RM Solar Combi Konverter Solar System User manual

Installation Manual

Issue 1

Combi Konverter Solar System

These instructions are specic to the integration of the RMSolar Combi Konverter system with the combi

boiler. The RMSolar instructions should be used in terms of the overall solar installation. Particular

attention should also be paid to the cylinder instructions bearing in mind that the system uses an

unvented hot water storage cylinder which still has to meet Building Regulation Part G3 installation

requirements.

The basic principles of operation are as follows:-

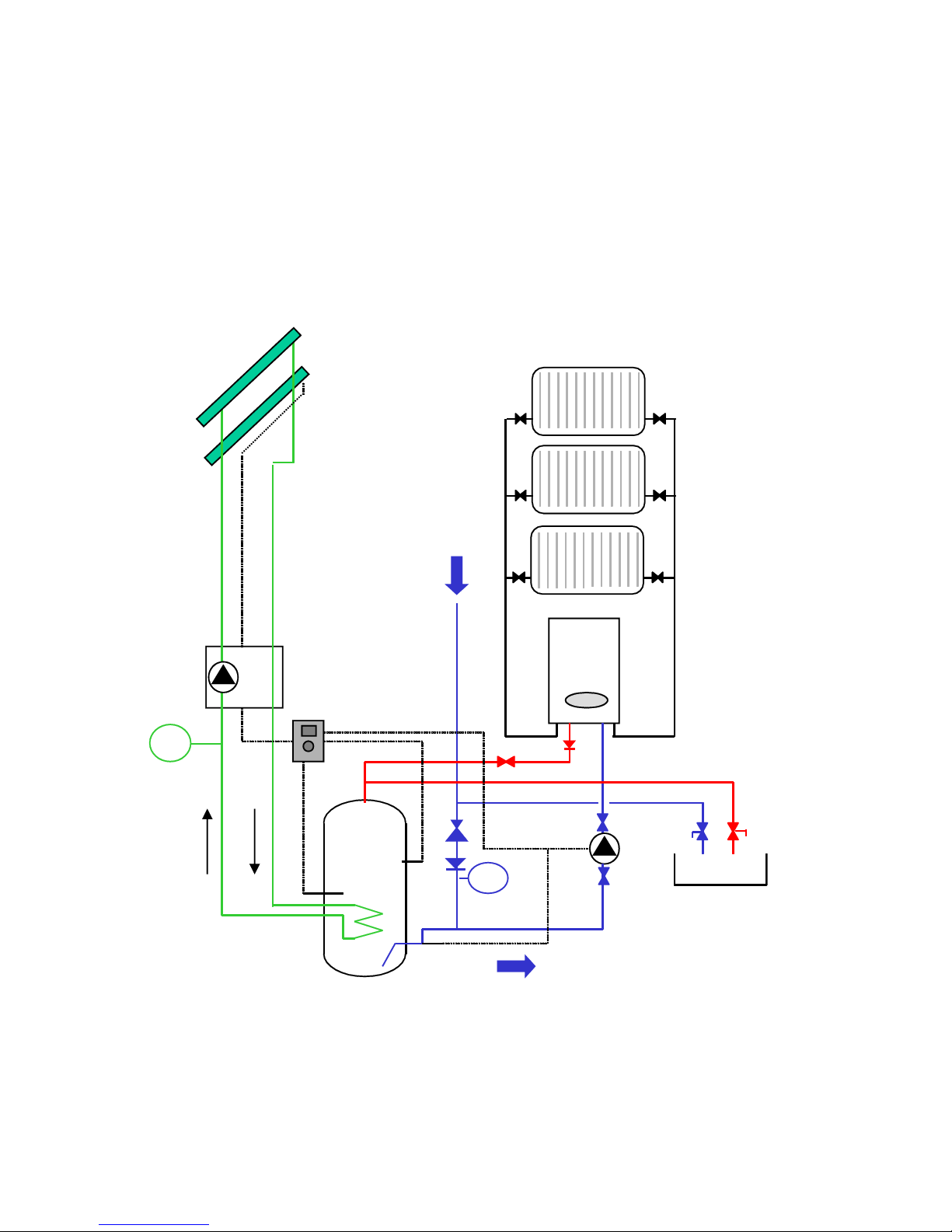

The system is shown schematically by Figs 1 and 2 using the high output domestic hot water output of

the combi to ‘charge up’ the top of the solar cylinder should insufcient solar heating be available.

Fig 1 General Schematic

In a conventional system a combi will re up on demand when it senses a ow to a hot water outlet.

In the Konverter system the combi will re up only in response to a ow through the appliance from a

circulation pump triggered by a cylinder sensor when the top of the cylinder is below a pre determined

temperature.

