Recoil Starter. Firmly grasp the handle and pull slightly until engagement can

be felt. Then pull forcefully, being careful not to pull the rope all the way out.

Return the starter rope gently.

Rider Seat Suspension. The seat suspension spring can be adjusted to suit

the rider’s weight and riding conditions. Adjust the spring per load as follows:

To increase the spring preload, turn the adjuster clockwise. To decrease the

spring preload, turn the adjuster counterclockwise.

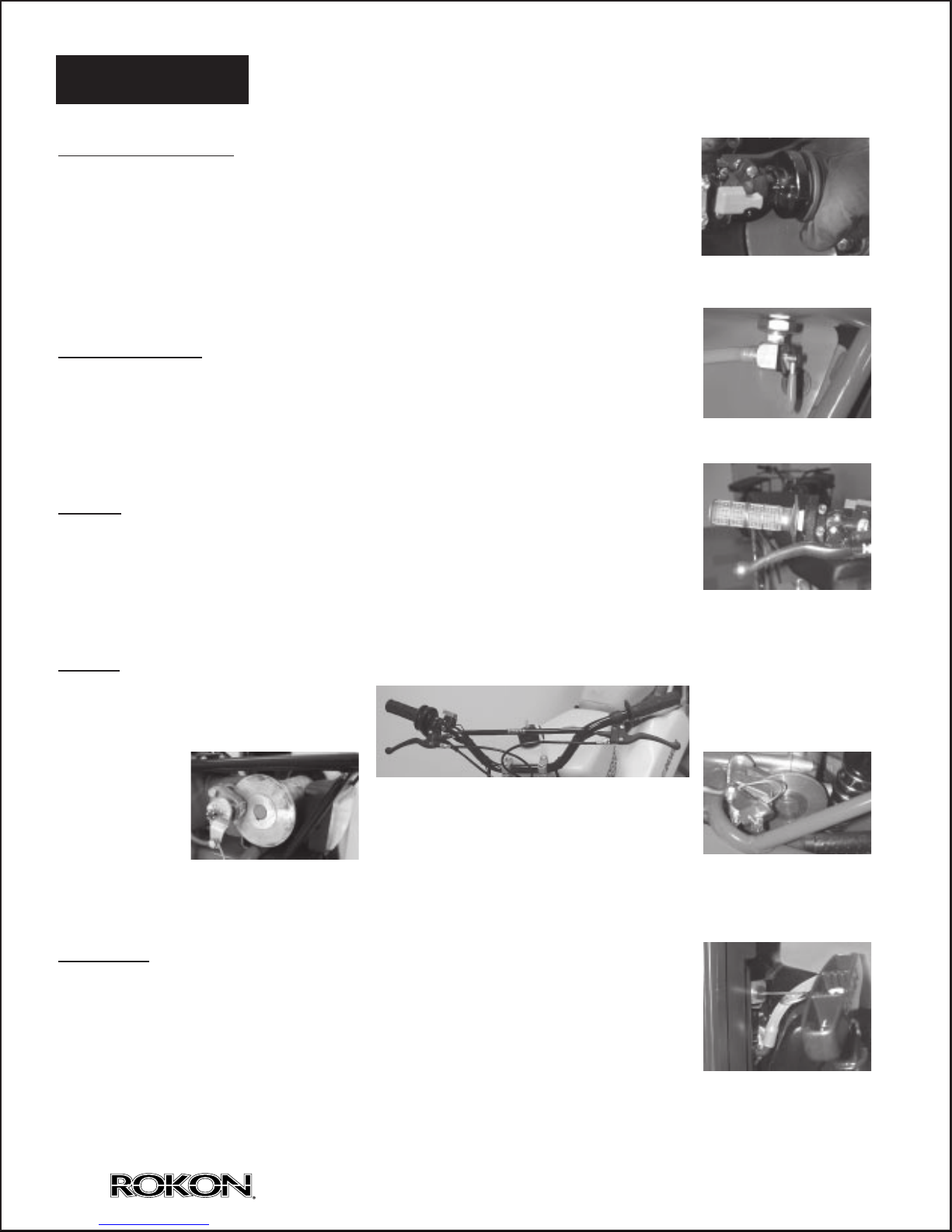

Transmission: The three range transmission is a ratio selector and when

coupled with the automatic torque converter, gives the vehicle extremely

broad capabilities, from steep climbing to normal transporting. The torque

converter provides a large overlap of speed and torque between gears.

This makes frequent gear changes unnecessary. Therefore, the trans-

mission has not been designed to shift in motion. STOP THE VEHICLE

BEFORE SHIFTING. Shift only at low idle or when the engine is off. Feel

the gears into engagement, rocking the bike, if necessary, to synchronize

the gears. The shift pattern is from inside out: 3-N-2-N-Low.

Automatic Torque Converter: The torque converter is designed especially

for ROKON and provides smooth automatic clutching and ratio

changing in response to throttle control and terrain requirements. The

front drive pulley tends to shift into high as engine speed is increased.

The rear driven pulley follows this speed change. If torque requirements

increase, the cam in the torque-sensing rear pulley overrides the front

pulley and forces a down shift without a loss of engine revs and power.

WARNING:

Potential Hazard- Starting the engine in gear.

could cause the Rokon to move forward unexpectedly.

PUT THE TRANSMISSION IN NEUTRAL BEFORE

STARTING THE ENGINE. Stand on the left hand side,

put the front Brake on with 2 fingers of your left hand, throttle

closed, reach over the ROKON and pull the starter handle.

Section 3 Continued Control Functions

7

ROKON INTERNATIONAL, 50 Railroad Ave., Rochester, New Hampshire 03839, U.S.A. Copyright 2004