RKC INSTRUMENT SR Mini HG SYSTEM H-LNK-A User manual

SR Mini HG SYSTEM

IMSRM52-E4

Power Supply/CPU Module

Link Module

[Control & Communication Link]

H

-

PCP

-

G

H-LNK-

A

Instruction Manual

RKC INSTRUMENT INC.

®

All Rights Reserved, Copyright 1998, RKC INSTRUMENT INC.

.

The MELSEC and Control & Communication Link system are products manufactured by Mitsubishi

Electric Co., Ltd.

Company names and product names used in this manual are the trademarks or registered trademarks of

the respective companies.

IMSRM52-E4 i-1

Thank you for purchasing the RKC instrument. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place this manual in a convenient location for easy reference.

SYMBOLS

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

: This mark indicates where additional information may be located.

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

CAUTION

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are no

t

taken, damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

WARNING

!

WARNING

!

IMSRM52-E4

i-2

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take adequate measures.

This instrument is protected from electric shock by reinforced insulation. Provide reinforced

insulation between the wire for the input signal and the wires for instrument power supply,

source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the instrument or

equipment.

All wiring must be in accordance with local codes and regulations.

All wiring must be completed before power is turned on to prevent electric shock, instrument

failure, or incorrect action.

The power must be turned off before repairing work for input break and output failure including

replacement of sensor, contactor or SSR, and all wiring must be completed before power is

turned on again.

To prevent instrument damage or failure, protect the power line and the input/output lines from

high currents with a protection device such as fuse, circuit breaker, etc.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric shock,

fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

Do not connect modular connectors to telephone line.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from the use of instruments made by

imitating this instrument.

Periodic maintenance is required for safe and proper operation of this instrument. Some components

have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in this

manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior written

approval from RKC.

CAUTION

IMSRM52-E4 i-3

CONTENTS

Page

1. OUTLINE............................................................................... 1

1.1 Product Outline................................................................................................1

1.2 Handling Procedure.........................................................................................2

1.3 Checking the Products ....................................................................................3

1.4 Confirmation of the Model Code ......................................................................4

1.5 System Configuration ......................................................................................5

1.6 Parts Description .............................................................................................7

1.6.1 H-PCP-G module ................................................................................................. 7

1.6.2 H-LNK-A module .................................................................................................. 8

2. SPECIFICATIONS .............................................................. 10

2.1 H-PCP-G Module...........................................................................................10

2.2 H-LNK-A Module ...........................................................................................13

3. MOUNTING ......................................................................... 15

3.1 Mounting Environment...................................................................................15

3.2 Dimensions....................................................................................................16

3.3 Mounting the Mother Block............................................................................18

3.4 Mounting the Module .....................................................................................20

3.5 Removing the Module....................................................................................21

3.6 How to Fix the Terminal Cover ......................................................................22

4. WIRING ............................................................................... 23

4.1 Wiring of H-PCP-G Module............................................................................23

4.2 Connection of H-LNK-A Module With Master Station ....................................26

5. PREPARATION BEFORE OPERATION .......................... 28

5.1 Station No. Setting.........................................................................................28

5.2 Transmission Speed Setting..........................................................................29

5.3 Host Communication and Unit Address Settings ...........................................30

IMSRM52-E4

i-4

Page

5.4 When the Power is Turned on for the First Time ...........................................31

5.5 Control Unit Operation When the PLC is Abnormal.......................................31

6. REMOTE INPUT/OUTPUT AND REMOTE REGISTERS .. 32

6.1 Communication Between Master Station and Remote Device Station ..........32

6.2 Remote Input/Output .....................................................................................33

6.3 Remote Registers..........................................................................................43

6.4 Extension No. ................................................................................................45

6.5 Flag Operation...............................................................................................51

7. EXAMPLES OF SEQUENCE PROGRAMS ....................... 54

7.1 List of Internal Relays (M) and Data Registers (D) ........................................55

7.2 Example of Initialize Sequence Program.......................................................60

7.3 Example of Data Fetch Sequence Program ..................................................61

7.4 Example of Set Data Change Sequence Program ........................................62

8. HOST COMMUNICATION .................................................. 63

IMSRM52-E4 1

1. OUTLINE

1.1 Product Outline

The control unit for the SR Mini HG SYSTEM can easily configure a temperature control/monitoring

system on Control & Communication Link by connecting it with Control & Communication Link.

