Rittal SK 3216.480 User manual

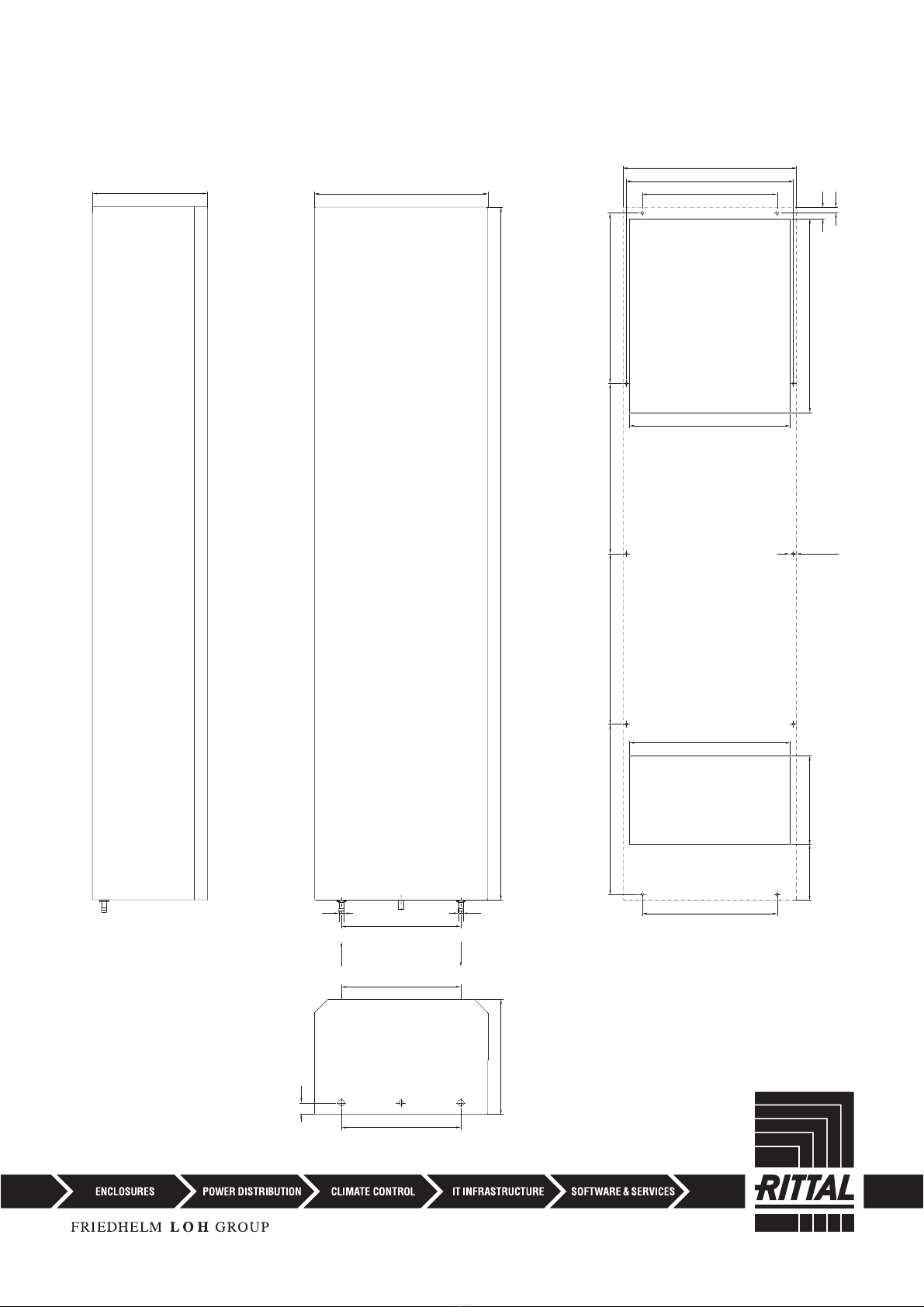

80

500

200

1

/2w

18

75

100

➁

➀

420

200

500

150

Ø 7

420

500

170 50

30

133

150

150

160

200

130

145

160

34

4 x

80

200

950

100

20

77

➁➀

200

(4 x)

140

11

920

175

170 15

475

315 22

126

98

19 920

950

164

140

Ø 7 (6 x)

