3

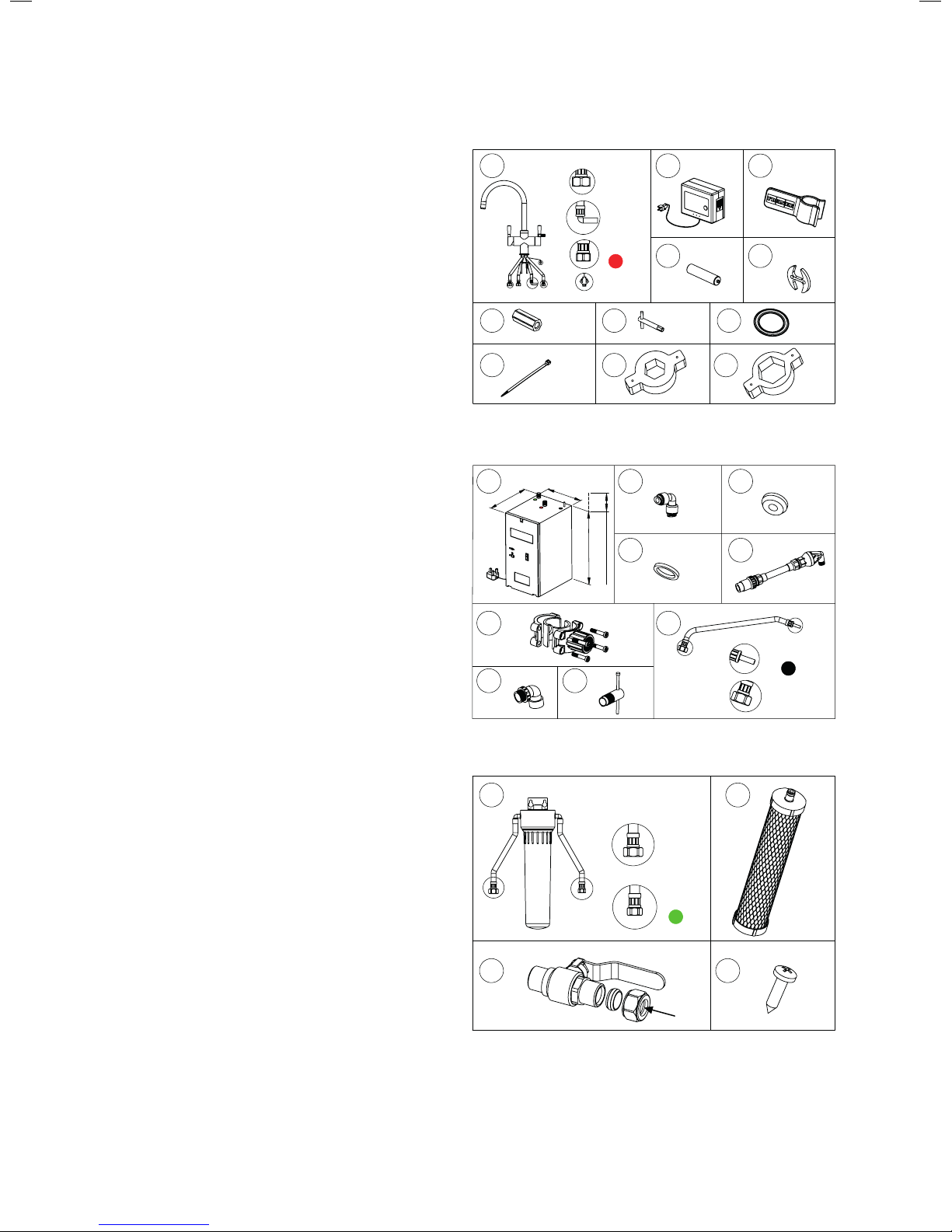

Boiler technical data

Description Value Unit

Dimensions 230 x 182 x 354 mm

Load 10 Amps

Voltage 230 Volts

Power 1500 Watts

Stored Temperature 105 °C

Min Water Pressure 1.5 Bar

Max Water Pressure 5 Bar

Heating Up Time 20 Mins

Recovery Time 10 Mins

Boiler Capacity 4 Litres

Pressure Release Valve Rating 8 Bar

Before you begin

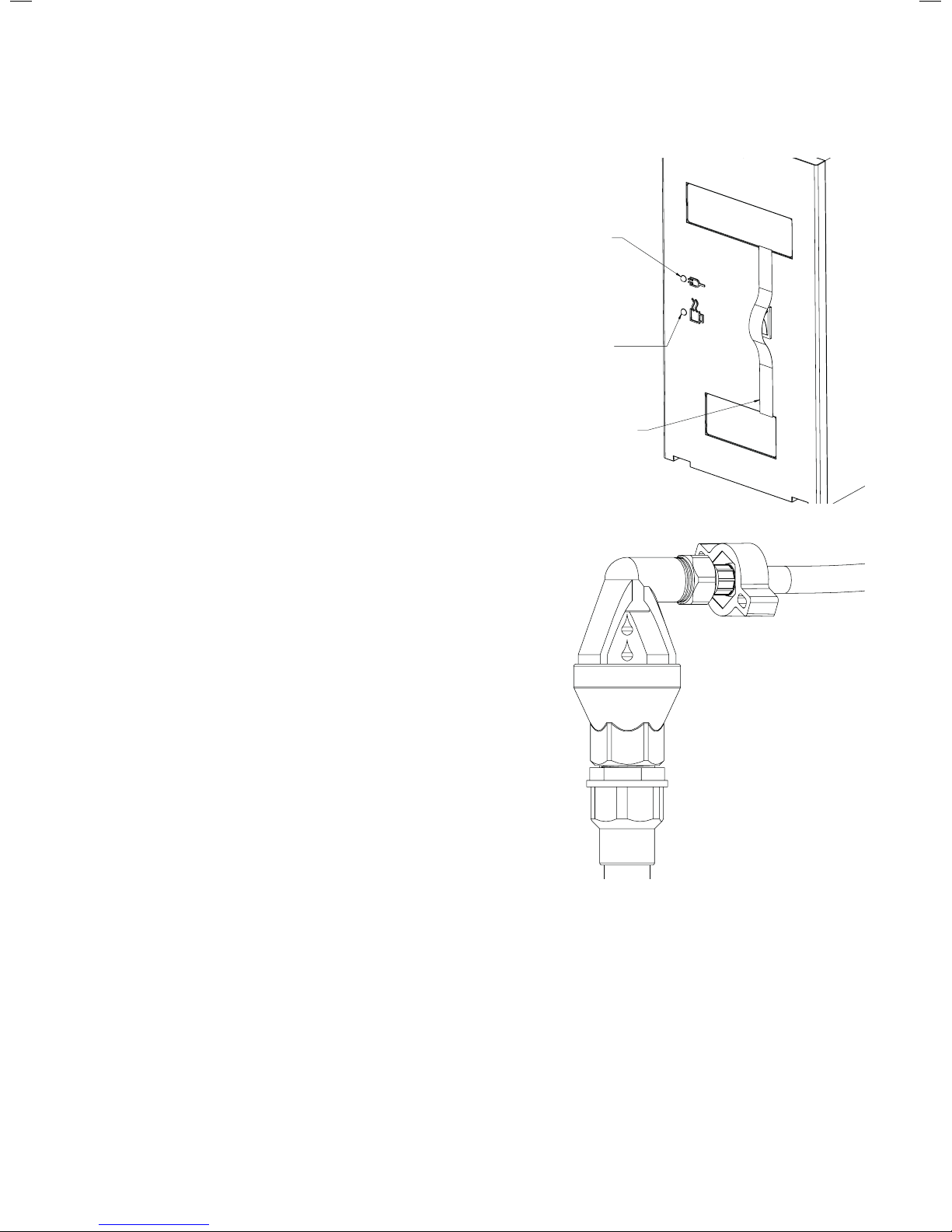

1. Check the mains water pressure. The pressure must not

be below 1.5 BAR (22 psi) or above 5 BAR (73psi),

measured during a low demand period – (mid-morning or

mid-afternoon). If the pressure exceeds 5 BAR a pressure

reducing valve must be installed in the cold mains supply

to protect both the boiler and the water filter housing. A

suitable pressure reducing valve can be purchased at

www.frankefilterflow.co.uk.

2. The unit must be installed in a frost free environment.

3. Ensure that the cabinet is well ventilated. If in doubt it is

advisable to improve the circulation of air by drilling some

holes in the top and bottom of the rear panel.

4. Be careful when making the various connections to the

mains water stop valve and the boiler. Do not be tempted

to over-tighten the connections. It is only necessary to

firmly hand tighten the nuts using the patented

NutRunna®plastic tightening devices provided to make a

secure watertight seal.