In addition, the control unit for the SR Mini HG SYSTEM correspond to Control & Communication

Link Ver. 1.10.

Control & Communication Link: Mitsubishi Electric field network

The control unit for the SR Mini HG SYSTEM consists of the dedicated power supply/CPU module

(H-PCP-G), the Link module (H-LNK-A) and temperature control function modules.

This manual describes the specifications, mounting and wiring of the power supply/CPU module

(H-PCP-G) and the Link module (H-LNK-A) and also data on the SR Mini HG SYSTEM processed

by the Control & Communication Link system.

Connected to

Control &

Communication

Link

Up to 8 temperature control

function modules can be

connected.

Power supply/CPU module,

H-PCP-G

Link module,

H-LNK-A

RS-232C or

RS-422A

(RKC standard

protocol)

SR Mini HG SYSTEM control unit

(Remote device station)

1. OUTLINE

IMSRM52-E4

2

1.2 Handling Procedure

Proceed with the work according to the following procedure.

When conducting the mounting and wiring, station No. and transmission speed settings

and programming, always read and follow the manual for Mitsubishi's PLC described

in the following:

User's manual for Control & Communication Link system master/local unit,

Mitsubishi Electric Co., Ltd.

Confirmation of the products

Confirmation of the model code

See 1.3 Checking the Products (P. 3).

See 1.4 Confirmation of the Model Code (P. 4).

Mounting and Wiring

See 3. MOUNTING (P. 15).

See 4. WIRING (P. 23).

Station No. and transmission

speed settings

See 5.1 Station No. Setting (P. 28).

See 5.2 Transmission Speed Setting (P. 29).

Programming

See 7. EXAMPLE OF SEQUENCE PROGRAMS

(P. 54).

Turn on the power

See 5.4 When the Power is Turned on for the First

Time (P. 31).

Operations

1. OUTLINE

IMSRM52-E4 3

1.3 Checking the Products

When unpacking your new instrument, please confirm that the following products are included. If any

of the products are missing, damaged, or if your manual is incomplete, please contact RKC sales office

or agent for replacement.

H-PCP-G module (Power supply/CPU module).......... 1 module

One H-PCP-H module (power supply/CPU module) is required for each control unit.

H-LNK-A module (Link module) .................................. 1 module

One H-LNK-A module (Link module) is required for one control unit.

Function modules .............. Required number of modules

Reference purchase order for description of function modules.

DIN rail holding clips.......... Two clips per unit

Control & Communication Link

H-PCP-G/H-LNK-A Instruction Manual (IMSRM52-E) ......1 copy

Hardware Quick Manual (IMS01V01-E).............................1 copy

Communications Quick Manual (IMS01V02-E) ................1 copy

1. OUTLINE

IMSRM52-E4

4

1.4 Confirmation of the Model Code

The model code for the instrument you received is listed below. Please confirm that you have received

the correct instrument by checking the model code label, located on the left side of the module, with

this list. If the product you received is not the one ordered, please contact RKC sales office or agent

for replacement.

The Model code label is attached to the left side of the module.

H-PCP-G module (Power supply/CPU module)

(1) Type

G: Type dedicated to Control & Communication

Link (DO: 4 points)

(2) Power supply voltage

3: 24 V DC

(3) Communication interface

1: RS-232C

4: RS-422A

(4) External connector

N: No function

Alarm Code Table

The selected function will be common for all the modules with alarm functions in the control unit.

H-LNK-A module (Link module)

(1) Type

A: Control & Communication Link connection function type

H-LNK- A

(1)

H-PCP- G - 3 N - ∗

(1) (2) (3) (4) (5) (6) (7)

A: Deviation High B: Deviation Low

C: Deviation High and Low D: Deviation Band

E: Deviation High (with alarm hold) F: Deviation Low (with alarm hold)

G: Deviation High and Low (with alarm hold) H: Process High

J: Process Low K: Process High (with alarm hold)

L: Process Low (with alarm hold)

A special alarm function

Q: Deviation High (with alarm re-hold) R: Deviation Low (with alarm re-hold)

T: Deviation High and Low (with alarm re-hold)