Panel/s

Solar

Pump

module

Combi

Taps

Cold

Feed

Radiators

Radiators

Radiators

Fig 2 Charging Sequence

Preparing for installation

The installation can be carried out by any competent person in accordance with the relevant building

regulations.

In order to properly commission the system the installer should be equipped with a suitable digital

thermometer to check ow temperatures. In most instances the combi boiler will already be in place thus

a route has to be found for additional pipe-work from the boiler to the hot water cylinder.

You will need to run two additional 22mm pipes from the boiler to the cylinder, one for the cold water feed

and one for the hot water draw off. The 22mm pipe that is allocated to the hot water draw off needs to be

adequately insulated.

As the cylinder is unvented it can be sited virtually anywhere in the dwelling but bearing in mind the likely

position of the solar panels then an upstairs position will probably be favourite.

If the combi boiler was retrotted to replace an old vented hot water storage system then a suitable site

might be the old airing cupboard. As is the case with all unvented systems the provision of a suitable

route for the discharge pipe might be the over riding factoring determining the best position.

In order for the system to operate there has to be a ow and return circuit from the combi to the cylinder

and for optimum performance the hydraulic resistance of this circuit needs to be minimised . The

circulating pump is capable of overcoming a 6 metre head resistance but some of this will be needed to

overcome the hydraulic resistance of the combi itself. This proportion will vary from combi to combi and

needs to be checked by the installer. In some circumstances it may be necessary to order an additional

bronze circulator pump to overcome the hydraulic resistance.

Before contemplating an installation the installer should check that the combi boiler is capable of

providing domestic hot water at circa 60oC. This might mean operating the appliance at a reduced

ow rate and adjusting the external and internal controls (if possible). The combis instructions or

manufacturers data should also be checked to ensure that the combi will re under conditions of low ow

and pressures of down to 0.5 bar. Some manufactures provide conversion ‘packs’ for low water pressure

areas and one of these might be required in some circumstances, normally this simply means removing

a ow restrictor.

It is advised that provision is made for a manual isolating switch on the feed to the circulation pump. This

should ideally be supplemented by the time controller provided and thought should be given to the best

position for these devices.

Connections and Pipe work

Where the combi boiler and the cylinder are in fairly close proximity with less than 5 metres of total (ow

plus return) pipe run then 15 mm copper will normally sufce. Once the length exceed this it is generally

required to use 22mm pipe. The pipe work runs should be designed to minimise hydraulic losses with

swept bends etc preferred to elbows.

The hot side (ow) of the circuit should be adequately insulated to minimise any temperature drop

between the combi and the cylinder. The cold feed (return) side of the circuit from the cylinder to the

combi should not be insulated.

The circulation circuit contains domestic hot water which may carry large amounts of dissolved air

and care should be taken to eliminate the possibility of air traps with pipe-work running as far as

possible from the boiler to the cylinder in a horizontal or uphill manner. Where this is not possible then

consideration should be given to automatic air traps or air separation devices.

