Roger Technology B70/1DCHP User manual

Quick Start B70/1DCHP

Rev02 03/04/2020

ROGER TECHNOLOGY

Via S. Botticelli 8 • 31021 Bonisiolo di Mogliano Veneto (TV) • ITALIA

P.IVA 01612340263 • Tel. +39 041.5937023 • Fax. +39 041.5937024

info@rogertechnology.com • www.rogertechnology.com

APower supply H07RN-F 3x1,5 mm2 double insulated cable

1Photocell - Receiver 5x0,5 mm2double insulated cable (max. 20 m)

2Photocell - Transmitter 3x0,5 mm2double insulated cable (max. 20 m)

3Flashing lamp unit 2x1 mm2double insulated cable (max. 10 m)

4Antenna RG58 50 Ohm cable for external use (max. 10 m)

5Selector / Keypad 3x0,5 mm2cable (max. 20 m)

1. Typical installation

B70/1DCHP is the range of 36V DC digital controllers installed with the BG30 product series for sliding gate applications.

EN

1

A

1

5

2

2

3

4

2. Electrical connections

3. Display: functions and settings

PROG TEST

+

-

Back

Programming Check error alarms

PARAMETER PARAMETER

VALUE

Increase value

Decrease value

Next

PROG TEST

+

-

Accessories illustrated are indicative only

+SC

8910 11 12 13 14 15

16 17 18

19 20 21 22 23

24 25 26 27

COM

FT2

FT1

COS2

COS1

COM

ST

+LAM

COM

COM

ANT

COR

+24V

PED

PP

CH

AP

ORO

COM

LNA

LNB

ENC

MOTOR

POWER SUPPLY 230Vac

YXZ

F2

FC SB

P

R

OG

TE

S

T

+

-

M

F4ES-F4S

Series

R85/60

BG30

CS/STD

1 2 3 2345

+- +-

TX RX

L

N

12

F1

1

FIFTHY/24BATTERIES

+

COM

NO

-

SEC2 SEC1

BATTERY

BATTERY CHARGER

TRANSFORMER

M

-+

YXZ

2 x 12V 4,5Ah

4. Before starting ...

a) Select the automation system model installed with the parameter .

PROG TEST

+

-

PROG

TEST

+

-

PROG TEST

+

-

GATE OPENS TO LEFT

GATE OPENS TO RIGHT

BG30/1600 BG30/1400/R

BG30/2200 BG30/1800/HS

BG30/1000/HS BG30/1500/HS

d) Move the gate into the completely CLOSE position.

Check that, by pressing the TEST button, the display

always shows FC.

e) Press the TEST button. Possible alarms and safety device messages:

SEE ACQUISITION PROCEDURE

b) Select the position of the motor relative to the gate with the parameter

. The default setting for this parameter is with the motor installed on

the right hand side of the gate (seen from interior side).

c) Adjust the (mechanical or magnetic) limitswitches

so that, once triggered, the gate stops slightly

before it reaches the mechanical stop.

CLOSING LIMIT SWITCH OPENING LIMIT SWITCH

00 No safety device in alarm state and no limit switch activated.

Sb (Sb) Release handle or lock open.

STOP contact (N.C.) open.

Jumper the STOP contact.

5 Sensing edge contact COS1 (N.C.) is open. Check connection. If sensing

edge is not installed, disable with 3 00.

4 Sensing edge contact COS2 (N.C.) is open. Check connection. If sensing

edge is not installed, disable with 4 00.

3 Photocell contact FT1 (N.C.) is open. Check connection. If photocell is not

installed, disable with 50 00.

2 Photocell contact FT2 (N.C.) is open. Check connection. If photocell is not

installed, disable with 53 00.

fe Both limit switches in error state. Check connections and settings of limit

switches.

fa If gate is open, gate open limit switch is detected.

fC If gate is closed, gate closed limit switch is detected.