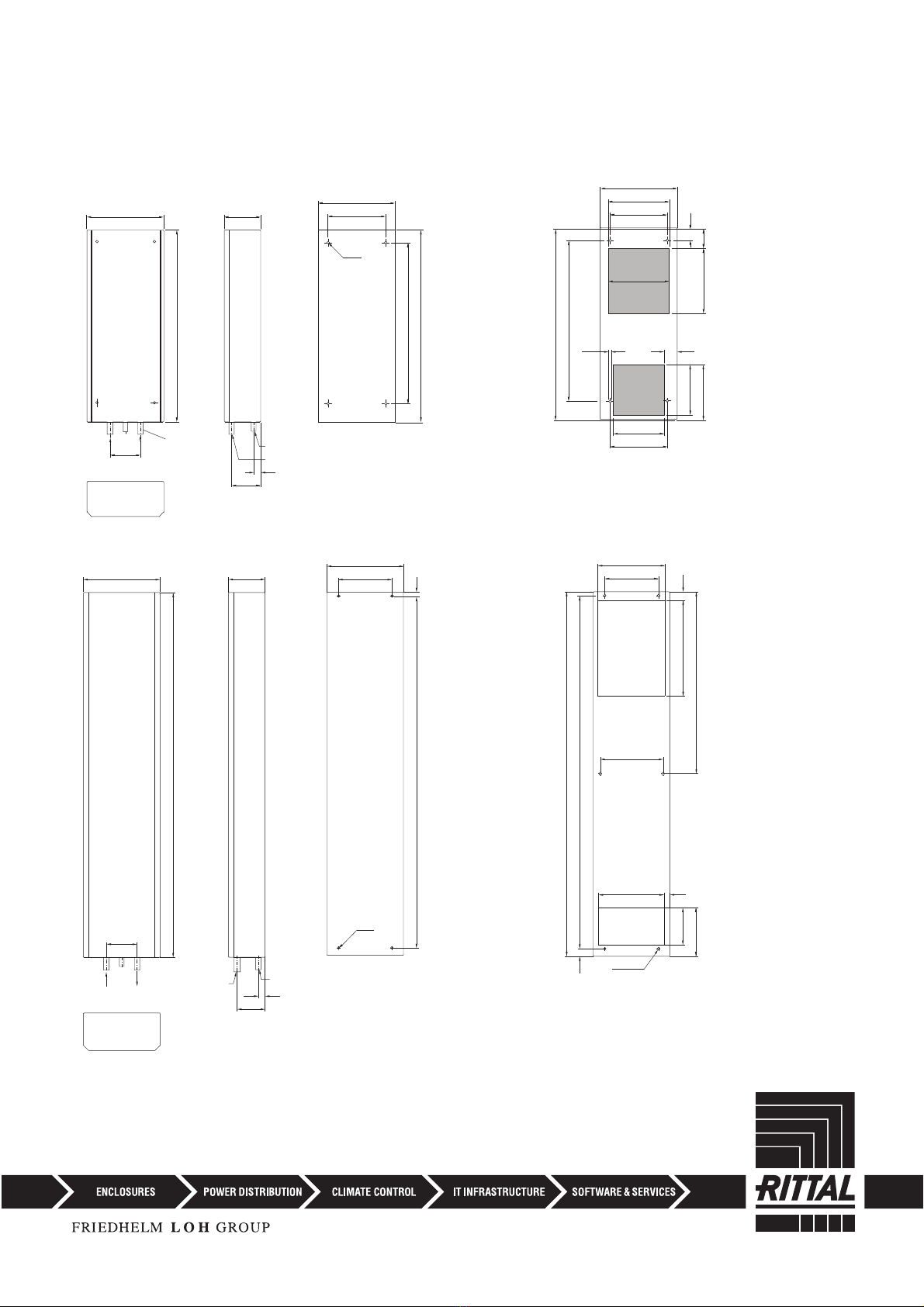

Befestigungsbohrungen Einbau

Fastening holes for internal mounting

Perçages pour montage encastré

Bevestigingsgaten voor inbouw

Montagehålbild, inbyggnad

Fori di fissaggio per installazione incassata

Taladros de fijación para montaje interior

取付穴 全埋め込み取付け

Montageausbruch Anbau

Mounting cut-out for external mounting

Découpe pour montage en saillie

Montage-uitsparingen, aanbouw

Montagehålbild, påbyggnad

Feritoia per installazione sporgente

Escotadura de montaje para montaje exterior

取付用カットアウト 表面取付け

SK 3214.100

SK 3215.100

➀Kondensatablauf

➀Condensate discharge

➀Ecoulement d’eau de condensation

➀Condensafvoer

➀Kondensavlopp

➀Dispositivo di scarico condensa

➀Salida del agua de codensación

➀凝縮水排出器

➁Kühlwasser-Anschluß 1/2˝

➁Cooling water connection 1/2˝

➁ Branchement eau de refroidissement 1/2˝

➁ Aansluiten koelwater 1/2˝

➁ Kylvattenanslutning 1/2˝

➁ Allacciamento liquido frigorigeno 1/2˝

➁ Acometida de 1/2˝ del agua de refrigeración

➁給水部 1/2 インチ

Ø 7

Ø 7

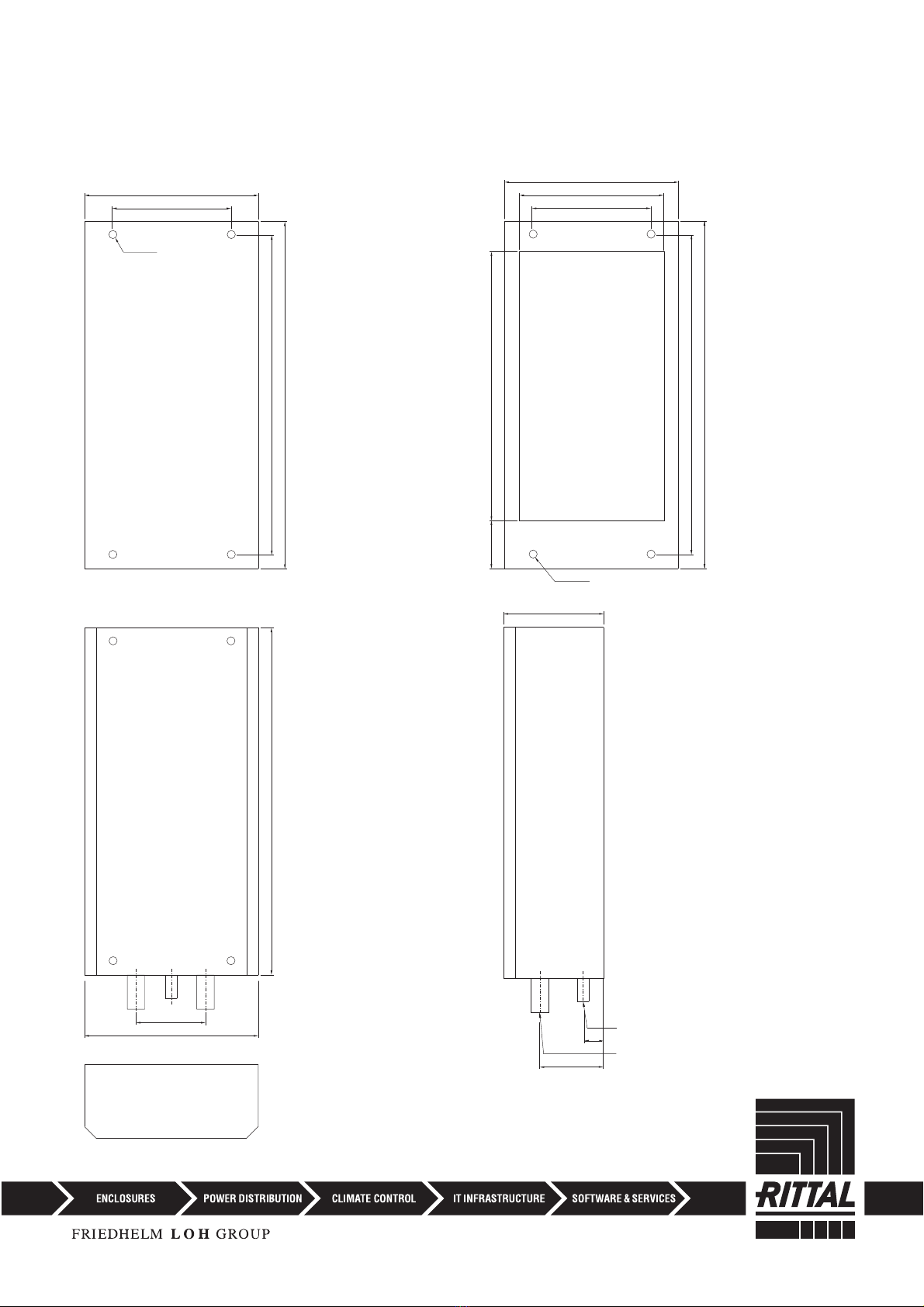

2

air/water heat exchanger

300 451

310

310

310

30

1800

300

11

SK 3216.480 451

Ø 8 (10 x)

433.5

350

417

442.5

230

145

442.5 442.5 442.5

530

30

15

417

350

Montageausbruch Anbau

Mounting cut-out for external mounting

Découpe pour montage en saillie

Montage-uitsparingen, aanbouw

Montagehålbild, påbyggnad

Feritoia per installazione sporgente

Escotadura de montaje para montaje exterior

取付用カットアウト 表面取付け

/2w

/2w

3

air/water heat exchanger

300

150

60

➁

➀

85

18

55

300

276

102

150

Ø 7 (4 x)

300

276

232

41

150

125

102

Ø 7 (4 x)