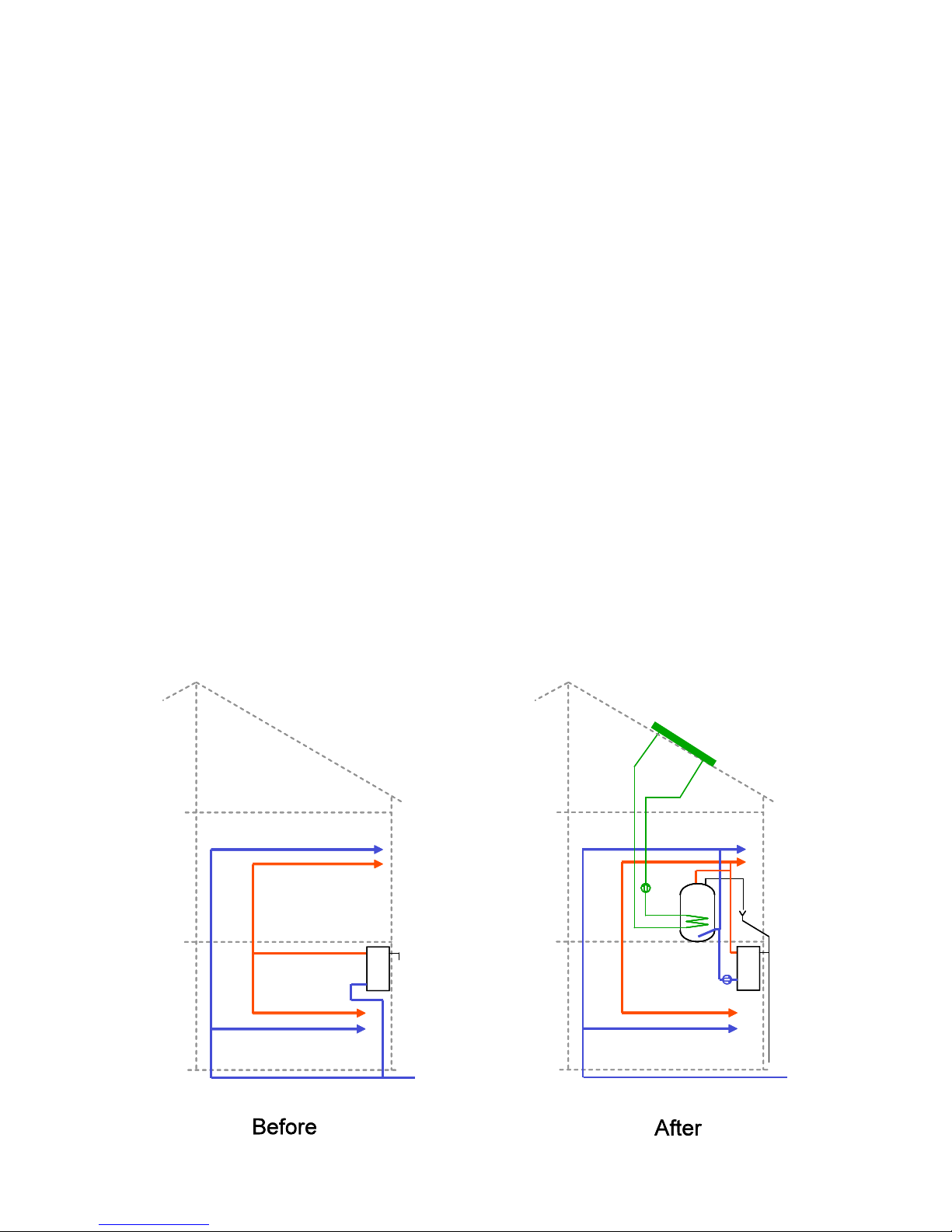

Fig 3 Typical Installation

Fig 4 Cylinder Connections

Hot Flow Pipe

The hot outlet from the Combi boiler should be piped directly to the cylinder hot draw off (there should be

no taps on this pipe that serve baths, basins, sinks ect), but should be tted with a suitable full ow gate

valve or similar so that if required the ow rate can be regulated as part of the commissioning process. In

circumstances where the combi is sited at a higher level than the cylinder then a non return valve should

be tted to the hot outlet where it exits the Combi boiler to prevent gravity circulation.

