen the four Philips screws

on the strip-heater carrier (jaw)

screen.

Step 2:

Remove the strip-heater carrier

screen.

Step 3:

Loosen the outer screws of the

terminal plug and pull out the

ends of the strip-heater.

Step 4:

Take a new heater element.

Thread the end of the strip-

heater through the terminal

plug.

Step 5:

Tension the terminal plug by

pressing it against the strip-

heater tension spring. Tighten

the screw of the terminal plug.

Step 6:

Repeat the procedure for the

other end of the strip-heater.

Then pull the end of the strip-

heater through the terminal

plug with the flat nose pliers

and pull tight.

Step 7:

Bend over the protruding ends

of the strip-heater so that they

do not make contact with any

metal (accidental ground!).

Pay attention to the proper fit of

the terminal plugs (tensioned)!

Step 8:

Then retighten the strip-heater

carrier screen.

Repeat this procedure with the

other strip-heater carrier if

necessary.

Note: The terminal plugs must exert a slight tension on the strip-heater to compensate the

elongation of the strip-heater through the thermal impulse.

120

GE

- Translation of the original instruction manual -

Page 10 of 15

7. Emissions

polystar® film sealers are almost silent when in operation. The workplace noise is below

70 dB(A).

Gases and vapors, e.g. sealing fumes, are not produced if the device is operated correctly and

when sealing thermoplastic films and PE-coated composite films.

8. Transport

The polystar® impulse generator 120 GE should be transported by the handles provided for this

purpose.

The polystar® welding tongs can be transported by their handles.

9. Disposal

9.1. ... in Germany

In accordance with the German Electrical and Electronic Equipment Act (ElektroG),

all used electrical and electronic equipment that is put on the market has to be

disposed of correctly. The device can be disposed of at the local waste recycling

center.

WEEE Reg.No.: DE 48588228 (ElektroG)

In accordance with the German Packaging Ordinance (5th amendment of the

VerpackV), the transport packaging is licensed by our company in Germany. Please

dispose of the delivered packaging correctly in the corresponding resource recovery

cycles.

9.2. ... in other EU countries

Please observe the laws and regulations applicable in your country.

120

GE

- Translation of the original instruction manual -

Page 11 of 15

10. Spare parts list

polystar® impulse generator 120 GE

Order number Item

20365 A Chassis

20366B Hood

70614 Power outlet, with interference filter and fuse

70127 Fuse 6.3A/250V/5x20, semi time-lag

(f1)

70566 PE insulating bush

70567 Flat plug bush

70568 Flat plug

70651 Fitted power outlet mains lead, straight

70692 Adjusting knob with cap and nut cap

70021 Cable lug

70031 Rubber foot 25 ∅, 14 high

70045 Rocker switch with lamp, green,

(a1/h1)

70684 Control circuit board RM

(u1)

70590 Socket, 3-pole

(bu1)

70479 Varistor

70694 Insulating sleeve, black

70506 Transformer 5621A

(m1)

70621 Handle with caps

70658 Terminal plug, 2-pole

70698 Terminal plug, 4-pole

polystar® welding tongs 150 - 600 D, 300 - 600 SFZ, 150 + 300 DS

Order number Item

60100 Cheese-head screw M 2.5 x 6 DIN 84 (for terminal plug)

60117 Oval head screw M 3 x 8 DIN 7985 (for carrier/collar)

60161 Oval head screw M 3 x 6 DIN 7985 (for tension spring)

70023 Pressure contact DK 40/41 A complete

70591 Connector, 3-pole

(bu2)

70025 Cable, black, 2 x 1

70026 LED, green, HP 5082/4850

70028 Insulating paper disk

70122 Resistor 750 Ohm, 1/3 w

70535 Clip for green LED

120

GE

- Translation of the original instruction manual -

Page 12 of 15

Order number Item

H33192 Strip-heater carrier 150 D + DS

H33192A Strip-heater carrier 200 D

H33192B Strip-heater carrier 250 DS

H33192C Strip-heater carrier 300 D

H33192D Strip-heater carrier 400 D

H33192G Strip-heater carrier 600 D

H33193 Strip-heater carrier screen 150 D + DS

H33193A Strip-heater carrier screen 200 D

H33193B Strip-heater carrier screen 250 DS

H33193C Strip-heater carrier screen 300 D

H33193D Strip-heater carrier screen 400 D

H33193G Strip-heater carrier screen 600 D

H33294A Strip-heater carrier complete, 150 D + 150 DS

H33294B

Strip-heater carrier complete, 200 D

H33294C

Strip-heater carrier complete, 250 DS

H33294D

Strip-heater carrier complete, 300 D + 300 SFZ

H33294E

Strip-heater carrier complete, 400 D + 400 SFZ

H33294F

Strip-heater carrier complete, 600 D + 600 SFZ

H41043A Tube handle top

H41044 Tube handle bottom

H46881 Insulating bush 4-6881

H46882 Terminal plug, brass, 4-6882

H46883 Insulating plate to drawing, 4-6883

H46884 Strip-heater tension spring 4-6884

H47049-15 Heater element 150 D + DS

H47049-20 Heater element 200 D

H47049-25 Heater element 250 DS

H47049-30 Heater element 300 D + SFZ

H47049-40 Heater element 400 D + SFZ

40097-60 Heater element 600 D + SFZ

H51117A Drive screw, to drawing, 5-1117A

H51118 Arbor, to drawing, 5-1118

H51132 Green deco knob, for push-button switch

H51119B Bearing washer, to drawing, 5-1119B

41149 Tension spring, to drawing , R 4-1149

41150 Clamp bolt, to drawing, R 4-1150

41151 Spring washer, to drawing, R 4-1151

120

GE

- Translation of the original instruction manual -

Page 13 of 15

11. Key

120

GE

- Translation of the original instruction manual -

Page 14 of 15

12. Circuit diagram

120

GE

- Translation of the original instruction manual -

Page 15 of 15

13. EC Declaration of Conformity

The manufacturer RISCHE + HERFURTH GMBH

Kedenburgstraße 53 - 59

22041 Hamburg

herewith certifies that the following product

polystar® film sealer model:

polystar® impulse generator 120 GE

complies with all pertinent provisions of the directive on machinery (2006/42/EC) and the

directive relating to electrical equipment designed for use within certain voltage limits

(2006/95/EC) as well as relevant amending directives (CE labeling).

The product was also subjected to an occupational safety test (GS test) by the following testing

authority:

Test certificate no. NV 13057

Deutsche Gesetzliche Unfallversicherung e.V.

Prüf- und Zertifizierungsstelle

Nahrungsmittel und Verpackung

Fachbereich Nahrungsmittel

Dynamostraße 7 - 11

68165 Mannheim

Person responsible for the documentation: Adalbert Grablowski, tel.: 040-65 69 03-83

Hamburg, 24 April 2013

ppa. Jürgen Symanzik ppa. Gaby Aldag

Table of contents