Befestigungsbohrungen Einbau

Fastening holes for internal mounting

Perçages pour montage encastré

Bevestigingsgaten voor inbouw

Montagehålbild, inbyggnad

Fori di fissaggio per installazione incassata

Taladros de fijación para montaje interior

取付穴 全埋め込み取付け

Montageausbruch Anbau

Mounting cut-out for external mounting

Découpe pour montage en saillie

Montage-uitsparingen, aanbouw

Montagehålbild, påbyggnad

Feritoia per installazione sporgente

Escotadura de montaje para montaje exterior

取付用カットアウト 表面取付け

SK 3212.xxx

➀Kondensatablauf

➀Condensate discharge

➀Ecoulement d’eau de condensation

➀Condensafvoer

➀Kondensavlopp

➀Dispositivo di scarico condensa

➀Salida del agua de codensación

➀凝縮水排出器

➁Kühlwasser-Anschluß 3/8˝

➁Cooling water connection 3/8˝

➁ Branchement eau de refroidissement 3/8˝

➁ Aansluiten koelwater 3/8˝

➁ Kylvattenanslutning 3/8˝

➁ Allacciamento liquido frigorigeno 3/8˝

➁ Acometida de 3/8˝ del agua de refrigeración

➁給水部 3/8 インチ

4

air/water heat exchanger

Tab. 2.1 Technische Daten

Tab. 2.1 Technical data

Tab. 2.1 Données techniques

Tab. 2.1 Technische gegevens

Tab. 2.1 Tekniska data

Tab. 2.1 Caratteristiche tecniche

Tab. 2.1 Datos técnicos

図2.1 仕様

Bemessungsbetriebs-

spannung

Bemessungs-

strom

Vor-

sicherung

T

Einschalt-

dauer

Nutzkühlleistung Kühlmedium:

Wasser

(s. Spezifikation)

Wasservorlauf-

temperatur

Umgebungs-

temperatur-

bereich

Betriebs-

druck

Geräusch-

pegel

Schutzart

Innenkreislauf

Außenkreislauf

Abmessungen

(B x H x T)

mm

Gewicht Farbton

Operating

voltage

Rated

current

Pre-fuse

T

Duty cycle Useful cooling

output

Refrigerant:

Water

(see specification)

Water inlet

temperature

Ambient

temperature

Operating

pressure

Noise

level

Protection categ.

Internal circuit

External circuit

Dimensions

(W x H x D)

mm

Weight Colour

Tension

nominale

Courant

nominal

Dispositif

de sécurité

T

Durée de

mise en

circuit

Puissance

frigorifique en

régime permanent

Fluide frigorigène:

de l’eau (voir les

spécifications)

Température de

l’eau à l’entrée

Température

ambiante

Pression

de régime

Niveau

sonore

Ind. de protect.

Circuit intérieur

Circuit extérieur

Dimensions

(L x H x P)

mm

Poids Teinte

Bedrijfs-

spanning

Nominale

stroom

Voor-

zekering,

traag T

Inschakel-

duur

Nuttig

koelvermogen

Koelmedium:

Water

(zie specificatie)

Waterinlaat-

temperatuur

Omgevings-

temperatuur-

bereik

Bedrijfs-

druk

Geluidsnivo Beschermklasse

Inwendig circuit

Uitwend. circuit

Afmetingen

(B x H x D)

mm

Gewicht Kleur

Märkspänning Märkström Försäkring

T

Inkopp-

lingstid

Effektiv

kyleffekt

Kylmedel:

Vatten

(se specifikation)

Tillvatten-

temperatur

Omgivnings-

temperatur

Vattentryck Ljudnivå Kapslingsklass

Inre kretslopp

Yttre kretslopp

Mått

(B x H x D)

mm

Vikt Färgton

Tensione

nominale

Corrente

nominale

Fusibile

ritardato T

Intermit-

tenza

Potenza

frigorifera utile

Mezzo frigorifero:

Acqua

(vedi specifica)

Temperatura

di ingresso

dell’acqua

Campo di

temperatura

d’impiego

Pressione

di

esercizio

Livello di

rumorosità

Grado di protez.

Circuito interno

Circuito esterno

Dimensioni

(L x A x P)

mm

Peso Colore

Tensión

de servicio

Intensidad

nominal

Fusible T Duración

de

conexión

Potencia

frigorífica útil

Agente refrigerante:

Agua

(ver especificación)

Temperatura

del agua de

entrada

Campo de

temperatura

ambiente

Presión

máxima

admisible

Nivel

de ruido

Protección

Circuito interior

Circuito exterior

Dimensiones

(anch. x alt.

x prof.) mm

Peso Color

定格電圧 定格電流 バック

アップ

ヒューズ

デュー

ティサイ

クル

有効冷却能力 冷却材:水

( 冷却材仕様

参照)

注入時水温 外部温度

範囲

動作圧 騒音

レベル

保護等級

内部回路

外部回路

外形寸法

(幅 x 高さ x 奥

行)mm

質量

カラー

L35 W10, 200 l/h

L35 W10, 400 l/h EN 60 529

SK 3212.024

24 V DC, 1,20 A 2,0 A

100% 300 W (200 l/h) > +1°C –

+30°C

+1°C –

+70°C 1 – 10 bar 42 dB (A) IP 55 150 x 300 x 80 3 kg RAL

7035

SK 3214.100

230 V,

50/60 Hz

0,17 A/

0,18 A

2,0 A/

2,0 A 100 % 600 W (200 l/h)

650 W (400 l/h)

> +1°C –

+30°C

+1°C –

+70°C 1 – 10 bar 42 dB (A) IP 55 200 x 500 x 100 7 kg RAL

7035

SK 3217.100

230 V,

50/60 Hz

0,60 A/

0,55 A

4,0 A/

4,0 A 100 % 1000 W (200 l/h)

1100 W (400 l/h)

> +1°C –

+30°C

+1°C –

+70°C 1 – 10 bar 44 dB (A) IP 55 298 x 520 x 135 9,5 kg RAL

7035

SK 3215.100

230 V,

50/60 Hz

0,38 A/

4,0 A

4,0 A/

4,0 A 100 % 1250 W (200 l/h)

1300 W (400 l/h)

> +1°C –

+30°C

+1°C –

+70°C 1 – 10 bar 53 dB (A) IP 55 200 x 950 x 100 13 kg RAL

7035

SK 3216.480

400 V, 3~, 50/60 Hz

480 V, 3~, 60 Hz

1,4 A/1,6 A

1,2 A

4,0 A/

4,0 A 100% 7000 W (500 l/h) > +1°C –

+30°C

+1°C –

+70°C 1 – 10 bar 70 dB (A) IP 55 450 x 1800 x 300 79 kg RAL

7035

D

GB

F

NL

S

I

E

J

5

air/water heat exchanger

English

4. Electrical connection

The connection voltage and frequency must cor-

respond to the rated values quoted on the data

plate. The unit must be connected to the mains

via a disconnection device which ensures at least

3 mm contact opening in the deactivated state.

No additional temperature control must be con-

nected to the supply side of the unit. Line protec-

tion should be provided by means of the pre-fuse

specified on the name plate. Please observe the

relevant regulations when installing!

The mains connection is made at the connec-

tion terminal

5. Cooling water

connection

The cooling water connection must be made with

pressure resistant flexible hoses which should be

secured with clips.

(Note the direction of flow and check for

absence of leaks!)

The units have no separate air-bleed. With

pressure-sealed systems, corresponding air-

bleed facilities are to be installed on the water

side.

Protect the water circuit from contamination and

excess pressure (10 bar max.).

Please observe the relevant regulations when

installing!

6. Refrigeration and

control behaviour

The fan of the air circuit operates continuously,

thus ensuring an even temperature distribution

within the enclosure. A solenoid valve controls the

cooling water flow in accordance with the preset

temperature. Setting range +20°C to +60°C.