(5) DO signal

M: Relay contact output

D: Open collector output

(6) First alarm function

N: No alarm function

: See Alarm Code Table

(7) Second alarm function

N: No alarm function

: See Alarm Code Table

1. OUTLINE

IMSRM52-E4 5

1.5 System Configuration

If the SR Mini HG SYSTEM control unit is connected to Control & Communication Link via the

H-LNK-A module (Link module), data on the SR Mini HG SYSTEM can be processed by the

programmable controller (Mitsubishi MELSEC: hereinafter, PLC). In addition, the SR Mini HG

SYSTEM control unit is connected to Control & Communication Link as a remote device station.

When only the SR Mini HG SYSTEM control units are connected to Control &

Communication Link: Up to 16 units.

Up to 64 stations (Up to 16 units)

When the host computer is connected:

Up to 16 units (Only when RS-422A is

SR Mini HG SYSTEM control unit

Control &

Communication

Link

Function modules,

Up to 8 modules

Mitsubishi PLC

SR Mini HG SYSTEM control unit

H-PCP-G

Host

computer H-LNK-

A

Master station

RS-232C/RS-422

A (RKC standard

protocol)

RS-422A

(RKC standard

protocol)

RS-422A

(RKC standard

protocol)

RS-232C/

RS-422A

(dedicate

d

The SR Mini HG

SYSTEM can be set

and monitored.

Both PLC and SR Mini HG

SYSTEM can be set and

monitored.

Operation panel, OPC-H

Function modules,

Up to 8 modules H-LNK-

A

H-PCP-G

1. OUTLINE

IMSRM52-E4

6

Usable modules

The following function modules can be used with Control & Communication Link in combination

with the H-PCP-G and H-LNK-A modules.

Temperature control module

H-TIO-A ··············· 1 channel type, Temperature input

H-TIO-B ··············· 2 channels type, Temperature input

H-TIO-C ··············· 1 channel heat/cool type, Temperature input

H-TIO-D ··············· 2 channels heat/cool type, Temperature input

H-TIO-E ··············· 1 channel type, High accuracy temperature input

H-TIO-F ··············· 2 channels type, High accuracy temperature input

H-TIO-G··············· 1 channel heat/cool type, High accuracy temperature input

H-TIO-H ··············· 1 channel type, Continuous voltage/current input

H-TIO-J ·············· 2 channels type, Continuous voltage/current input

H-TIO-R ··············· 1 channel type with fuzzy function, Temperature input

H-TIO-P ··············· 2 channels type with fuzzy function, Temperature input

The current transformer (CT) input function built in the temperature control modules

(H-TIO-A/C/D) cannot be used.

Current transformer input module

H-CT-A ·················· CT input 6 points type (Each 2 points together are common)

For details of the temperature control modules and current transformer modules, see the

separate Hardware Quick Manual (IMS01V01-E).

Maximum No. of channels, modules or units when connected to Control &

Communication Link

Maximum number of control channels that can be connected to one control unit:

16 channels/control unit

256 channels/system (Only when the SR Mini HG SYSTEM is connected)

No. of function modules which can be connected to one control unit:

8 modules (excluding the H-PCP-G and H-LNK-A modules)/control unit

The maximum number of channels cannot be selected for the temperature control,

temperature input or current transformer input modules as the number of function

modules per control unit is limited to 10.

No. of control units which can be connected to Control & Communication Link:

16 units/system (Only when the SR Mini HG SYSTEM is connected)

1. OUTLINE

IMSRM52-E4 7

1.6 Parts Description

1.6.1 H-PCP-G module

No. Name Description

(1) Unit address No. setting switch Switch to set control unite address No.

Setting range: 0 to 15 (0 to F, hexadecimal)

(2) Data correctly received indicator

lamp (RX), Yellow LED

Turned on: During data receive

(3) Data correctly sent indicator

lamp (TX), Yellow LED

Turned on: During data send

(4) Failure indicator lamp (FAIL),

Red LED

Turned off: When the module is normal

Turned on: When the module is abnormal

(5) Operation indicator lamp (RUN),

Green LED

Flashing: The module operates normally.

