-:,:,,-~~ccc'

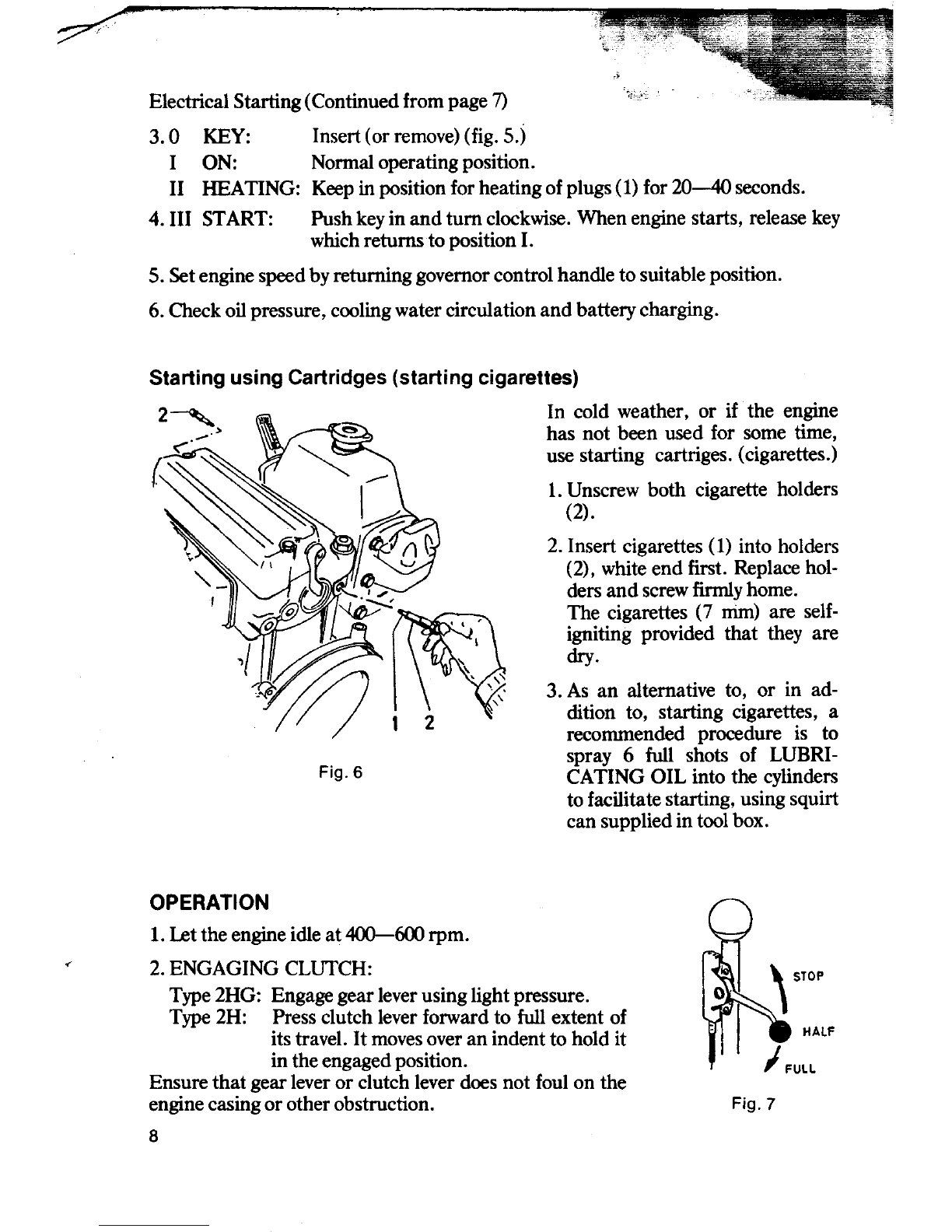

1.Unscrewnut(3)oneturn.

2.Insertpin in headof adjustingscrewand

adjustpositionof screw,in or out, when

engineisrunningatmaximumspeed.

3.Set position of adjusting screw so that

maximumpropellerpitch correspondsto

theoptimumvalueof fu11speedrpm from

the point of view of vibration and boat

speed.This enginespeedwill dependon Fig.9

theboat'ssizeandhuIl form. It win nor-

mally he in the regionof 200) rpm and

mustnotexceed2250.

Notethat the propulsivepowerof theengine(propellertorque)is nearlyconstant

for enginespeedsin therange1800-2(XX)rpm but falls at higherenginespeeds.

Thismeansthat,withacontrollablepitchpropeller,maximumpropulsivepowerwill

heobtainedin trosenginespeedrange.Thereis thereforelittle point, in thecaseof

mostboats,ofrunningtheengineat themaximumof 2250rpm. Onlyif theboatis

particularlyeasytopropelwill theuseof maximumrpm resultin higherboatspeed.

If theboatisusedforfishing,it isgenerallypreferableto usemaximumpitch when

towinglinesandaslightlyreducedpitchforful1speed.

RUNNiNG-IN A NEW ENGINE

A newengineshouldnothesubjectedto anyunnecessarystressor loading.Runthe

enginecarefullytobeginwith usingfull speedonly for shortperiods.Increasethe

engineloadinggraduallyduringtheinitial2S hoursrunning.

RememberthaI treatingtheenginesensiblyduring therunning-inperiod will

lengthenthelifeoftheengineappreciably. ~

After thefirst 25hoursrunning:

I.Changeenginesumpoil Page 17

2.Type2HG:Changereversegearbü:xoil Page 18

3.Type2H:Checkclutch Page 39

4.Checkenginealignment Page 49

S.Checkallpipeconnections

. 6.CheckV-belttightness Pages37-38

After thefirst 50-]()(}hoursrunning:

1.Adjustvalveclearances Page 40

2.Forsubsequentroutinemaintenance,followchart

"CAREANDMAINTENANCE" Page 14

10

"~~ - -~~~--