4

OPERATING PARAMETERS

Ambient temperature: Max 104°F

Liquid temperature range: 32°F to 194°F

Operating pressure: Max 142 psi

Inlet pressure: Max 85 psi

GTPH 2T GTPH 4T

Flow (gpm): 4 to 16 8 to 36

Head (feet): 20 to 220 25 to 240

GTPH 8T GTPH 12T

Flow (gpm): 17 to 44 35 to 70

Head (feet): 40 to 160 10 to 210

GTPH 25T GTPH 50T

Flow (gpm): 65 to 200 130 to 380

Head (feet): 20 to 220 40 to 190

MOTOR DATA

Nominal speed: 3500 rpm at 60 Hz

Standard voltage: 3 phase; 230V/460V

Protection class: IP54

Insulation class: F

INSTALLATION–SECTION B

! WARNING !

When running, the motor surface

temperature is extremely high. Mount pump

in a safe place to avoid accidental touch.

INSTALLATION SITE

1. Select a dry and good ventilated site and

provide accessible space around the pump

for future maintenance and service.

2. Mount and bolt the pump base to the

foundation.

3. Make sure the ambient temperature is

below 104ºF and the pumped liquid

temperature does not exceed 194ºF.

4. Do not operate the pump in an explosive

environment.

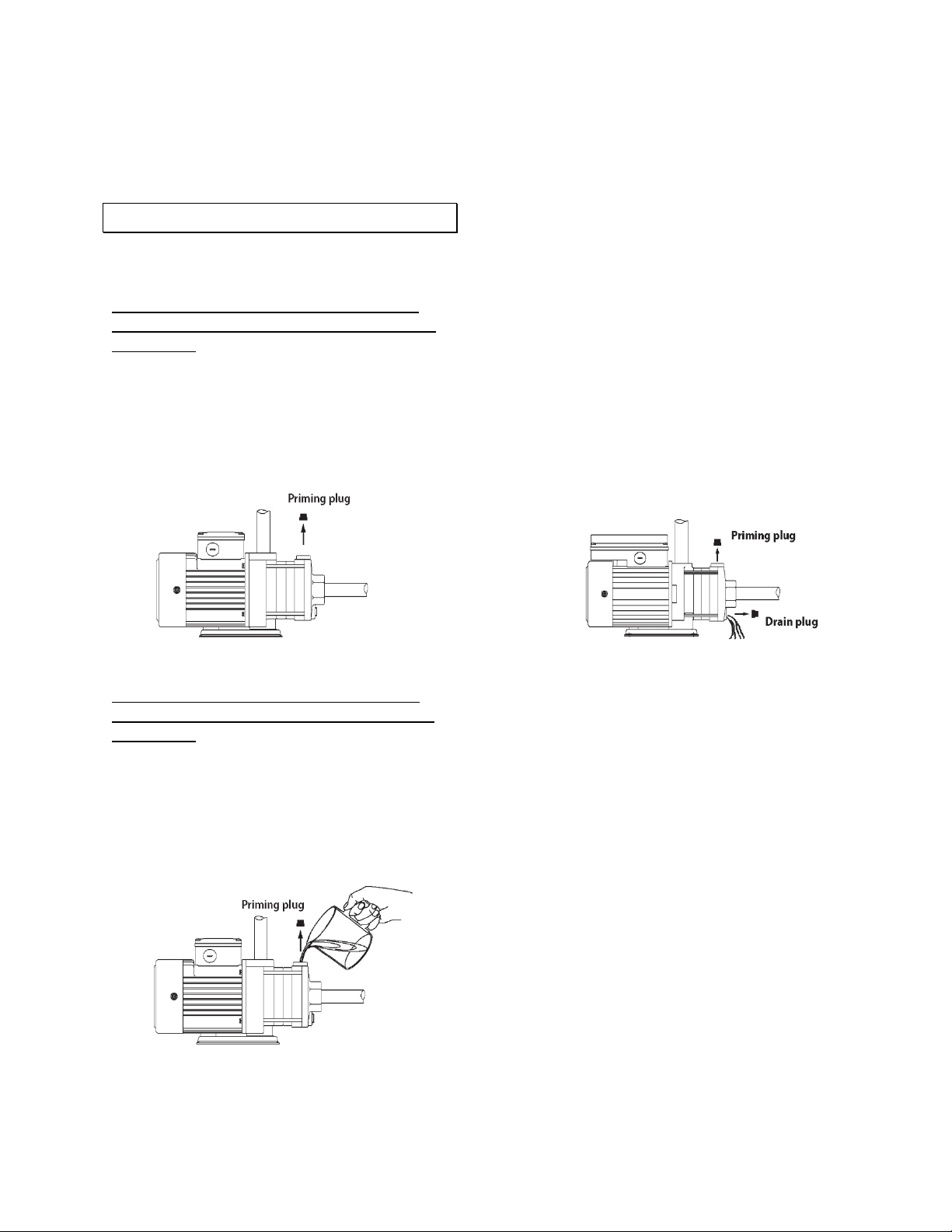

5. Horizontal installation is recommended.

When it is installed in other positions, rotate

intake flange so that drain hole is at the

lowest position.

6. Indoor: do not install the pump on ceiling,

carpet, or near electrical appliances.

Provide drain hole.