Presetting of the enclosure temperature is made,

6.1 for SK 3214.100 / SK 3215.100 /

SK 3216.480

via the thermostat on the rear of the unit.

6.2 SK 3212.xxx has no control unit.

7. Leaks and temperature

monitoring

7.1 Temperature monitoring

Should the temperature inside the enclosure rise

by more than

10 K in the models SK 3214.100 / SK 3215.100

SK 3216.480

For SK 3214.100 / SK 3215.100 / SK 3216.480

the connection of the potential-free contact is

made via the plug-in terminal strip on the rear of

the unit.

7.2 Leak monitoring

In the event of a leakage developing

a pipe fracture occurring in the water circuit

a) the cooling water supply will be cut

off immediately,

b) the potential-free changeover contact will

be switched, and

c) the fan will be switched off.

8. Maintenance

The air/water heat exchangers require no main-

tenance (see point 12.).

Check the function of the condensate draining

facility regularly.

9. Scope of supply

and warranty

3212.xxx / SK 3214.100 / SK 3215.100 /

SK3216.480

1 air/water heat exchanger, ready for connection

1 sealing tape

4 fastening bolts

(internal installation of unit 3247.000)

4 threaded pins M6 x 30

(internal installation of unit)

4 flat-headed screws M6*

4 fixing rings*

4 nuts M6

4 washers A 6.4

4 protective caps

1 set of assembly and operating instructions

1 drilling template

* Only for SK 3214.100 / SK 3215.100 /

SK 3216.480

instead of the threaded pins.

Guarantee:

This unit is covered by a 1-year guarantee from

the date of supply, subject to correct usage.

Within this period, the returned unit will be

repaired in the factory or replaced free of charge.

The unit is to be used for the cooling of enclosures

only. If it is connected or handled improperly the

manufacturer’s guarantee does not apply and in

this case we are not liable for any damage

caused.

Contents

1. Application

2. Technical data

3. Assembly

4. Electrical connection

5. Cooling water connection

6. Refrigeration and control behaviour

7. Leaks and temperature monitoring

8. Maintenance

9. Scope of supply and warranty

10. Safety instructions

11. Notes on water quality

12. Spares lis

1. Application

Air/water heat exchangers are designed and

built to dissipate heat from enclosures, by cool-

ing the air inside the enclosure and protecting

temperature sensitive components. Air/water

heat exchangers are particularly suitable for the

temperature range of +40°C to +70°C, where for

system related reasons, comparable units such

as air/air heat exchangers, enclosure cooling

units or fan units with filters cannot be used to

dissipate heat effectively and economically.

2. Technical data

(see table 2.1).

3. Assembly

Please use the enclosed drilling template to cut

out the component apertures.

SK 3212.230 / SK 3214.100 / SK 3215.100 / SK

3216.480

External installation of the unit

Screw the four fastening bolts ➀, together with

the washer ➁and nut ➂, to the mounting level

➃ of the enclosure. Push the heat exchanger ➄

into position and secure with four screws ➅.

Internal installation of the unit (Fig. page 30):

Insert four fastening bolts ➀into the appliance

from behind. Slide the fixing ring ➆onto the

fastening bolts as a mounting aid. Screw the

appliance, together with the washer ➁and nut

➂, to the mounting level of the enclosure from

the outside. Push the protective cap ➇onto the

nut.

10. Safety instructions

● When installing the device, the condensate

discharge must be routed out of the enclosure!

● In order to avoid frost damage, the minimum

permissible water temperature of +1°C must

not be undercut at any point in the water cycle!

● It is essential to obtain the manufacturer’s

permission before adding anti-freeze!

● During storage and transportation below

freezing point, the water cycle should be

drained completely using compressed air!

● Only set the thermostat as low as is strictly

necessary, because of undercutting the dew

point with a falling water inlet temperature

(condensation)!

● It is very important that the enclosure is sealed

on all sides (IP 54), particularly the cable entry

(condensation)!

6

air/water heat exchanger

11. Notes on water quality For safe operation of the

equipment, it is essential to observe the VBG guidelines on cooling water (VGB

R 455 P).

Cooling water must not contain any limescale deposits or loose debris; in other

words, it should have a low level of hardness, particularly a low level of carbon

hardness. For recooling within the plant, the carbon hardness should not be too

high. On the other hand, however, the water should not be so soft that it attacks

the operating materials. When recooling the cooling water, the salt content

should not be allowed to increase excessively due to the evaporation of large

quantities of water, since electrical conductivity increases as the concentration

of dissolved sub-stances rises, and the water thereby becomes more corrosive.

For this reason, not only is it always necessary to add a corresponding quan-tity

of fresh water, but also to remove part of the enriched water.

Gypsiferous water is unsuitable for cooling purposes because it has a

tendency to form boiler scale, which is particularly difficult to remove.

Furthermore, cooling water should be free from iron and manganese,

because otherwise deposits may occur which settle in the pipes and

block them. At best, organic substances should only be present in

small quantities, because otherwise sludge deposits and

microbiological contamination may occur.

12.1 Preparation and maintenance

of the water in recooling systems

Depending on the type of installation to be cooled, certain

requirements are placed on the cooling water with respect to purity.

According to the level of contamination and the size and design of the

recooling systems, a suitable process is used to prepare and/or

maintain the water. The most common types of contamination and most

frequently used techniques to elimin-ate them in industrial cooling are:

Contamination of the water Procedure

Mechanical contamination

Filtering of water via

– Mesh filter

– Gravel filter

– Cartridge filter

– Precoated filter

Excessive hardness Water softening via ion exchange

Moderate content of mechanical contaminants

and hardeners Addition of stabilisers and/or dispersing

agents to the water

Moderate content of chemical contaminants Addition of passifiers and/or inhibitors

to the water

Biological contaminants, slime bacteria and algae Addition of biocides to the water

In order to ensure correct operation of a recooling system which is operated with water on at least one side, the properties of the

added or system

SK 3212.xxx / SK 3214.100 /

SK 3215.100 / SK 3216.480

Hydrological data

pH value 7 – 8.5

Carbonate hardness > 3 < 8 °dH

Free carbon dioxide 8 – 15 mg/dm3

Accompanying carbonic acid 8 – 15 mg/dm3

Aggressive carbonic acid 0 mg/dm3

Sulphides free

Oxygen < 10 mg/dm3

Chloride ions < 50 mg/dm3

Sulphate ions < 250 mg/dm3

Nitrates and nitrites < 10 mg/dm3

COD < 7 mg/dm3

Ammonia < 5 mg/dm3

Iron < 0.2 mg/dm3

Manganese < 0.2 mg/dm3

Residue on evaporation < 500 mg/dm3

Potassium permanganate consumption < 25 mg/dm3

Suspended matter

< 3 mg/dm3

> 3 < 15 mg/dm3part current purification recommended

> 15 mg/dm3continuous purification recommended

water used should not deviate substantially from the following list of hydrological data:

1) The complete absence of corrosion under experimental conditions suggests that solutions with a

significantly higher salt content and greater corrosion potential (such as seawater) may still be

tolerated.

