6Eastwood Technical Assistance: 800.343.9353 >> techelp@eastwood.com To order parts and supplies: 800.343.9353 >> eastwood.com 3

READ INSTRUCTIONS

• Thoroughly read and understand these product instructions before using

this tool. Failure to follow all warnings can result in tool damage or serious

physical injury.

• Save for future reference.

EYE INJURY HAZARD!

• Rapidly rotating surfaces can eject metal particles, dirt and debris at

high velocity. Always wear ANSI approved eye protection when operating

this tool.

HEARING DAMAGE HAZARD!

• This Rockwood Pneumatic Tool emits high sound levels while operating.

Use ANSI approved ear protection when operating.

BURSTING HAZARD!

• Do not exceed 90 psi (6.3 bar) of tool inlet pressure. Permanent tool damage

and/or explosion could occur and cause personal injury.

INJURY HAZARD

• This tool has high-speed, rotating components which can quickly cause

severe injury. Keep fingers and hands away from moving parts when

operating. Wear thick, well-fitting work gloves and keep loose clothing,

sleeves, cords, jewelry and hair away from moving parts.

INJURY HAZARD

• This tool could eject sparks at high speed which can ignite flammable

materials or injure others nearby. Do not operate near flammable materials

and keep all persons and pets away from the work area.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION used with the safety alert symbol, indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

SAFETY INFORMATION

The following explanations are displayed in this manual, on the labeling, and on all other information

provided with this product:

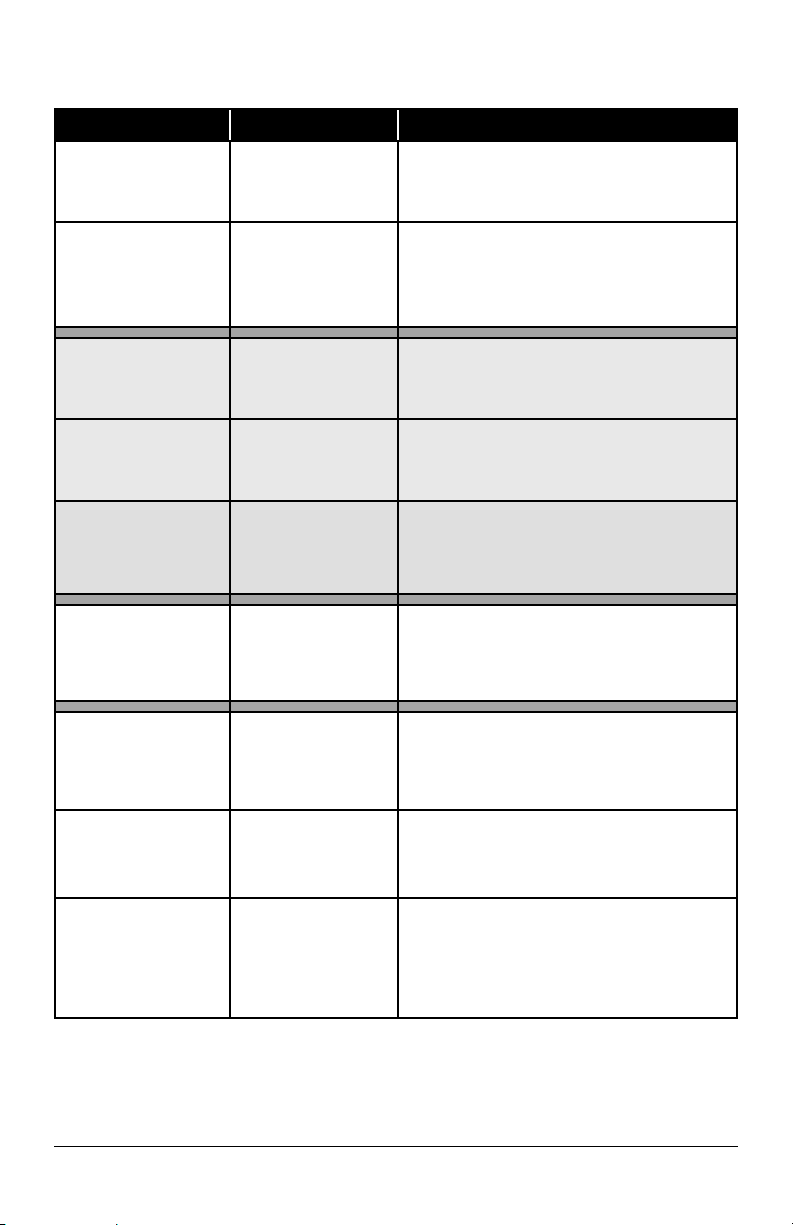

PROBLEM CAUSE SOLUTION

Tool doesn’t

respond to trigger

depression

Insufficient volume

of air (CFM) to

operate tool

Verify sufficient air supply to tool.

(4 CFM @ 90 PSI minimum requirement)

Moisture or other

contamination in

air supply

Check for moisture in air line

and tool air inlet

Tool performance

is slow or sluggish

Insufficient volume

of air (CFM) to

operate tool

Verify sufficient air supply to tool.

(4 CFM @ 90 PSI minimum requirement)

Moisture or other

contamination in

air supply

Check for moisture in air line

and tool air inlet

Air Motor is lacking

lubrication

Stop use immediately and add air tool oil

directly to air inlet

Tool is excessively

noisy/emits high

pitched sound

Air Motor is lacking

lubrication

Stop use immediately and add air tool oil

directly to air inlet

Tool vibrates

excessively

during use

Loose Chuck Jaws Tighten Chuck Jaws

Out of balance

condition from

damaged Chuck

Stop use immediately, check for damaged

Chuck

Out of balance

condition from

damaged drill bit

or accessory

Stop use immediately, replace damaged

drill bit or accessory

TROUBLESHOOTING