7. Outdoor: provide a suitable cover to protect

pump from weather and frost, prevent

debris from falling into the motor fan cover.

PIPING

1. The pump should be installed so that the

suction pipe is as short as possible.

2. When you draw liquid from the same level

of the pump suction inlet, allow a slope from

the liquid source to the suction inlet to avoid

air lock. If it is to pump liquid from a level

lower than the pump suction inlet, a foot

valve check valve must be fitted to the end

of the suction pipe.

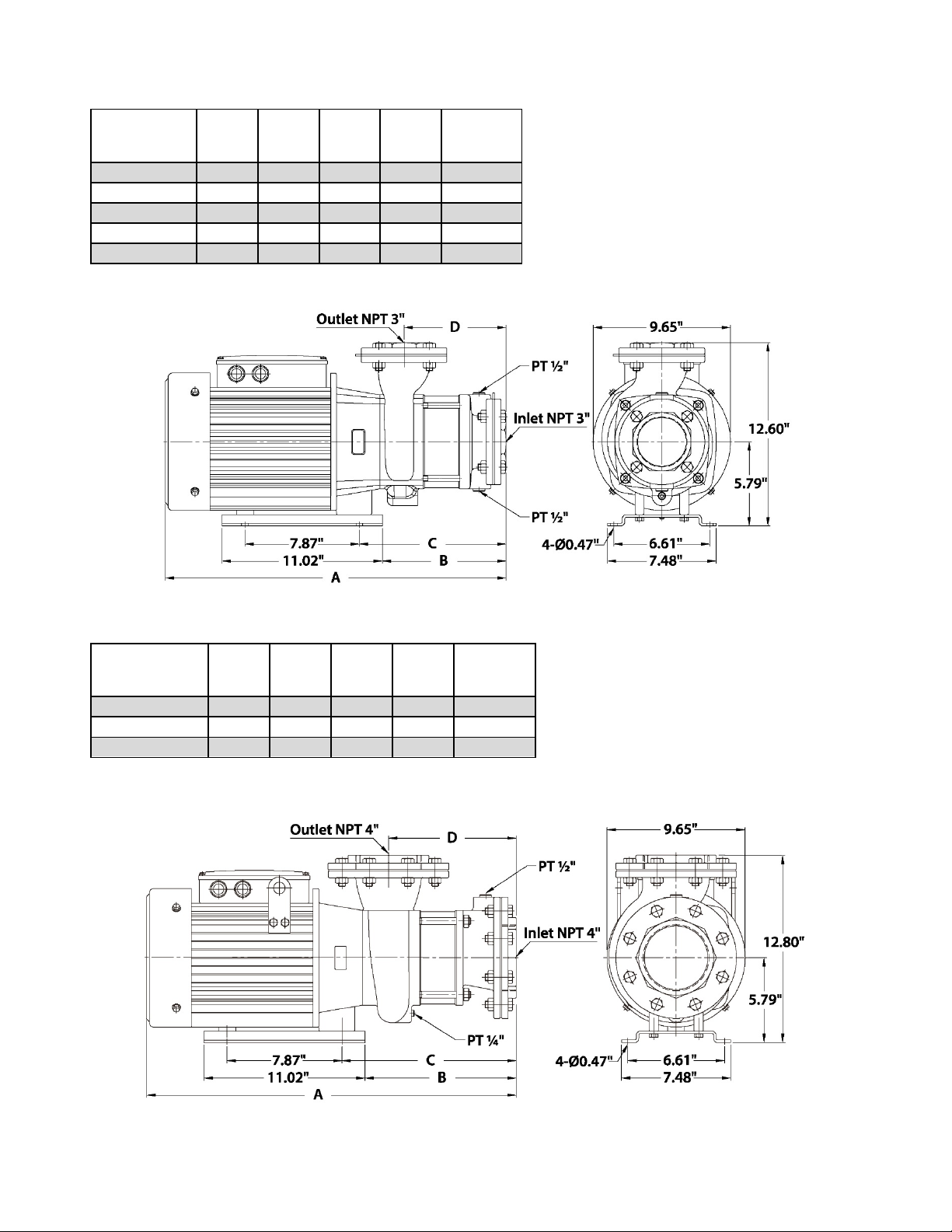

3. Select the pipe size specified in the pump

outline drawings in DIMENSIONS

SECTION-F. Smaller piping will cause

considerable pressure loss and affect pump

efficiency.

4. All piping joints must be completely tight.

Leakage in suction piping may result in the

loss of the suction capability. Leakage in

discharge piping may cause the "cycling" of

the pump.

5. Prevent any foreign objects (chewing gum,

dirt, and sand etc.) from falling into the

pump or motor.

6. The pump lifting capacity is related to the

temperature of the pumped liquid. Under

normal liquid temperature (68ºF – 86ºF), it

will lift up to 16Ft. At high temperature

operation (over 140ºF), the pump must be

installed at the level lower than the liquid

source or the pump inlet pressure must be

higher than 15 psi.

7. It is extremely dangerous to run the pump

against a closed discharge valve. Doing so

will cause extremely high liquid flow

temperature and damage the pump.

Connect a bypass/a drain to the discharge

pipe to allow a minimum liquid flow through

the pump.

8. Metal piping is recommended when the

operations require high lifting head or high

liquid temperature.