7

air/water heat exchanger

Ersatzteil-

liste Spares

list

Liste de

pièces

détachées

Lijst

reserve-

delen

Reserv-

delslista

Lista dei

pezzi di

ricambio

Lista de

piezas de

repuesto

スペア

パーツ

Bezeichnung Description Signification Benaming Beteckning Descrizione Descripción 製品名

10 Ventilator,

komplett Fan,

complete Ventilateur,

complète Ventilator,

kompleet Fläkt,

komplett Ventilatore,

completa Ventilador,

completo ファン、

一式

15 Zubehörbeutel Dispatch bag Pochette

d’accessoires Zakje toebehoren Tillbehörspåse Sacchetto

accessori Bolsa de

accesorios アクセサリー

バッグ

16 Abdichtplatte Sealing plate Plaque

d’étanchéité Afdichtplaat Tätningsplatta Piastra di tenuta Placa de

estanqueidad 密閉用プレート

32 Magnetventil,

komplett Solenoid valve,

complete Vanne électroma-

gnétique, complète Magneetventiel,

kompleet Magnetventil,

komplett Valvola elettromag-

netica, completa Electroválvula,

completa マグネットバルブ、

一式

33 Rückschlagventil Flap valve Clapet antiretour Terügstroomventiel Backventil Valvola di

non ritorno Válvula de

retención フラップバルブ

35 Zwei-Stufen-

Thermostat Two-stage

thermostat Thermostat

à deux paliers Tweestanden-

thermostaat Tvåstegs-

termostat Termostato

a due stadi Termostato

de dos estados 二段階式

サーモスタット

40 Steuerplatine

komplett Control PCB

complete Platine de com-

mande, complète Stuurstroomprint,

kompleet Styrkort,

komplett Piastra circuito

stampate, completa Pletina de mando

completa コントロールPCB、

一式

48 Lufteintrittsgitter Air inlet grille Grille d’entrée d’air Luchtinlaatrooster Luftingångsgaller Griglia d’entrata

dell’aria Rejilla de entrada

de aire 吸気グリッド

71 Temperaturfühler Temperature

sensor Sonde de

température Temperatuursensor Temperaturgivare Sonda di

temperatura Sonda térmica 温度センサー

73 Leckagesensor Leakage sensor Palpeur de fuite Lekkagesensor Läckagesensor Rivelatore

di perdite Sensor de fugas

de agua 漏水モニター

75 Haube,

komplett Cover,

complete Couvercle,

complète Afdekkap,

kompleet Huv,

komplett Calotta,

completa Cubierta

completa カバー、

一式

91 Wärmetauscher Heat exchanger Echangeur

thermique Warmtewisselaar Värmeväxlare Scambiatore

di calore Intercambiador

de calor ヒートエクスチェン

ジャー

95 Bodenwanne,

komplett Base tray,

complete Bac de rétention,

complète Bodemplaat,

kompleet Bottentråg,

komplett Vaschetta di racc.

cond., completa Bandeja de base

completa ベーストレイ、

一式

DEJ

GB NL I

FS

Position

Item

Pos.

Pos.

Pos.

Pos.

Posición

項目

Bei Bestellung unbedingt angeben

Typ:

Fabrikations-Nr.:

Herstelldatum:

Ersatzteil-Nr.:

Absolutely necessary in case of order

Type:

Fabrication no.:

Manufacturing date:

Spare part no.:

スペアパーツご発注時に必ずご記入下さい。

クーラー型式:

製造番号:

製造日時:

スペアパーツ番号:

