ROBAND F25E User manual

MANUFACTURED BY

ROBAND AUSTRALIA PTY LTD

OPERATING INSTRUCTIONS

DOUBLE PAN FRYERS

MODELS: F25, F25E, F28, & F28E.

Version 3

F25-UK

Version 1

Special Features:

Safety Over-Temperature Cutout as Standard

Advanced Control Safety Systems

Ultra-Durable Stainless Steel Elements

Superior Reliability & Longevity

These instructions cover the models of ROBAND®Double Pan Fryers

listed above. Although there are slight variances between models, the

installation, operation, care and maintenance procedure is the same for

all.

Page 2

Roband®

Roband Australia is a wholly Australian owned company and has been

manufacturing quality commercial catering equipment for the food service

industry for more than 50 years. Roband products are engineered and

manufactured to the highest standards to provide functionality, reliability

and durability, and our quality products are exported world-wide.

Included in the comprehensive ROBAND®range are Toasters, Fryers,

Milkshake Mixers, Rotisseries, Food Display Cabinets and much more.

Roband Australia also acts as the Australian agents for Vitamix®Blenders,

NOAW®Meat Slicers, RYNO Stainless Benching, RobalecTM Soup/Rice

warmers and Dito Food Processors.

In addition to a vast range of machines, Roband Australia has its own line

of commercial cookware and cutlery under the Robinox®brand name.

For a complete set of brochures please contact your nearest authorised

dealer or contact Roband directly at our head office.

Roband Australia Pty Ltd

11 Inman Road

DEE WHY

NSW 2099

Australia

Telephone: 61 – 2 – 9971 1788

Facsimile: 61 – 2 – 9971 1336

E-mail: [email protected]

Website: www.roband.com.au

For additional Agents in other

Countries please email Roband

Head office.

© Copyright 2000 – Roband Australia Pty Ltd

All rights reserved. No part of this work may be reproduced or copied in any form or by any means,

electronic or mechanical, including photocopying or posting to a website, without the written permission of

the publisher. The material contained within this document is intended entirely for instructional purposes.

International Agents

Canada: Lessard Agencies

Ph +1 416 766 2764

Europe: Valera Ltd, (UK) 0845 270 4321

Fiji: Hotel Equipment

Ph +679 672 0666

Hong Kong: Chung Wah

Ph +852 2334 5411

New Zealand: Roband New Zealand

Ph +649 274 1354

Papua New Guinea: Brian Bell

Ph +675 325 5411

Saudi Arabia: A S Al Jared Establishment

Ph +996 2 6451 451

Singapore: Jelco Private Ltd

Ph +65 5611 988

Thailand: Seven Five Distributors

Ph +662 866 5869

Page 3

CONTENTS

INTRODUCTION...........................................................................4

GENERAL PRECAUTIONS..........................................................4

PACKAGING.................................................................................5

COMPLIANCE ..............................................................................5

C-Tick:................................................................................................... 5

CE:........................................................................................................ 5

ACSS (Advance Control Safety System): ............................................. 5

INSTALLATION............................................................................6

OPERATION.................................................................................8

GENERAL SAFETY....................................................................10

SAFETY FEATURES.......................................................................... 10

GENERAL FIRE SAFETY................................................................... 10

CLEANING, CARE & MAINTENANCE ......................................11

TROUBLESHOOTING................................................................12

CIRCUIT DIAGRAM*.............................................................................. 13

Models F25, F25E, F28, F28E............................................................ 13

SPECIFICATIONS ......................................................................14

EXPLODED DIAGRAM ..............................................................15

F25...................................................................................................... 15

F28...................................................................................................... 16

NOTES........................................................................................17

Tips for Healthy Frying........................................................................... 18

TIPS ON DEEP FRYING CHIPS.................................................19

APPENDIX A...............................................................................21

Residual Current Devices (RCD’s)...................................................... 21

EC DECLARATION OF CONFORMITY.....................................22

Warranty ..................... 23

Page 4

INTRODUCTION

Congratulations on your purchase of this quality ROBAND®product. With

proper care and management your new purchase will give you years of

trouble free service.

By reading these instructions carefully you can ensure that this machine is

used and maintained properly, helping your new investment to perform well

for you now, and to continue performing in the many years to come.

GENERAL PRECAUTIONS

This machine must only be operated by qualified person(s) who are fully

versed in the operating and safety instructions described in this manual.