Speed Speed

Closing speed BH30/HS-BM30/HS

Approach

distance

Approach

speed

Approach distance

Approach speed

Deceleration

Deceleration

during closure BH30/HS-BM30/HS

Deceleration

Acceleration Acceleration

Acceleration during closure

BH30/HS-BM30/HS

CLOSE OPEN

Boost during aperture

Boost during closure

0° 0°

Maximum motor torque setting according to defined time

Setting motor torque

Minimum torque

Maximum torque

Obstacle detection

sensitivity setting

Maximum sensitivity

Minimum sensitivity

Setting reverse time after

activation of sensing edge

or obstacle detection

(crush prevention).

5. Acquisition procedure

1. Press and hold PROG for 4 seconds.

2. APP- appears on the display.

3. Open the release cover.

4. PHAS appears on the display.

5. Wait until the message PHAS flashes.

6. Close the release cover.

7. If the photocells are connected and enabled (FT1/FT2), the message FOTO flashes. NOTE: do not break the photocell barrier beam.

8. AUTO appears on the display.

9. The gate starts to open.

10. Once the gate is open, the message AUTO flashes on the display after a few seconds and the gate starts to close.

11. When the gate is closed, the safety device symbols are displayed.

PROG

AP P- PH A5 AU to

x4 s

x5 s

OPENING OPEN CLOSING

(if FT1/FT2 are

connected or enabled)

CLOSE

Yes

AU

AU

to

to

PH

PH

A5

A5

FO

FO

TO

TO

CLOSE

6. Setting basic parameters

7. Programming a NEW transmitter

8. Copying a transmitter

1. Press channel P1 (P2) of the receiver.

2. When LED L1 (L2) ashes 3 times (or 4 times

with rolling code function), press any button

on the transmitter.

3. If LED L1 (L2) remains steadily lit the

transmitter has been stored correctly.

1. Press buttons A and B on the NEW

transmitter simultaneously.

2. The LED ashes for 5 s.

3. Hold button (A) only on the NEW transmitter

you want to store.

4. The LED ashes 3 s.

5. Hold the previously stored transmitter as

close as possible to the NEW transmitter.

6. Press button (A) on the OLD transmitter.

7. The LED lights for 1 s to conrm that the copy

procedure was successful.

P1

L1 L2

P2 P1

L1 L2

P2

ON

P1

L1 L2

P2

1 click

x5 s x3 s x1 s

AAA

A

B

OLD

This document is a basic quick guide for the initial installation of a BRUSHLESS sliding gate motor.

For complete information concerning the control unit, the motor and the accessories mentioned in this quick guide, see the technical manuals available in the B2B area of the

website www.rogertechnology.it

9. Photocells grounding connection

Grounding connection negative terminal (COM) photocells series F4ES/F4S or other than Roger Technology

In case of malfunction, or failure to intervene in case of dimming, or continuous detection, or abnormal behaviour of the automation (gate, overhead door,

barrier, etc.), it is advisable to connect the negative terminal (COM) of the photocells to the grounding of the system.

+SC

8910 11 12 13 14 15

16 17 18

19 20 21 22 23 24 25 26 27 28 29

COM

FT2

FT1

COS2

COS1

COM

ST

+LAM

COM

ANT

+24V

PED

PP

CH

AP

ORO

COM

LNA

LNB

RX

TX

12 3 12

RX

TX

FT1

FT2

MASTER

SLAVE 1

345

123 12345

rosso

red

nero

black

F3

LN

COM(-)

COM(-)

COM(-)

COM(-)

COM(-)

COM(-)