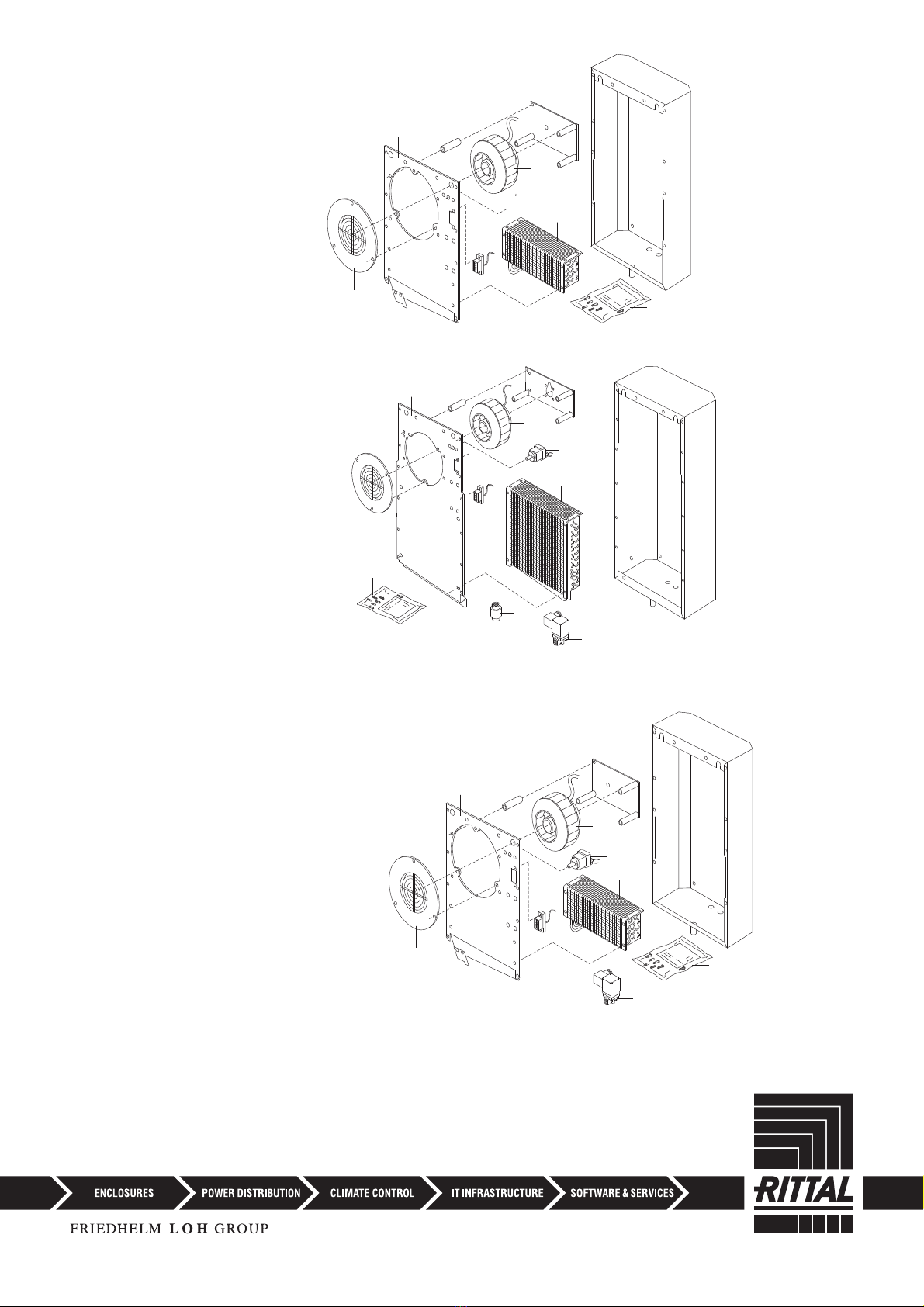

12. Spares list

8

air/water heat exchanger

32

33

35

91

48

15

10

75

SK 3216.480

75

10

91

48

15

SK 3212.xxx

SK 3212.230 / SK 3214.100 /

SK 3215.100

32

75

10

35

91

48

15

*

*

9

air/water heat exchanger

6514283271

5

4

Geräteanbau

External mounting

Montage en saillie

Apparaatopbouw

Påbyggnad

Montaggio sporgente

Montaje exterior del aparato

表面取付け

Geräteeinbau

Internal mounting

Montage encastré

Apparaatinbouw

Inbyggnad

Montaggio incassato

Montaje interior del aparato

全埋め込み取付け

3

Geräteanbau

External mounting

Montage en saillie

Apparaatopbouw

Påbyggnad

Montaggio sporgente

Montaje exterior del aparato

表面取付け

Geräteeinbau

Internal mounting

Montage encastré

Apparaatinbouw

Inbyggnad

Montaggio incassato

Montaje interior del aparato

全埋め込み取付け

Abb. 3.2 Anbringung der Dichtung

Fig. 3.2 Attaching the seal

Fig. 3.2 Mise en place du joint

Afb. 3.2 Aanbrengen van de afdichting

Bild 3.2 Montage av tätning

Fig. 3.2 Applicazione della guarnizione

Fig. 3.2 Colocación de la junta

図3.2 パッキンの取付

SK 3212.xxx / SK 3214.100 /

SK 3215.100 / SK 3216.480

SK 3212.xxx / SK 3214.100 /

SK 3215.100 / SK 3216.480

SK 3212.xxx / SK 3214.100 /

SK 3215.100 / SK 3216.480

SK 3212.xxx / SK 3214.100 /

SK 3215.100 / SK 3216.480

10

air/water heat exchanger

SK 3212.230

Anschlußplan

Wiring diagram

Schéma des connexions

Aansluitschema

Anslutningsdiagram

Schema di allacciamento

Esquema de conexiones

配線図

024

M

1~

C1

M1

X10

L1 N

X11

X20

SK 3212.230

Anschlußplan

Wiring diagram

Schéma des connexions

Aansluitschema

Anslutningsdiagram

Schema di allacciamento

Esquema de conexiones

配線図

230

11

air/water heat exchanger

1~

32

X10 3

C1

F1.2

Y1

14

31

T

34

M1

45

X20

X10

L1 N

T

11

F1.1

SK 3214.100 / SK 3215.100

Wiring diagram

Schéma des connexions

Aansluitschema

Anslutningsdiagram

Schema di allacciamento

Esquema de conexiones

配線図

Technische Daten siehe Typenschild

Technical data see name plate

Données techniques voir plaque signalétique

Technische gegevens zie typeplaatje

Tekniska data se typskylten

Caratteristiche tecniche vedi dati di targa

Datos técnicos ver placa de características

仕様については銘板参照

M

SK 3216.480

Anschlußplan

Wiring diagram

Schéma des connexions

Aansluitschema

Anslutningsdiagram

Schema di allacciamento

Esquema de conexiones

配線図

12

air/water heat exchanger

Anschlußschema

A1 = Steuerplatine

B1 = Temperaturfühler

B2 = Leckagefühler

C1 = Betriebskondensator

F1 = Thermostat

F1.1 = Schaltkontakt

F1.2 = Störmeldekontakt

M1 = Ventilator

Y1 = Magnetventil

X1 = Klemmleiste

X10 = Stecker Netzanschluß (schwarz)

X11 = Stecker Sammelstörmeldung (braun)

X12 = Gerätesteckanschluß TW

X20 = Steckverbindung Ventilator

P1 = Sollwert-Potentiometer

Schrankinnentemperatur

ABC = Umschaltung der Betriebsart

Aansluitschema

A1 = Stuurstroomprint

B1 = Temperatuursensor

B2 = Lekkagesensor

C1 = Bedrijfskondensator

F1 = Thermostaat

F1.1 = Schakelaar

F1.2 = Storingsmelderkontakt

M1 = Ventilator

Y1 = Magneetventiel

X1 = Klemmenstrook

X10 = Stekker netaansluiting (zwart)

X11 = Stekker verzamelsfoormelding

(bruin)

X12 = Connectoraansluiting TW

X20 = Connector voor ventilator

P1 = Temperatuur in kast

ABC = Omschakeling van bedrijfsstand

Esquema

de conexiones

A1 =

Pletina de mando

B1 =

Sensor de temperatura

B2 =

Sensor de fugas

C1 =

Condensador de servicio

F1 = Termostato

F1.1 = Contacto de conexión

F1.2 = Contacto de aviso de averia

M1 =

Ventilador

Y1 = Válvula electromagnética

X1 = Regleta de bornes

X10 = Enchufe alimentación de red (negro)

X11 = Enchufe aviso de avería colectiva

(marrón)

X12 = Conexión de enchufe del aparato TW

X20 = Conexión ventilador

P1 = Valor teórico potenciómetro

temperatura interior armario

ABC =

Conmutación de la clase de servicio

D

NL

E

Wiring diagram

A1 = Control PCB

B1 = Temperature sensor

B2 = Leak sensor

C1 = Operating capacitor

F1 = Thermostat

F1.1 = Switch contact

F1.2 = Fault signal contact

M1 = Fan

Y1 = Solenoid valve

X1 = Terminal strip

X10 = Mains plug connector (black)

X11 = Collective fault signal plug (brown)

X12 = Unit plug connector TW

X20 = Plug connection fan

P1 = Set-point setter,

enclosure internal temperature

ABC = Changeover of operating mode

Anslutningsschema

A1 = Styrkort

B1 = Temperaturavkännare

B2 = Läckageavkännare

C1 = Driftkondensator

F1 = Termostat

F1.1 = Omkopplare

F1.2 = Felmeddelande

M1 = Fläkt

Y1 = Magnetventil

X1 = Klämlist

X10 = Kontakt nätanslutning (svart)

X11 = Kontakt störsignaler (brun)

X12 = Aggregatuttag TW

X20 = Anslutning fläkt

P1 = Apparatskåpets innertemperatur

ABC = Växling av funktion

配線図

A1 = 制御PCB

B1 = 温度センサー

B2 = 漏水センサー

C1 = 操作用コンデンサー

F1 = サーモスタット

F1.1 = スイッチ接点

F1.2 = エラー信号接点

M1 = ファン

Y1 = マグネットバルブ

X1 = ターミナルストリップ

X10 = 電源プラグ(黒)

X11 = 集合故障信号プラグ(茶)

X12 = ユニットプラグコネクタ TW

X20 = プラグ接続式ファン

P1 = 設定値ポテンシャルメータ

エンクロージャー内部温度用

ABC = 運転モード切替

GB

S

J

Schéma électrique

A1 = Platine de commande

B1 = Sonde de température

B2 = Sonde de niveau d’eau

C1 = Condensateur de régime

F1 = Thermostat

F1.1 = Contact de commutation

F1.2 = Contact de signalisation de défaút

M1 = Ventilateur

Y1 = Vanne électromagnétique

X1 = Bornier

X10 = Bornes de raccordement secteur (noir)

X11 = Bornes de raccordement des

indications de défaut (brun)