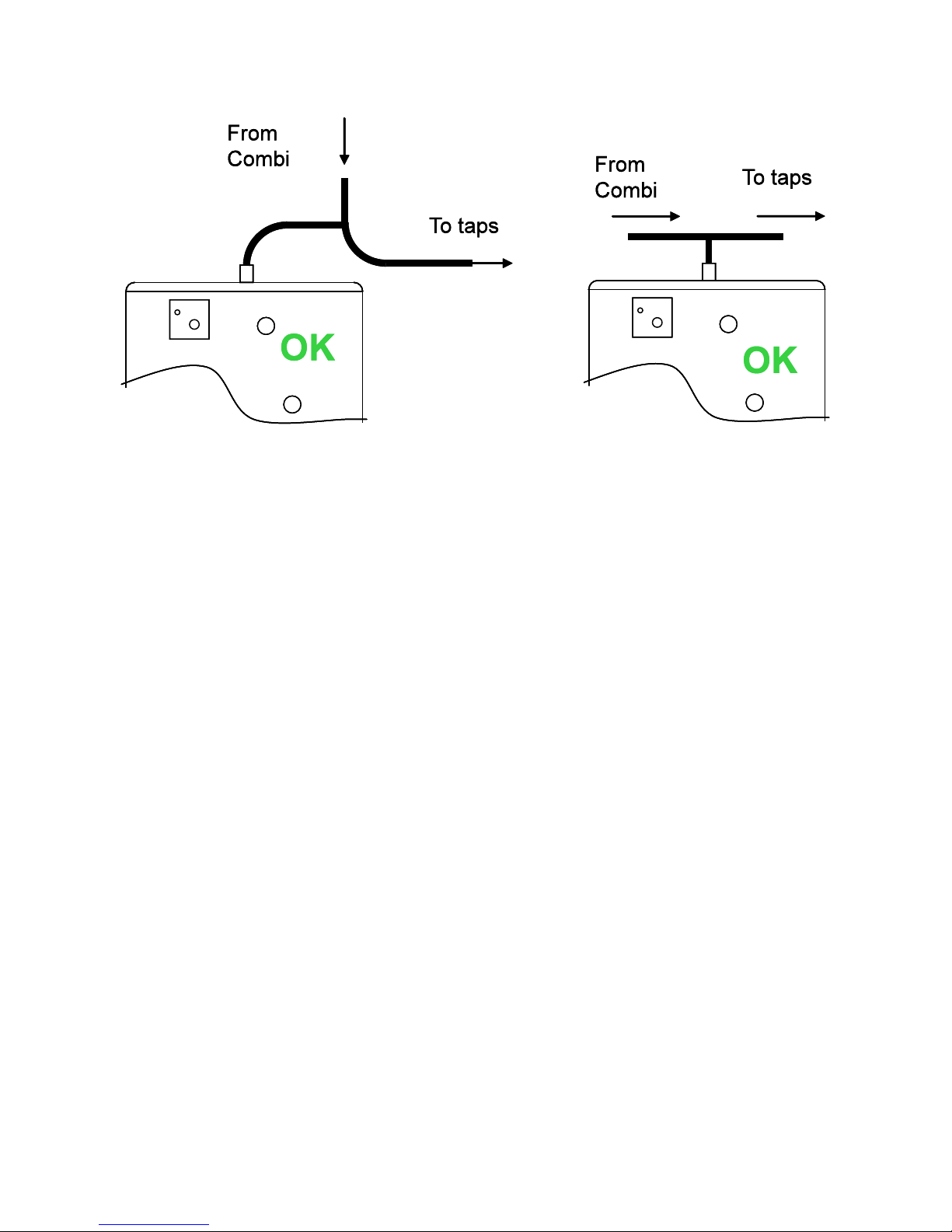

The hot water draw off at the cylinder should be tee’d into the hot water pipe coming from the Combi (as

shown in Fig 5) and then the outlets ( taps, showers ect,) connected down stream of the cylinder so that

now both the Combi and the cylinder can supply hot water on demand.

Fig 5

Cold Return Pipe

The mains cold feed needs disconnecting from the Combi boiler and a new cold feed given to the mains

pressure cylinder via the unvented inlet control set components.

(DO NOT use the 22mm pipe laid early, as instructed in Connections and Pipe work)

Connection at the cylinder should be made using the ½”x22x22mm compression tee (supplied). The

probe thermostat and pocket (supplied) are connected to this tee as illustrated. (See g 6).

Cut a Tee into the cold mains feed to the cylinder, (It is important that the Tee is connected at a point

between the unvented inlet control set components and ½”x22x22mm Tee cylinder connection see g

6) and now connect the 22mm pipe laid earlier (as instructed in connections and pipe work) to the spare

tapping on this Tee. (This pipe will be referred to as Combi cold feed from here onwards).

On the Combi cold feed pipe, install the Bronze pump and valves (supplied) with the pump ow pumping

to the Combi boiler.

Most installed combis are not tolerant to incoming ‘cold’ water temperatures of above 30oC but if in doubt

the Combi manufacturers advice on the maximum temperature should be sought . A limit thermostat (see

Fig 6) is tted on the cold feed to the cylinder, this can be set to the appropriate maximum temperature

(normally 30oC).

Where the combi is ‘solar compatible’ then this limit thermostat can be set at a higher temperature as

required.

Fig 6 Cold Inlet Thermostat

Circulation pump

The pump should always be sited with the motor spindle horizontal .Care should be taken to ensure

there is a minimum hydraulic restriction on the inlet side of the pump as this could cause a signicantly

reduced pressure zone thus encouraging dissolved air to cause pumping problems.

Wiring and Controls

The important points are as follows.

To meet G3 requirements the live feed to the solar controller circuit should be taken via the energy cut

out at the top of the cylinder.

The system should be tted with an isolating switch to disable the feed to the circulating pump, a timer is

also supplied, this should be tted in an area accesible to the end user.

Care should be taken to secure the sensors such that they can not slip out of the sensor pockets. This

can be achieved by means of a nylon tie or similar device (Fig 8)

Time switch In Series

with isolator

Fig 8 Sensor attachment

Commissioning

The important factor here is to ensure that the combi res in response to the circulation pump and

delivers water at a suitably high temperature circa 60oC.

The ow rate through the combi should be reduced to a level at which a 60oC charging temperature is

achievable. Too high a ow rate might also result in a high velocity stream of water entering the top of

the cylinder and destroying the stratication required to maintain the ‘hot top’.