Servicepersons should be instructed to familiarise themselves with any and

all safety instructions described in this manual prior to commencement of any

maintenance or service.

In the case of new personnel, training is to be provided in advance. These

machines should not be operated by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience or

knowledge, unless they have been given supervision or instruction

concerning the safe use of the appliance by a person responsible for their

safety.

These machines are heating units, and as with any commercial heating unit

the surfaces on these Fryers will get hot. Always be careful when near an

operating fryer, and ensure that any risk to unwary customers or staff is

minimised with additional signage if necessary. Due to the obvious heat

hazard Roband recommends that these units be kept out of reach of

children.

These Fryers are for use with oil. The machines are not designed for use

with water for such task as cooking pasta, and any such misuse will void

the warranty.

The machine should be disconnected from all power and allowed to cool

before cleaning.

Roband will accept no liability if;

♦ Non-authorised personnel have tampered with the machine.

♦ The instructions in this manual have not been followed correctly.

♦ Non-original spare parts are used.

♦ The machine is not cleaned correctly, with the right product.

♦ There is any damage to the unit.

Page 5

PACKAGING

All care is taken when packing and Roband ensures that every unit is

functional and undamaged at the time of packaging.

The Package of these Fryers should include:

1) One Fryer (appropriate model)

2) Two Control Boxes (appropriate types)

3) Two Fryer Baskets

4) This manual

5) Packaging materials

Any damage to the machine as a result of freight must be reported to the

Freight Company and to the agent responsible for the dispatch of said unit

within three (3) days of receipt. No claims will be accepted or entertained

after this period.

COMPLIANCE

C-Tick:

Roband®products have been designed and manufactured to comply with

any and all specifications set out by the Australian Communications

Authority (ACA) in regards to Electromagnetic Compatibility. As testament

to such compliance these units bear the C-Tick symbol.

For further information contact the Australian Communications Authority, PO

Box 13112, Law Courts, Melbourne VIC 8010.

CE:

Roband®products bearing the CE compliance mark have been designed and

manufactured to comply with European Standards and Directives. A copy of

the CE Declaration of Conformity is located at the back of these instructions.

ACSS (Advance Control Safety System):

The ACSS framework is a stringent and specific set of voluntary

requirements aimed at the electrical safety, reliability and longevity of

equipment used in the foodservice industry.

The ACSS framework has been developed as both a guide to the

engineering and development of products as well as a guarantee to

consumers that Roband equipment bearing this mark not only meets the

requirements of the Australian Standards, they exceed them.

Page 6

A unit bearing the ACSS mark is your guarantee that you are purchasing a

machine built to far exceed the Australian standards. The unit has been

designed to be safer, particularly from an electrical aspect, and last longer

than similar units on the market today.

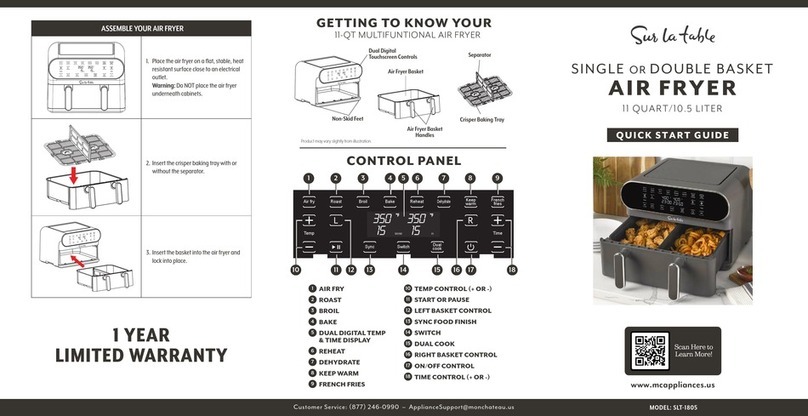

INSTALLATION

Remove all the packaging materials and tape, as well as any protective

plastic from the machine. Clean off any glue residue left over from the

protective plastic.

Place the fryer on a firm, level surface in the required position. The feet can

be adjusted for an uneven surface. Take a moment to familiarise yourself

with the general arrangement of the fryer before going any further. Notice

the activating switch located beneath the control box. The round activating

boss attached to the body of the fryer will activate this switch. Never

remove the activator boss.