X12 = Connecteur enfichable TW

X20 = Fiche du ventilateur

P1 = Potentiomètre de réglage de la

température intérieure de l’armoire

ABC =

Commutation du mode

de fonctionnement

Schema allacciamenti

A1 = Piastra circuito stampate

B1 = Sonda di temperatura

B2 = Rivelatore (sonda) di predita

C1 = Condensatore d’esercizio

F1 = Termostato

F1.1 = Contatto degli interruttori

di distribuzione

F1.2 = Contatto di segnalazione guasti

M1 = Ventilatore

Y1 = Valvola elettromagnetica

X1 = Morsettiera

X10 =

Spina allacciamento rete (nero)

X11 =

Spina circuito de segnalazione

(marrone)

X12 = Allacciamento apparecchio TW

X20 = Connettore per ventilatore

P1 = Regolazione della temperatura interna

ABC = Commutazione del tipo esercizio

F

I

13

air/water heat exchanger

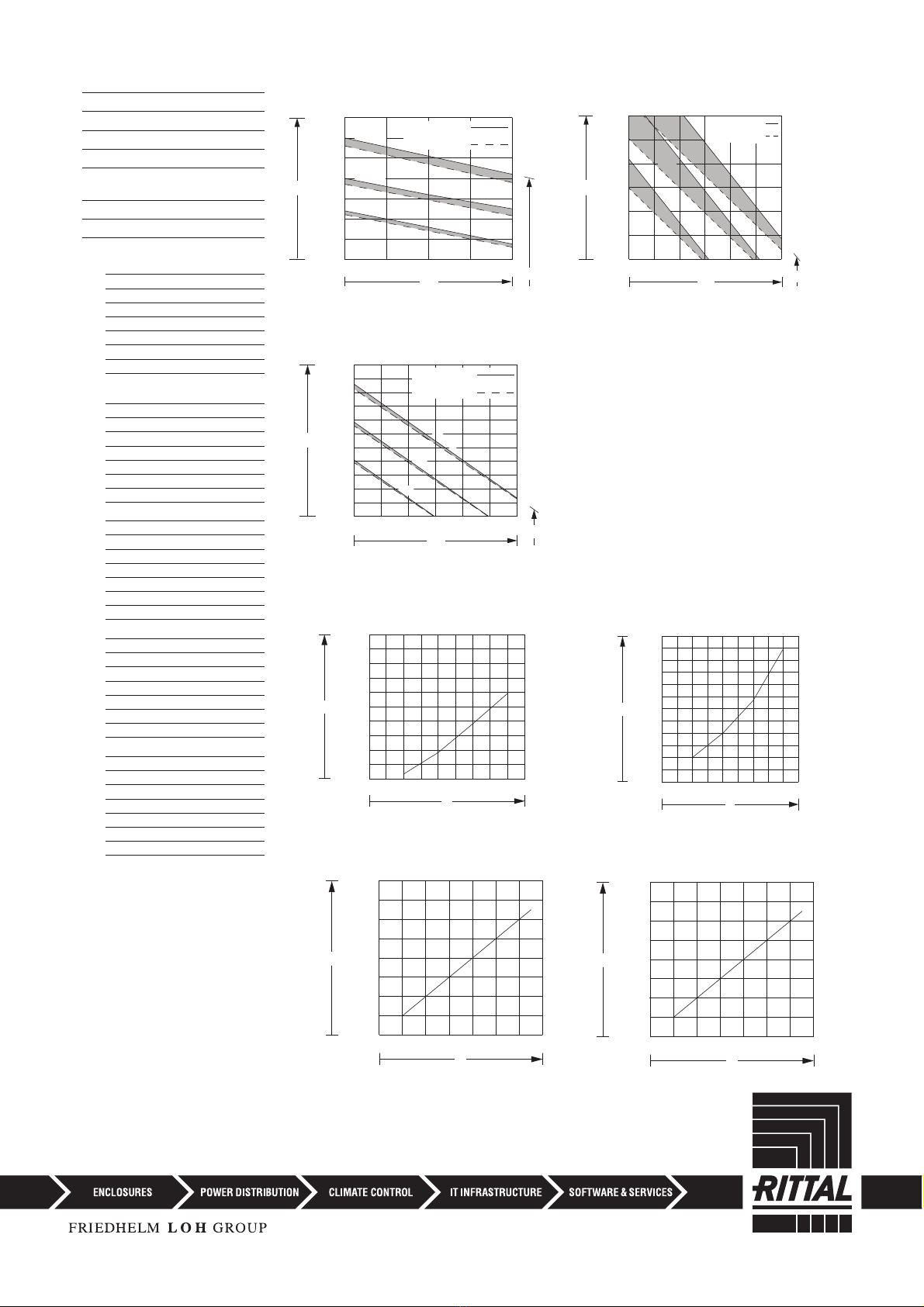

Kennlinienfeld (DIN 3168)

Performance diagram

Diagramme aéraulique

Karakteristiek

Karakteristik kurva

Diagramma delle curve

caratteristiche

Diagrama de potencia

動作性能表

700

600

500

400

300

200

100

10 15 20

QK

.

TW

Ti

VW= 400 l/h

.

VW= 200 l/h

.

45 °C

35 °C

25 °C

5

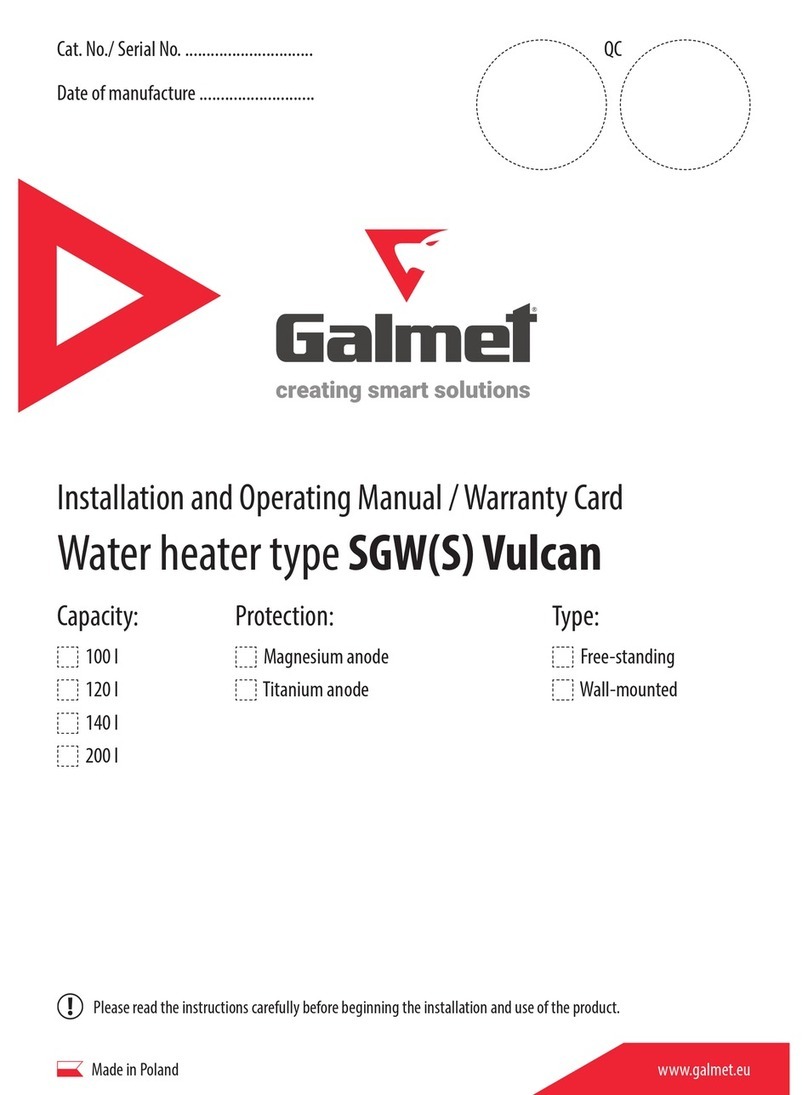

1000

10 15 20 25 3530

2000

3000

4000

5000

6000

7000

45 °C

35 °C

25 °C

QK

.