In normal circumstances the pump speed should be set at either speed 2 or 3 but a certain amount of

ne tuning may be required to suit the particular installation.

The temperature setting for the combi circulation pump is achieved by programming the SHR controller

using the separate instructions provided and should be set such that the pump stops operating once it

senses water at 55oC at the upper sensor position .A digital thermometer with a thermocouple probe is

invaluable in setting up the system.

The cylinder is tted with a lower probe thermostat (g 6) which is set at the highest temperature

permitted by the combi manufacturer for cold water feed. This is typically 30oC but may be higher if the

combi is ‘solar-compatible’.

Setting the SHR controller

There are 3 settings that need to be changed in order for the system to operate correctly; -

Factory setting Re-set To

Arr - 1 2

AHO - 40.0 oC 50.0 oC

AHF - 45.0 oC 55.0 oC

Optional; -

S MX 60.0 oC Not above 75.0 oC

(S MX = The maximum store temperature achievable by solar input, if this is set above 60.0 oC then a

solar blending valve is strongly recommended on the cylinder hot outlet pipe).

Please adjust the settings in this order, see controller booklet for operating instructions.

Testing the system

Usually the hot water setting on the Combi needs to be set at maximum and the customer needs

informing that it needs leaving at this setting.

Take note of the temperature readings on the controller display panel, readings

TSTU and TSTL are the relevant ones.

When testing the system is operating correctly, sensor TSTU on the controller display (S3 g 4) should

gradually raise to 55.0 oC whilst the bronze pump and Combi boiler are running. This can take 10-

15mins depending on the boiler type. Once TSTU has reach 55.0 oC the boiler and pump will stop.

Open a hot tap and drain the cylinder until display TSTU reaches 50.0 oC then close the tap. The Combi

should re-start and continue to run until TSTU again achieves 55.0 oC then it should switch off.

Re-check the temperature of TSTL (S2 g 4), this reading should only have uctuated by 0-5 oC when

the ow rate from the bronze pump is set correctly. If the uctuation is greater that 5 oC then selecting a

lower pump speed on the Bronze pump and/or semi closing one of the Bronze pump gate valves (located

on the Combi cold feed pipe) will slow the ow rate and stop the problem. Re-test after making any

adjustments.

Hydraulic Balancing

As part of the commissioning process the installer should ensure that adequate hot temperature, albeit

at reduced ow rate, is provided from the Combi under conditions when the cylinder is depleted of hot

water. To ensure this, it is essential that the hydraulic resistance through the Combi circuit is such that

at the point where the ows from the cylinder and Combi combine, the Combi ow circuit will have

a sufcient pressure differential to prevent excessive cooling of the combined ow due to cold water

emerging from the cylinder

Handing over the system

Following commissioning it is important that the householder is made aware of the basic operation of the

system including the end user adjustable settings on the solar controller.

It should be explained to the householder that in situations where low levels of solar input coincide with a

high hot water demand such as bath lling, the hot water delivery characteristics will change signicantly

once the pre-charge of water from the cylinder is exhausted. Under these circumstances by reducing the

ow at the tap (semi-closing the tap) the water temperature will increase to a usable temperature.

Under these circumstances a continuous ow of hot water can still be maintained albeit at a reduced ow

rate.

Optional Blender

If the Combi is known to be solar compatible then an optional blender (see g 7) can be used with an

outlet temperature set to the maximum permissible inlet temperature of the Combi. This is connected

using the ‘spare’ 22mm male connection on the cylinder (see Fig 9).

Fig 9 – Optional Blender

The same option can also be used with most other combis provided the blender set outlet temperature

does not exceed 30oC.

RM Solar Ltd

Unit 4, Gilcar Way, Wakeeld Europort, Castleford WF10 5QS

Tel: 01924 224282 Fax: 01924 224283 Web: www.rmsolar.com

Popular Water Heater manuals by other brands

Vaughn

Vaughn Hydrastone ME Series Operation and installation manual

Rheem

Rheem MPi 551 Series Owner's guide and installation instructions

A.O. Smith

A.O. Smith GCV300 Service handbook

Atmor

Atmor Enjoy Installation and operation guide

Rinnai

Rinnai RV53E Operation and installation manual

Bradford White

Bradford White 203-B Specifications

EcoSpring

EcoSpring ES300 Installation & owner's manual

Aspes

Aspes ATE30S Instructions for use and maintenance

Dimplex

Dimplex Edel 200 WATER/3 installation manual

Watts

Watts Aerco INN 600N manual

Bosch

Bosch BH 120-5 Installation and maintenance instructions for the contractor

Enertech

Enertech WS036 Installation & operation manual