National Standards exist outlining the positioning, spacing and ventilation

requirements when installing new appliances. These Standards should be

consulted and new equipment should be installed accordingly. In any

situation where specifications allow a distance of less than 100mm we

would still recommend that a well-ventilated air gap of not less than 100mm

be maintained. If the machine is near particularly heat-sensitive materials

common sense should be employed in determining sufficient distancing.

The elements and controls are designed as separate components to the

body and pans. These are referred to as the control boxes. The main

switches, thermostats and pilot lights are located on the face of each control

box. There are two control boxes on each fryer.

The control boxes can be tilted back and rested in the upright position or

removed altogether from the fryer body. Once removed, the pans may then

be removed by sliding your fingers beneath the lip and lifting them out.

Caution: Ensure pans are cooled before attempting to remove them.

Before connecting the fryer to the power supply ensure that all the controls

are in the “OFF” position.

For models, F25 and F25T plug each control box of the fryer into a standard,

single phase, 10Amp power point.

For models, F25E, F25ET, F28E and F28ET plug each control box of the

fryer into a standard, single phase, 13Amp power point.

For models, F28 and F28T plug each control box of the fryer into a standard,

single phase, 15Amp power point.

Page 7

Please Note: Each control box must be connected to an individual power

circuit.

We recommend the use of an RCD (Residual Current Device) rated at not

less than 30mA for circuit protection when using these units. Note that if one

RCD is used to protect multiple socket outlets, the RCD shall be

appropriately rated so as to allow up to 30mA from these machines alone.

Page 8

OPERATION

Place the pans in the fryer body. Place the control boxes in position and

the element guards over the element in the bottom of each pan.

Fill the pans with the required volume of oil. Refer to the safety note below

regarding “solid” oil. Refer to the specifications at the end of these

instructions, for the correct volume of oil for your particular model. Never

allow oil to fall below the minimum oil level as operation of the unit in this

manner could result in a fire.

Rotate the main switch to the “ON” position. The green pilot light will

illuminate, indicating that the power is on. Rotate the thermostat knob to

select the desired cooking temperature.

For cooking, a setting of between 170° and 180°C should suffice but

experience will dictate the best temperature for the particular food being

cooked.

When the temperature has been set the amber pilot light will illuminate,

indicating that heating is taking place. When the oil has reached the set

temperature the amber pilot light will go out. The thermostat will then

continue to cycle on and off, maintaining the set temperature. The amber

pilot light will also cycle on and off with the thermostat.

Solid Oil: If using “solid” type cooking oil, this must be melted very slowly

by turning the thermostat on to the lowest setting for about 10 to 15

seconds, then off for a similar period. Repeat this process until the level of

liquid oil reaches the minimum oil level mark. This is to prevent the

possibility of the oil igniting.

Extra Virgin Olive Oil: The flash point of Extra Virgin Olive Oil is

considerably lower than the more refined Olive oils and should not be used

for high temperature frying.

WARNING: Always turn both the thermostat and main switch “OFF”, and

allow element to cool before lifting the element out of the oil.

WARNING: Immersing a hot element in oil could cause a fire.

Cooking Tip: For frozen foods, direct from freezer to fryer, allow 5° higher

temperature or slightly longer cooking time. Always shake the cold water

and ice from frozen foods before frying. As a general rule, for larger items

of food, cook at a lower temperature for a longer time. For smaller items of

food, cook at a higher temperature for a shorter time.

WARNING: Ensure that oil is changed or filtered regularly. Old or dirty oil

has a lower flash point and is more prone to surge boiling.

Page 9

WARNING: always be careful when cooking frozen or over-wet food

products as these items are more prone to surge-boiling (where the “froth”

on top of the oil increases and can lead to an overflow of boiling oil and

water) and are more likely to result in the “spitting” of hot oil. It is always

safer to fryer smaller batches of product (never more than 0.5Kg) as this

will reduce the surging effect.

To obtain the optimum results from your fryer we recommend the following

guidelines.

♦ If a solid type cooking oil is used, melt it slowly at the minimum

temperature setting.

♦ Keep salt away from the cooking oil.

♦ Check your oil to food ratio, 6:1 oil to food is recommended.

♦ Filter the cooking oil regularly.

♦ Top up the cooking oil regularly.

♦ Never use copper or brass utensils in the cooking oil.

♦ Keep the fryer covered when not in use.

Page

10

aSAFETY a

GENERAL SAFETY

This machine contains no user-serviceable parts. Roband Australia, one of

our agents, or a similarly qualified person(s) should carry out any and all

repairs. Any repair person(s) should be instructed to read the Safety

warnings within this manual before commencing work on these units.