(6) Modular connector 1 Connector for connection with the host computer

Conforming to RS-232C or RS-422A

(7) Modular connector 2 Extended link connector

Conforming to RS-422A

(8) Terminals Power supply/ground/FAIL output/digital output

terminals

(9) Mother block Module connection base block

(10) Module connection connector Power supply and internal bus connection connector

(10)

(9)

Side

(1) (2)

(6)

(8)

(7)

(5)

(4)

(3)

Front

1. OUTLINE

IMSRM52-E4

8

1.6.2 H-LNK-A module

No. Name Description

(1) Data correctly received indicator

lamp (RX), Yellow LED

Turned on: During data receive

(2) Data correctly sent indicator

lamp (TX), Yellow LED

Turned on: During data send

(3) Failure indicator lamp (FAIL),

Red LED

Turned off: When the module is normal

Turned on: When the module is abnormal

Flashing 2: Transmission speed setting or station

setting error now occurs.

At intervals of 0.5 sec (OFF for 0.25

sec/ON for 0.25 sec)

(4) Operation indicator lamp (RUN),

Green LED

Turned on: H-LNK-A module is not identified by

H-PCP-G module or H-LNK-A module

is being initialized.

Flashing 1: The module operates normally.

At intervals of 1 sec (OFF for 0.5 sec/ON

for 0.5 sec)

Flashing 2: −The transmission speed setting or

station No. setting switch was

changed during operation.

−CRC error now occurs.

At intervals of 0.5 sec (OFF for 0.25

sec/ON for 0.25 sec)

Continued on the next page.

(6)

(7)

(9)

(8)

(5)

(1) (2)

(3)

(4)

Rear

(View with the mother block removed)

Side

Front

1. OUTLINE

IMSRM52-E4 9

Continued from the previous page.

No. Name Description

(5) Station No. setting switch

(STATION No.)

×10: For tens digit setting

×1: For unit digit setting

Switch to set control unit station No.

Setting range: 1 to 61

(6) Communication terminals Control & Communication Link connection

terminals

(7) Transmission speed setting

switch

Switch to set the transmission speed of the control

unit and Control & Communication Link master

station

Setting range: 0 to 4

0: 156 Kbps

1: 625 Kbps

2: 2.5 Mbps

3: 5 Mbps

4: 10 Mbps

5 to 9: Setting inhibited

(8) Mother block Module connection base block

(9) Module connection connector Power supply and internal bus connection connector

10 IMSRM52-E4

2. SPECIFICATIONS

2.1 H-PCP-G Module

(1) Basic functions

Item Specifications

Data supervision function Operating data/system data

Unit diagnosis function Function modules configuration check

Self-diagnostic function Check item ROM/RAM check

Watchdog timer

CPU power supply monitoring

Operation at error

occurrence in

self-diagnosis

All module outputs are set to the off state

hardware wise.

Memory backup function RAM is backed up by lithium battery.

Data retaining time: Approx. 10 years

(Time integrated during power off)

Control & Communication

Link connectable modules

H-TIO-A/B/C/D/E/F/G/H/J/P/R

H-CT-A

H-LNK-A

Number of temperature control channels:

Up to 16 channels/control unit

Number of connectable modules: 8 modules/control unit

(Excluding H-LNK-A)

Operation after power on Start-up from control STOP condition (Factory set value)

Can be changed by the host computer communication setting

(Initialize setting).

(2) Power input

Item Specifications

Power supply voltage Rating: 24 V DC

Range of power supply

voltage

21.6 to 26.4 V DC

Power consumption 20 W max.

Surge current 30 A or less

(3) Power output (Function module power)

Item Specifications

Output voltage/current 5 V DC, 1.6 A max.

12 V DC, 1.0 A max.

Overcurrent protection Fold-back limiting method: 5V

2. SPECIFICATIONS

IMSRM52-E4 11

(4) Output

Item Specifications

FAIL output Relay contact output

Number of output points: 1 point

Rating: 250 V AC, 0.1 A (Resistive load)

Electrical life: 300,000 time or more (Rated load)

Contact type: 1a contact

Failure action: Open at error occurrence

Digital output Relay contact output

Number of output points: 4 point

Rating: 250 V AC, 1 A (Resistive load)

Electrical life: 300,000 time or more (Rated load)

Contact type: 1a contact

Open collector output

Number of output points: 4 points

Rating: 12 to 24 V DC

Maximum load current: 0.1 A/point, 0.8 A/common

Specify either relay contact output or open-collector output when

ordering.

