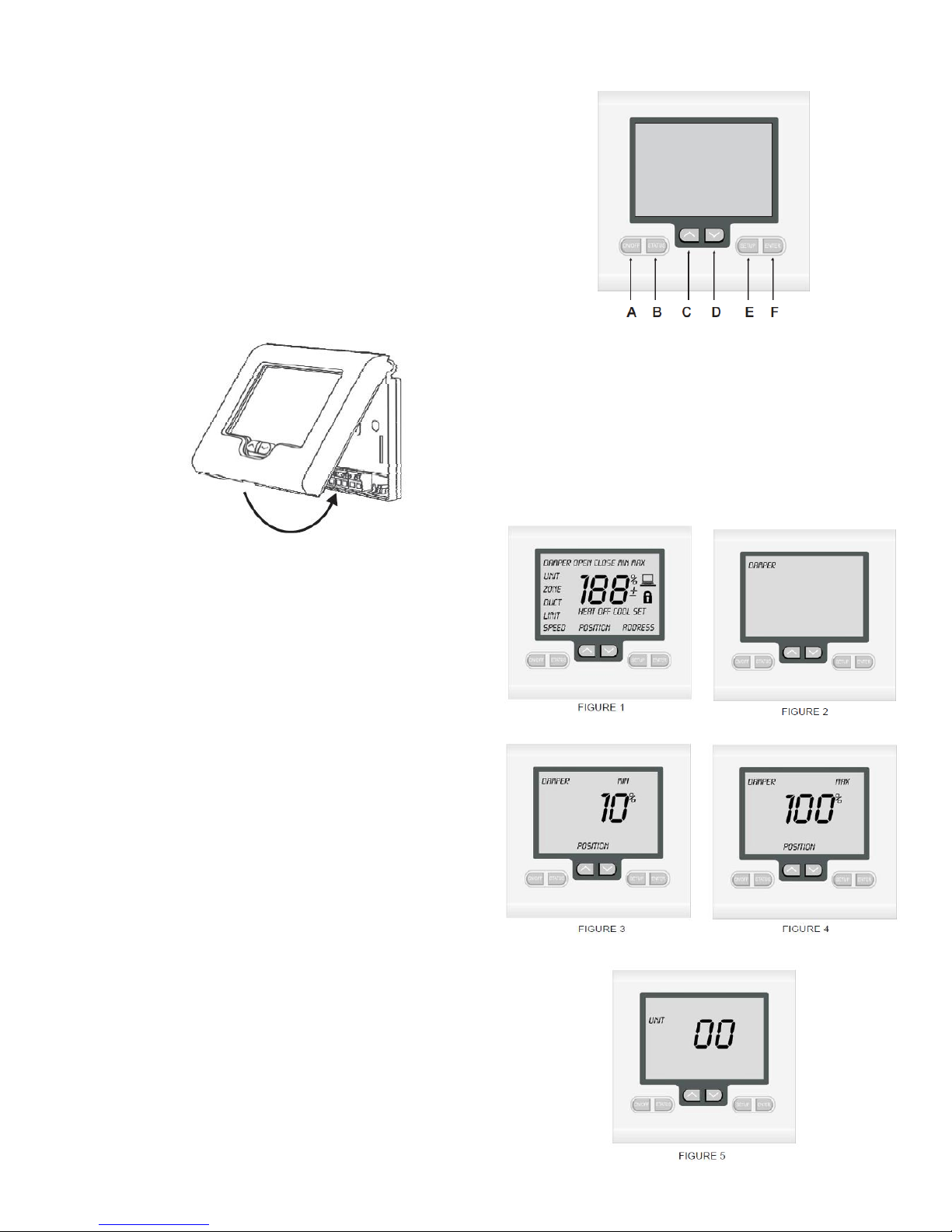

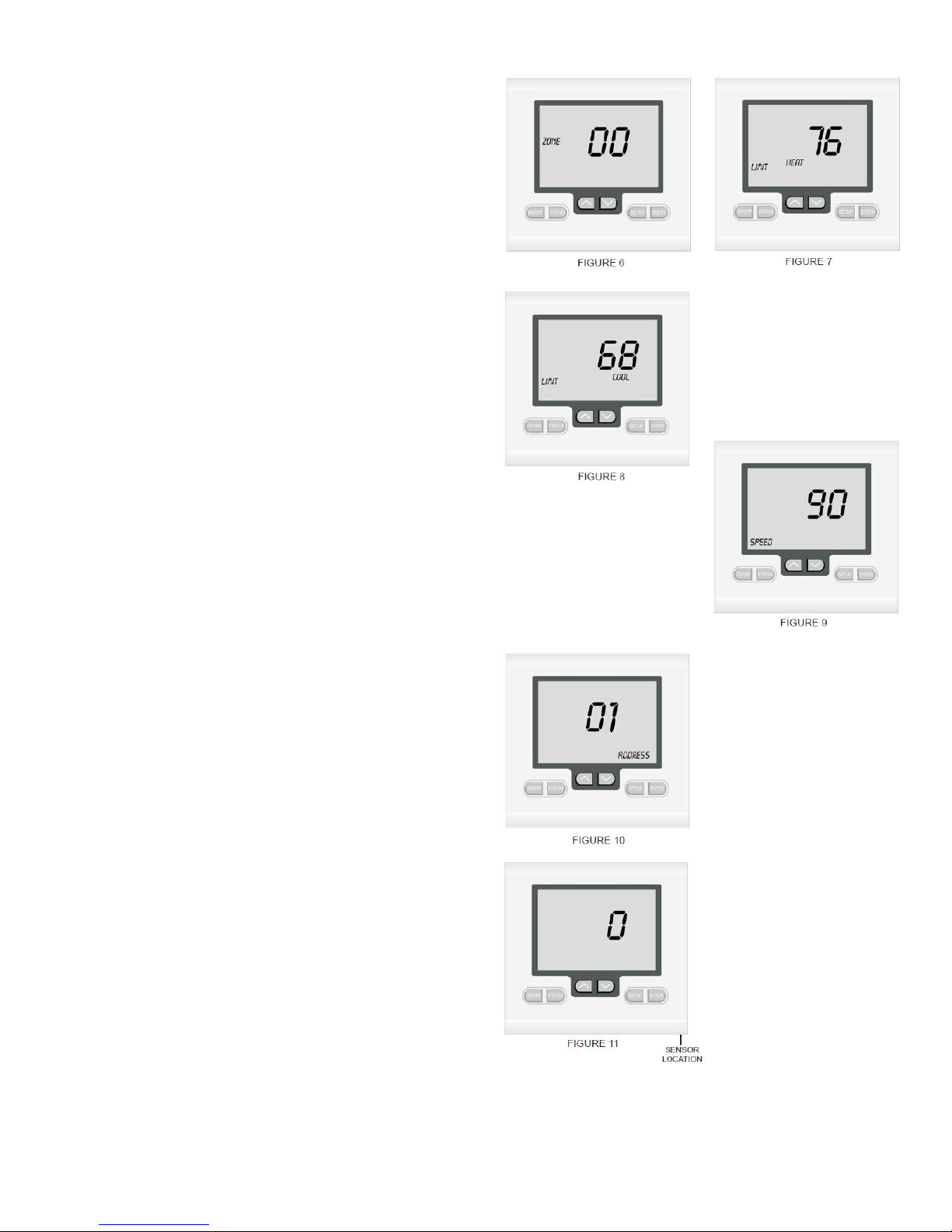

SETTING A ZONE NUMBER

Press the SETUP key again and the LCD will display

the word ZONE. The factory default is 00. This number

can be used to identify each Z2000RT thermostat wired

to a Z2000 zone control panel or when used in multiple

stand-alone applications. Use the UP and DOWN keys

to assign a ZONE number from 00 to 99. (Figure 6)

SETTING THE HEATING LIMIT

Press the SETUP key again and the LCD will display

the heating limit. The factory default is 76° F. Press the

UP and DOWN keys to change the heating limit setting.

It is strongly recommended that the limit not be set

Above Thefactory default setting. (Figure 7)

SETTING THE COOLING LIMIT

Press the SETUP key again and the LCD will display

the cooling limit. The factory default is 68° F. Press

the UP keys to change the cooling limit setting. It is

strongly recommended that the limit not be set below

the factory default setting. Refer to Figure 8.

SETTING THE ACTUATOR SPEED

Press the SETUP key again and the LCD will display

the actuator speed. The factory default is 90 seconds

which is the time it takes the actuator to drive the

damper blade fully open or fully closed. This is a critical

step in the Z2000RT setup since the thermostat can

be used with a variety of 24 Volt actuators. If you are

unsure of the actuator speed, place the actuator in the

fully closed position and then apply 24 Volts to common

and normally open. The time it takes to drive the damper

blade fully open equals the actuator speed setting.

(Figure 9)

SETTING THE MODBUS ADDRESS

Press the SETUP key again and the LCD will display

the Modbus communications address. The factory

default is 01. The Z2000RT has integrated Modbus

communications capability for remote monitoring

and control. For more information on Modus

Communications, contact Ruskin (Figure 10).

TEMPERATURE CALIBRATION OFFSET

Press the SETUP key again and the LCD will display

the temperature calibration offset as shown on

Figure 11. The factory default setting is 0. Typically,

it is not necessary to adjust the temperature calibration

offset as the Z2000RT has been factory calibrated.

If calibration is necessary, a high quality electronic

digital thermometer must be used. Place the

thermometer sensor probe next to the thermostat

sensor and allow five minutes before comparing

the temperature readings. Use the UP and

DOWN keys to adjust the temperature calibration.

The range is +/- 9° F.

6