5. Locate the existing hot and cold water supply pipes.

6. Shut off the mains water supply.

7. Switch off the mains electricity supply at the socket.

Safety

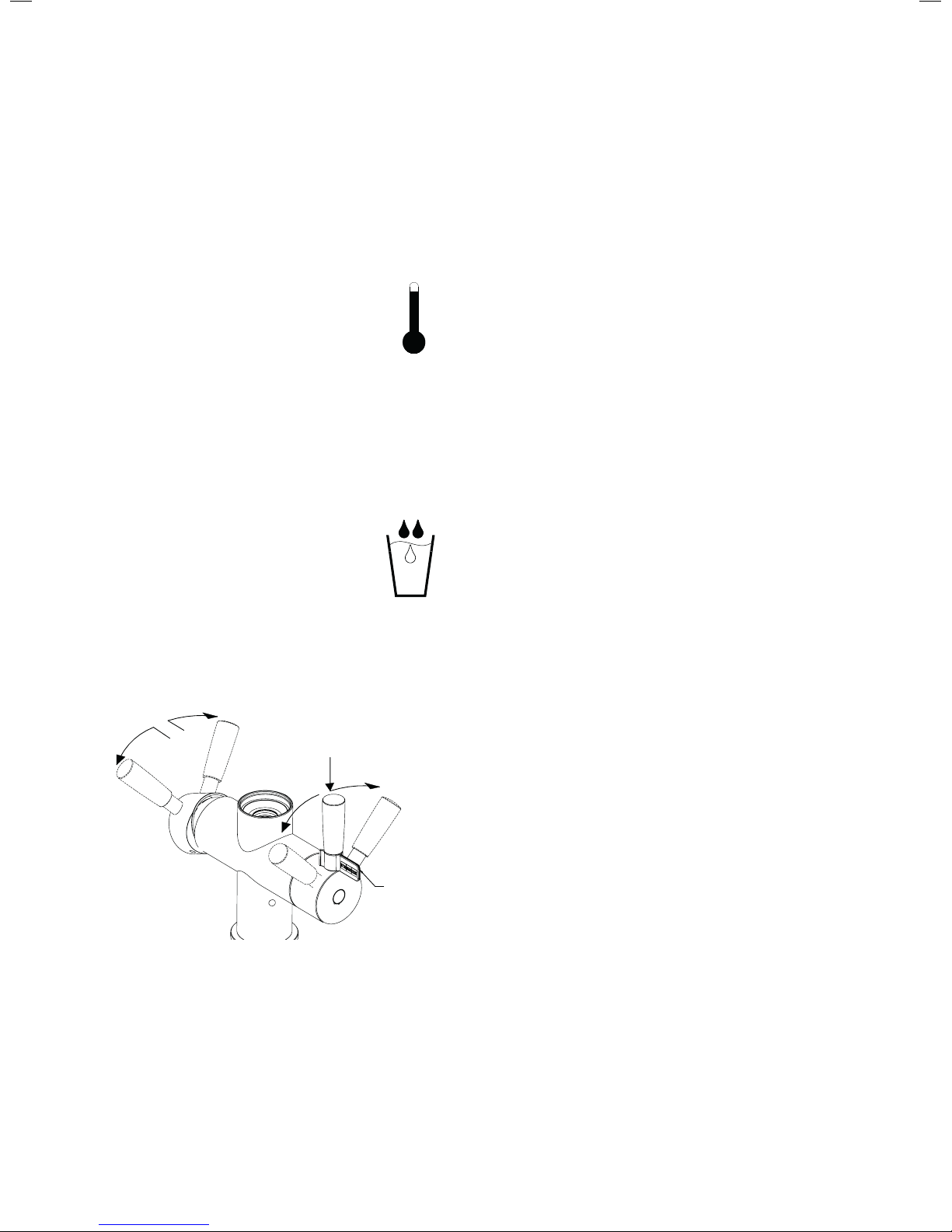

Remember: Boiling water is potentially dangerous and great

care should be exercised when using the Franke Omni tap.

The installation must be carried out by a suitably qualified

professional in strict accordance with the instructions

provided and comply with the UK Water Supply (Water

Fittings) Regulations 1999 and safety standards.

• If a new electrical power supply is required you must

seek the services of a qualified electrician.

• The boiler must only be connected to the 230V mains

electricity supply through either an earthed independent

wall socket or a fused spur.

• The boiler is fitted with an electrical lead terminating in

a UK 3 pin fused plug for connection to the 230 volt 13

amp domestic electricity supply. It is important to use a

socket with a built in switch and position it to provide

convenient access to switch off the boiler.

• Turn off the mains water supply before commencing

installation.

• Never lift the boiler by the flexible connector hoses.

• The power to the boiler must only be switched on once

the installation is complete and the tank is full of water.

• Always turn off the electricity supply to the boiler before

you close the mains stop valve. Restore power to the

boiler after the mains stop valve has been opened.

• Young people and potentially vulnerable users must

be instructed how to operate the boiling water function

safely by a responsible adult.

• This is a domestic appliance and must not be installed in

a commercial environment.

• If the supply cord is damaged it must be replaced by

the manufacturer, an official service agent or similarly

qualified persons in order to avoid a hazard.