Digital output can be selected from among the following outputs.

− Temperature alarm (First alarm, Second alarm)

− Heater break alarm (HBA)

− Burnout alarm

− Loop break alarm (LBA)

− Temp. rise completion

(5) Interface (RKC standard communication)

Item Specifications

Communication interface Based on RS-422A, EIA standard

Based on RS-232C, EIA standard

Specify when ordering

Communication method 4-wire system, multi-drop connection (RS-422A)

Point-to-point connection (RS-232C)

Protocol Based on ANSI X 3.28 subcategory 2.5, B1

Synchronous method Start-stop synchronous type

Communication speed 2400 bps,4800 bps,9600 bps,19200 bps

Any can be selected.

Data bit configuration Start bit: 1

Data bit: 7 or 8

Parity bit: Without, Odd or Even (For 8 data bits: Without)

Stop bit: 1

Error control Vertical parity (When parity bit is selected)

Horizontal parity

Data types ASCII code

2. SPECIFICATIONS

IMSRM52-E4

12

(6) System setting items

Item Specifications

Temperature alarm First alarm and Second alarm

− Deviation high alarm

− Deviation low alarm

− Deviation high/low alarm

− Band alarm

− Deviation high alarm with hold action

− Deviation low alarm with hold action

− Deviation high/low alarm with hold action

− Process high alarm

− Process low alarm

− Process high alarm with hold action

− Process low alarm with hold action

− Deviation high alarm with re-hold action

− Deviation low alarm with re-hold action

− Deviation high/low alarm with re-hold action

Specify either the 1st alarm or 2nd alarm function when ordering.

The specified function is common to all of the modules with the

alarm function within the control unit.

Temperature rise

completion function

Completion trigger range: ±1 to ±10 °C (20 °F)

(Value from main set value)

Temperature rise completion soak time: 0 to 360 minute

Temperature rise completion trigger function can be selected for

each channel.

(7) LED display

Item Specifications

RUN lamp Green LED

Flashing: The module operates normally.

FAIL lamp Red LED

Turned off: When the module is normal

Turned on: When the module is abnormal

TX lamp Yellow LED

Turned on: During data send

RX lamp Yellow LED

Turned on: During data receive

(8) General specifications

Item Specifications

Dimensions 48(W) ×96(H) ×100(D) mm

Weight 320 g

2. SPECIFICATIONS

IMSRM52-E4 13

2.2 H-LNK-A Module

Item Specifications

Module type Remote device station

No. of occupied stations 4 stations occupied

Transmission speed 0: 156 Kbps

1: 625 Kbps

2: 2.5 Mbps

3: 5 Mbps

4: 10 Mbps

Set by the rotary switch at the rear of the module.

The maximum transmission distance differs depending on the

transmission speed.

Maximum transmission

distance

156 Kbps: 1200 m

625 Kbps: 900 m

2.5 Mbps: 400 m

5 Mbps: 160 m

10 Mbps: 100 m

Distance between stations 0.2 m or more

Station No. setting 1 to 61 (Setting other than this setting causes error.)

Set by the rotary switch at the front of the module.

LED display RUN lamp

Green LED

Turned on: H-LNK-A module is not identified by

H-PCP-G module or H-LNK-A

module is being initialized.

Flashing 1: The module operates normally.

At intervals of 1 sec (OFF for 0.5

sec/ON for 0.5 sec)

Flashing 2: −The transmission speed setting or

station No. setting switch was

changed during operation.

−CRC error now occurs.

At intervals of 0.5 sec (OFF for 0.25

sec/ON for 0.25 sec)

LED display FAIL lamp Red LED

Turned off: When the module is normal

Turned on: When the module is abnormal

Flashing 2: Transmission speed setting or station

setting error now occurs.

At intervals of 0.5 sec (OFF for 0.25

sec/ON for 0.25 sec)

TX lamp Yellow LED

Turned on: During data send

RX lamp Yellow LED

Turned on: During data receive

Continued on the next page.

2. SPECIFICATIONS

IMSRM52-E4

14

Continued from the previous page.