Steel cutting processes such as those used in the construction of this

machine result in sharp edges. Whilst any such edges are removed to the

best of our ability it is always wise to take care when contacting any edge.

Particular care should be taken to avoid contact with any steel edge, and

warnings should be given in regards to the danger of such contact to any

repair or maintenance person(s) prior to commencement of any servicing.

Do not remove any cover panels that may be on the machine.

This unit can get very hot, ensure everyone is aware that the machine is

operating and take care to avoid contact with hot surfaces (refer to

installation for guide to ventilation).

Always ensure the power cable is not in contact with hot parts of the

machine when in use, and ensure that if the cord is damaged in any

way that is replaced immediately.

SAFETY FEATURES

All fryers in this range are equipped with a thermal overload.

The thermal overload’s function is to cut power to the fryer when the oil

temperature reaches 238°C, thus preventing the oil reaching flash point

temperature.

If the thermal overload trips it can be reset by pushing the button on the

rear of the control box. If the thermal cutout continues to trip there may be

a fault with the thermostat and you should contact your nearest authorised

service agent for further help.

Models F25-UK are also fitted with a Tilt Switch designed to cut all power if

the element is tilted out of the oil or if the element box is removed.

GENERAL FIRE SAFETY

Before using any fryer adequate safety measures should be in place. Such

measures should include, but not be limited to, having an appropriate fire

extinguisher or fire blanket located nearby in case cooking oil ignites.

Electricity is dangerous, and should only be handled by

qualified professionals. It’s your life – Don’t risk it.

Page

11

CLEANING, CARE & MAINTENANCE

Attention to regular care and maintenance will ensure long and trouble free

operation of your fryer.

♦ The Fryer should be cleaned out daily, or more often if necessary.

♦ Ensure the power is off and the fryer is cool before attempting to drain the

cooking oil or clean any part of the machine.

♦ Wipe the fryer down with warm soapy water using a damp sponge or

cloth. Do not immerse the control boxes in water.

♦ Filter the cooking oil daily if the fryer is constantly in use.

♦ Empty and wash the drip tray at the bottom the fryer regularly. The tray

is removed by simply sliding it out.

Although every care is taken during manufacture to remove all sharp edges,

care should be taken when cleaning to avoid injury.

Caution: Some cleaning agents can damage stainless steel, usually

through prolonged use. For this reason we recommend cleaning with

soapy water. Any damage to the unit through the use of harsh or

improper cleaning agents is entirely the fault of the user.

Warning: No parts of this these units, with the exceptions of the oil pan

and drip tray, should ever be immersed in water for cleaning or any

other purposes.

Note: We recommend that all electrical appliances be inspected

annually with reference to applicable Australian or local Standards to

ensure that compliance with changing Standards is maintained. Such

inspections should be carried out by a suitable person conversant with

the latest Standard updates.

Page

12

TROUBLESHOOTING

If the fryer does not function check the following points before calling

for service.

The control boxes are plugged in correctly & the power switched on.

The On/Off switch is On.

The power points are not faulty.

The temperature has been set correctly and the overloads have not

tripped. To reset a tripped temperature overload switch, press the

red button behind the control box as indicated in the picture below.

Frequent tripping of the overload may indicate a problem.

The thermostat knobs are not loose or broken, rendering the

thermostats inoperable.

RESET BUTTON

Page

13

CIRCUIT DIAGRAM*

Models F25, F25E, F28, F28E version 3-UK

=Diagram is of a single control box. Each Double Pan Fryer contains two

such control boxes. F25-UK includes an additional tilt switch in the active

leg.

NOTE: Tilt switch for UK Models ONLY.

TC – Thermal cut-out

TS – Thermostat

*This circuit diagram has been provided for reference and to assist

qualified service and repair agents only. Under no circumstances

should a person not suitably qualified attempt repairs to any electrical

equipment.

Page

14

SPECIFICATIONS

F25-UK

F25

F25E

F28

F28E

Model

------------

------------

220-240

Volts AC

------------

------------

---

Power

Source

2 x 2735 -

3255 W

2 x 2400 W

2 x 3150 W

2 x 3600 W

2 x 3150 W

Power

Consumption

2 x 5 L

2 x 5 L

2 x 5 L

2 x 8 L

2 x 8 L

Oil

Volume

538mm

538mm

538mm

538mm

538mm

Width

340mm

340mm

340mm

390mm

390mm

Height

425mm

425mm

425mm

425mm

425mm

Depth

Nominal Dimensions

Constant Research & Development may necessitate machine

changes at any time.