TWTi

VW

= 500 l/h

VW

= 400 l/h

.

.

ΔP

V

200100 300 400

800

600

400

200

1000

.

ΔP

V

200100 300 400

1000

800

600

200

400

1200

.

Dauer-Nutzkühlleistung [W]

Continuous useful cooling output

Puissance frigo. en régime permanent

Nuttig koelvermogen

Kyleffekt

Potenza frigorifera utile

Potencia útil de refrigeración

冷却能力

Q

·K=

Schaltschrank-

Innentemperatur [°C]

Enclosure internal temperature

Température à l’interieur de l’armoire

Temperatuur in de kast

Temperatur inne i skåpet

Temperatura interna dell’armadio

Temperatura interior armario

エンクロージャー内部温度

Ti=

Wassereintrittstemperatur [°C]

Water inlet temperature

Température de l’eau à l’entrée

Waterinlaattemperatuur

Vattnets ingångstemperatur

Temperatura d’ingresso dell’acqua

Temperatura de entrada del agua

注入時水温

Tw=

Kennlinienfeld SK 3216.480

(DIN 3168) (50/60 Hz)

Volumenstrom [l/h]

Volume flow

Débit d’air

Volumestroom

Volymström

Portata

Caudal volumétrico

水量

V

.=

Wasserwiderstand [m/bar]

Water resistance

Résistance hydraulique

Waterweerstand

Vattenmotstånd

Resistenza dell’acqua

Resistencia del agua

耐水圧

6P=

Kennlinienfeld SK 3212.xxx

(DIN 3168) (50/60 Hz)

Wasserwiderstandskennlinie

SK 3216.480

Wasserwiderstandskennlinie

SK 3212.xxx

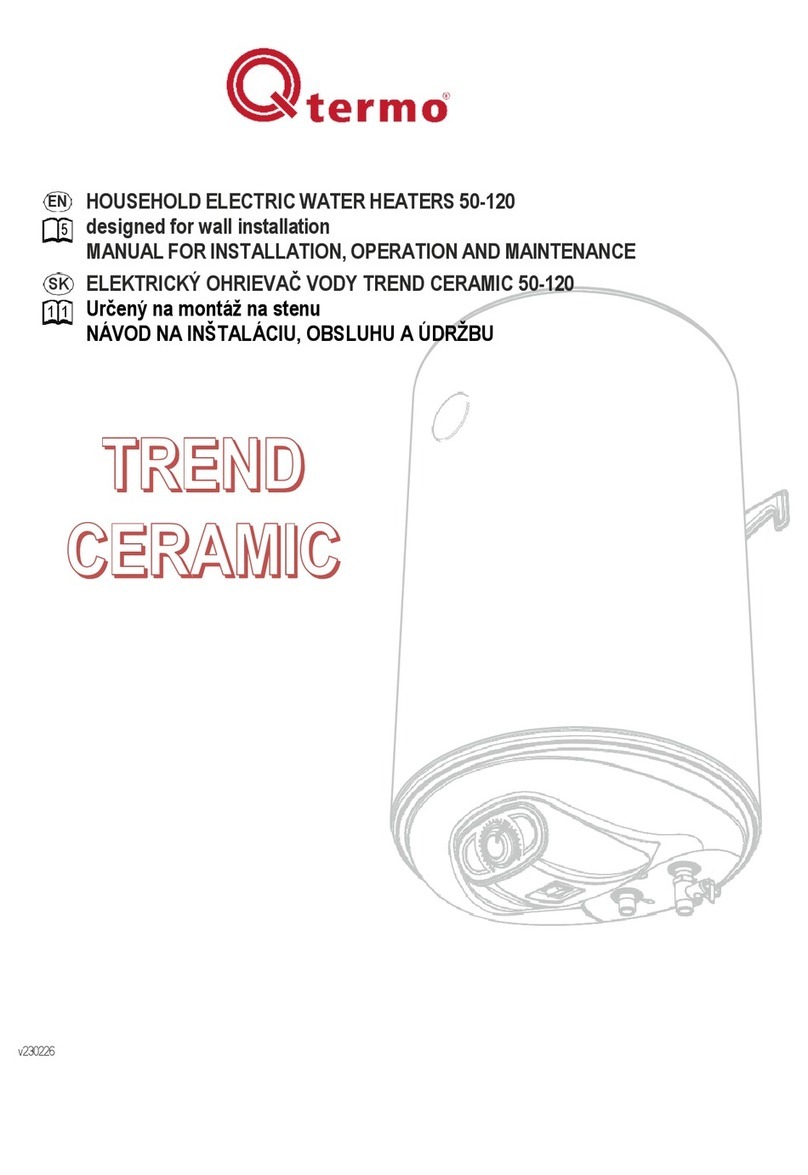

2400

2200

2000

1600

1400

1200

1000

800

600

400

200

510 15 20 25 30 35

45°C

35°C

25°C

VW= 400 l/h

.

VW= 200 l/h

.

QK

.

TW

Ti

Kennlinienfeld SK 3215.100

(DIN 3168) (50/60 Hz)

ΔP

V

.

300 400 500

300

200

100

400

ΔP

V

.

200 300 400

300

200

100

400

Wasserwiderstandskennlinie

SK 3214.100

Wasserwiderstandskennlinie

SK 3215.100

14

air/water heat exchanger

◾Enclosures

◾ Power Distribution

◾ Climate Control

◾ IT Infrastructure

◾ Software & Services

You can find the contact details of all

Rittal companies throughout the world here.

www.rittal.com/contact

RITTAL GmbH & Co. KG

Postfach 1662 · D-35726 Herborn

Phone +49(0)2772 505-0 · Fax +49(0)2772 505-2319

6st edition 07 / 2019 / ID no. 239952

15

air/water heat exchanger

This manual suits for next models

3

Table of contents

Popular Water Heater manuals by other brands

Galmet

Galmet SGW 120 Installation and operating manual / warranty card

AquaStar

AquaStar 80 VP Install and operation instructions

AEG

AEG U5 Operation and installation

Qtermo

Qtermo TREND 50 CERAMIC MANUAL FOR INSTALLATION, OPERATION AND MAINTENANCE

EDN

EDN RADIASOL T150 Technical manual

Bradford White

Bradford White 50T Specification sheet

WarmFlow

WarmFlow Cylinder Passport User instructions

Invest

Invest ISP 2.0 installation manual

Enviroheat

Enviroheat 200EH1-14 Operation and installation manual

Nibe

Nibe VPB 500 User's and installer's manual

Rheem

Rheem Gas Domestic Indoor Water Heater Installation and owner's guide

Noritz

Noritz GQ-C2857WS-FF US installation manual