Item Specifications

Communication items Remote relay

− First alarm status

− Second alarm status

− Burnout alarm status

− Heater break alarm (HBA) status

− PID/AT transfer status

− Control RUN/STOP transfer

Remote registers (Read only)

− Temperature measured value (PV)

− Manipulated output (Heat-side)

− Manipulated output (Cool-side)

− CT input measured value

− Control RUN/STOP status

− Decimal-point position

− Set value monitoring

− Control loop break alarm (LBA) status

− Error code

Remote registers (Common to read and write)

− Temperature set value (SV)

− PID/AT transfer

− Proportional band (Heat-side)

− Proportional band (Cool-side)

− Integral Time

− Derivative Time

− Control response designation parameters

− PV bias

Communication items Remote registers (Common to read and write)

− First alarm set value

− Second alarm set value

− Proportioning cycle time (Heat-side)

− Proportioning cycle time (Cool-side)

− Overlap/Deadband

− Heater break alarm (HBA) set value

− Operation mode setting

− Memory area number

− Auto/Manual transfer

− Manual output value

− Loop break alarm (LBA) use selection

− LBA time setting

− LBA Deadband

No. of remote register

channels

0: 16 channels

1: 8 channels

Factory set value: 0

Can be changed by the host computer communication setting.

Current consumption 290 mA DC

Dimensions 24(W) ×96(H)×100(D) mm

Weight 200 g

This manual suits for next models

1

Table of contents

Other RKC INSTRUMENT Power Supply manuals

RKC INSTRUMENT

RKC INSTRUMENT SR Mini HG SYSTEM H-PCP-J User manual

RKC INSTRUMENT

RKC INSTRUMENT SR Mini HG SYSTEM H-PCP-J User manual

RKC INSTRUMENT

RKC INSTRUMENT SR Mini HG SYSTEM H-PCP-J User manual

RKC INSTRUMENT

RKC INSTRUMENT H-PCP-J User manual

RKC INSTRUMENT

RKC INSTRUMENT SR Mini HG SYSTEM H-PCP-J User manual

Popular Power Supply manuals by other brands

TekPower

TekPower TP-3005D user manual

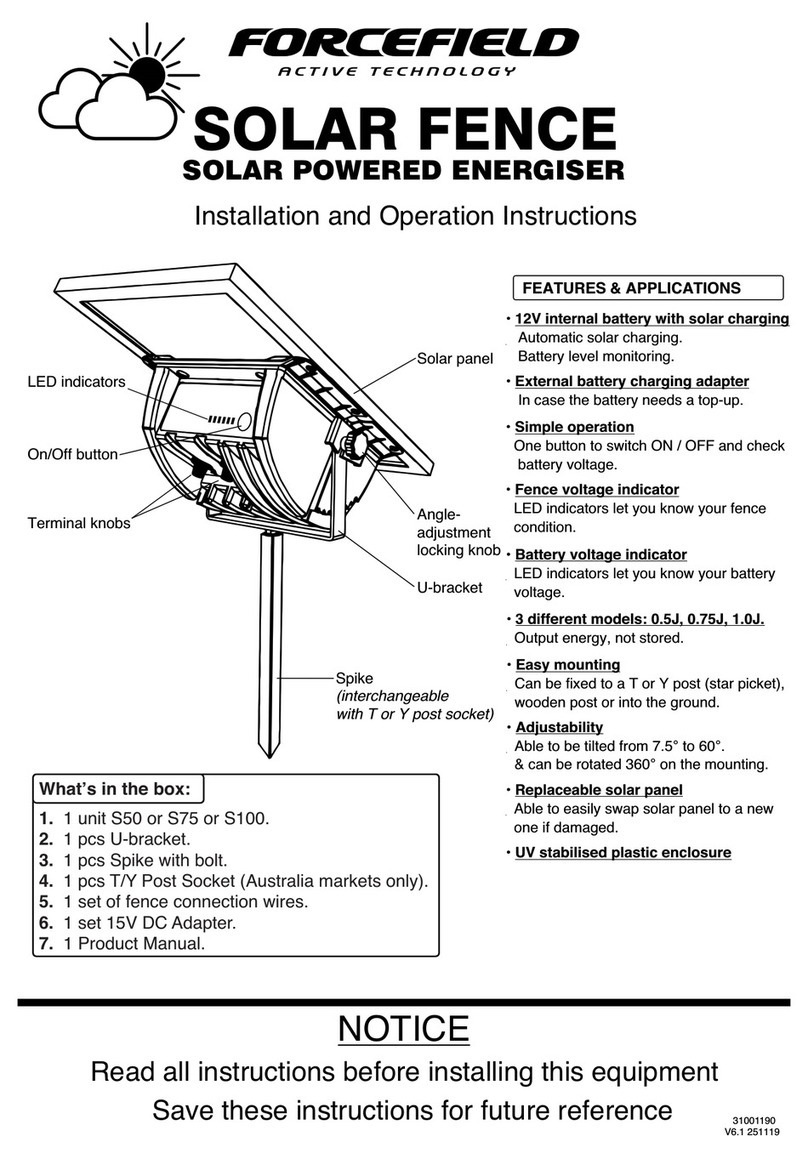

Forcefield

Forcefield SOLAR FENCE Installation and operation instructions

Monster

Monster PowerCenter HTUPS3700 owner's manual

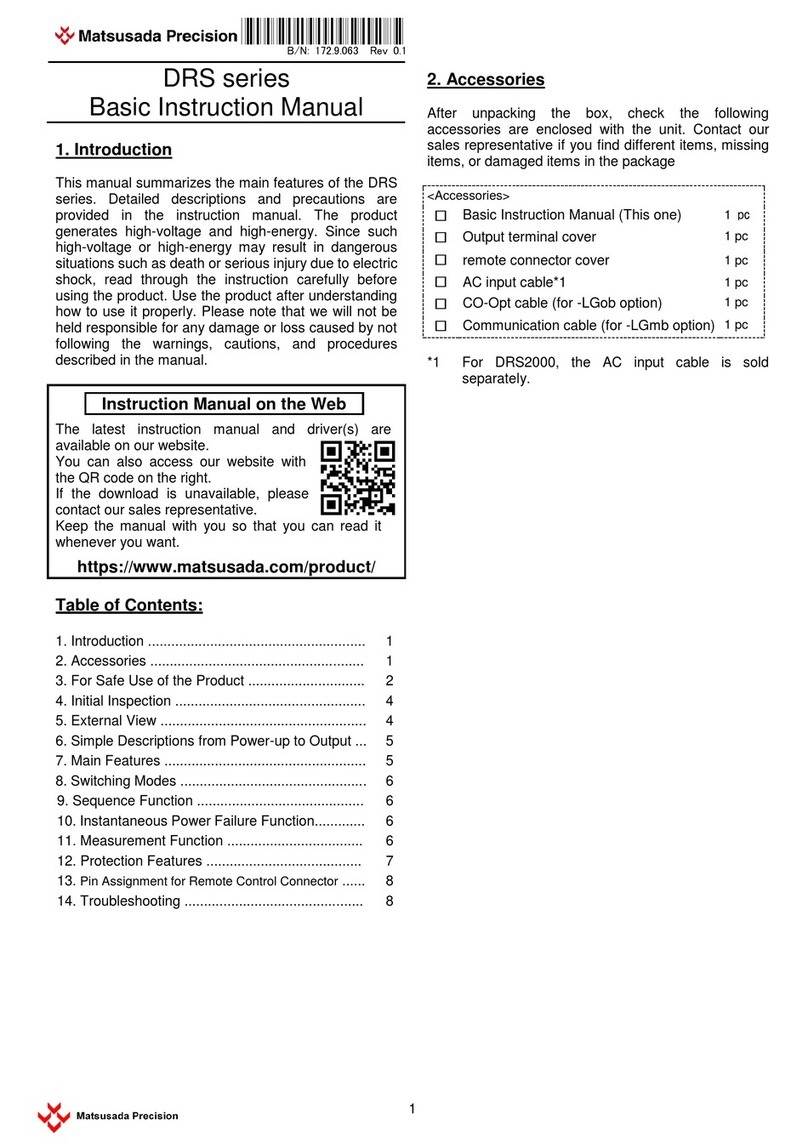

Matsusada Precision

Matsusada Precision DRS Series Basic instruction manual

Tesla

Tesla TI2500GPU-24 manual

Fractal design

Fractal design Integra R2 user manual