Page

15

EXPLODED DIAGRAM

F25

Page

16

F28

Page

17

NOTES

Record any preferred times or settings etc. here to act as a quick reference for other

users.

Page

18

TIPS FOR HEALTHY FRYING

Are you concerned about your customers’ health? Would you like to improve

the flavour and nutritional value of your fried product? And would you like to

save money doing so? Then read on and take the first step towards a higher

quality healthier product that actually can help save you money…

Saving Costs, Improving Oil Life and Increasing Efficiency

Food quality and operating efficiency is improved by cooking in regularly

filtered oil. Long oil life can be achieved by frequently filtering the fat and oil

inside the deep fryer. This allows the oil to work at greater efficiency for a

longer time.

This improvement can be associated with increased efficiency; including

power cost savings and a longer fry life for the fat or oil.

Several factors that shorten the fry life of the oil include the presence of

water, emulsifiers, seasoning, light and detergent.

Various Types of Fats and Oils

Different types of oil or fat used to fry foods affect the overall nutritional

quality of the finished product. Many of the various types of fats and oils

available on the market are not suitable for cooking over long periods of

time at high temperatures, as happens in deep-frying.

Tallow-based (Beef) Fats

The most commonly used fat due to its cheaper cost and relatively longer

fry life. This oil is not recommended due to it’s association with increased

heart disease risk.

Liquid Vegetable Oils

Whilst most vegetable oils are recommended for cooking, many of them

are not suitable for deep-frying. Higher temperatures break down the oil

faster and by-products often have an off-flavour and that may also increase

heart disease risk.

HARDENED/ CREAMED VEGETABLE OILS

These products may have a longer fry life than their liquid oil equivalents,

but the hardening process increase heart disease due to the components

added.

The Heart Foundation recommends frying oils that have a nutrient profile

taking all these factors into account. These include:

1. Oils from specially bred seeds eg Sunola, Liquid Gold

2. Industry blends of fats and oils

Page

19

TIPS ON DEEP FRYING CHIPS

1. Use thick, straight cut chips (greater than 13mm) or

wedges

• Thin chips and crinkle chips absorb more oil and therefore use

up more oil from the fryer

• If the chips are frozen, don’t thaw. Water from thawed chips

damages the oil

2. Cook at 180°C

• Food won’t cook more quickly at temps above 180°C

• Higher temps damage the oil

• Damaged fat: - cooks more slowly

- uses more electricity to cook the food

- takes longer to get back up to

temperature

• Lower temperatures produce greasy food

• Turn fryer to 140°C during quiet times to save power and save

the oil

3. Cook chips in a separate fryer

• Fresh batter mix used for battered food, crumbs from crumb

coatings, seasonings, sausages and seafood all damage the

oil.

• If you have enough fryers, keep one fryer for chips only, this oil

will last longer

4. Cook chips for 4 - 5 minutes

5. Avoid big drops in oil/fat temperature

• Big drops in temperature will damage the oil more quickly.

• Put small loads in the baskets

• If you have enough fryers, put baskets in alternate fryers.

• Keep fryers topped up with fresh oil. Don’t top up whilst cooking

food.

Page

20

6. Drain chips well

• Vigorously shake the basket of cooked food twice and hang it

for at least 20 seconds over the hot fryer. This returns some oil/

to the fryer

7. Look for signs of oil degradation

• If the oil is damaged (eg dark colour, smoking) discard it all.

8. Filter oil daily

• Use a funnel or a filtering machine

• The cost of a filtering machine will be offset by your savings on

the oil

• Filtering extends the useful life of the oil

• Skim the surface of the oil frequently while cooking

9. Clean fryer frequently

• Detergent damages the oil. If you use detergent, rinse well after

with a solution of white vinegar and water (1 cup of vinegar in a

20 litre bucket of water.) Finally rinse with water.

• Occasionally it may be necessary to fill the fryer with water and

boil 15-30 minutes to help loosen any gum formed on the fryer.

10. Cover the fryer

• As light, dust and air damage oil, cover the fryer overnight and

other times during the day when oil is cool.

This manual suits for next models

4

Table of contents

Other ROBAND Fryer manuals