Other manuals for B70/1DCHP

3

Table of contents

Popular Range manuals by other brands

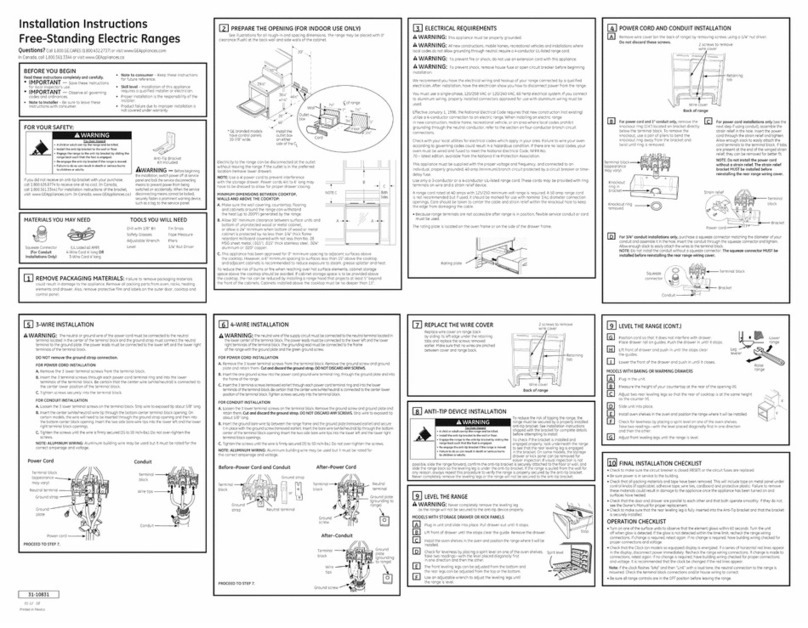

Siemens

Siemens HC854 83 Series instruction manual

GE

GE JCB800 Owner's manual and installation instructions

GE

GE JGBP28BELWH Dimensions and installation information

Bosch

Bosch HGS5022UC-01 use and care manual

Fisher & Paykel

Fisher & Paykel OR30SDG6X1 installation guide

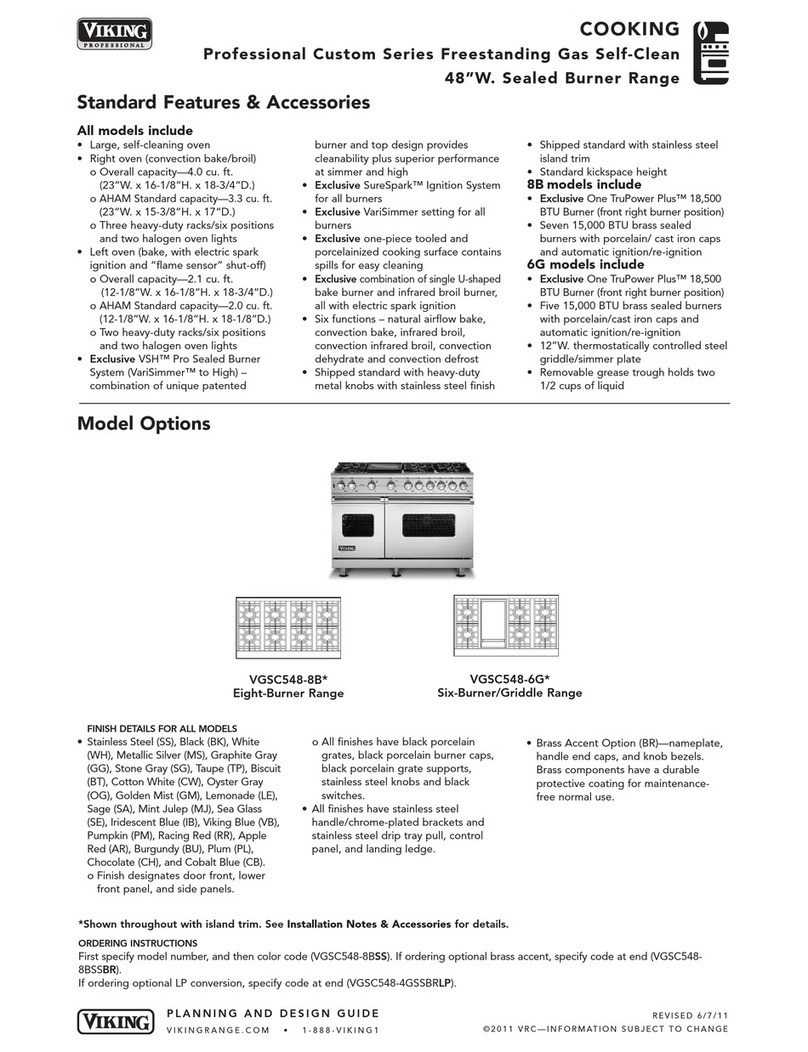

Viking

Viking VGSC548 Planning and design guide