7

1. Crankshaft gear

2. Intermediate gear

3. Camshaft gear

4. Injection pump drive gear

5. Compressor drive gear

6. Intermediate gear for oil pump/coolant pump

7. Drive gear for oil pump/coolant pump

8. Servo pump drive gear

Camshaft

Drive ......................................... Gear

No. of bearings ......................... 7

Bearing journal diameters, min.

Front bearing journal ........... 68.94 mm

2nd ....................................... 66.56 mm

3rd........................................ 64.17 mm

4th ........................................ 63.39 mm

5th ........................................ 60.99 mm

6th ........................................ 60.21 mm

7th ........................................ 56.24 mm

End float, max. ......................... 0.18 mm

Radial clearance (same for all

bearings) max. ...................... 0.079 mm

Max. permitted out-of-round

(new bearings) ..................... 0.05 mm

Bearings, max. permitted wear . 0.05 mm

Lift height min., Camshaft

Inlet...................................... 8.4 mm

Exhaust ................................ 9.0 mm

Valve tappets, max. permitted

radial clearance.................... 0.08 mm

Checking camshaft setting (cold

engine and valve clearance = 0)

At 10°flywheel A.T.D.C. no. 1

cyl. inlet valve should open ...... 4.2–4.8 mm

Max. valve lift:

inlet ...................................... 13.3 mm

exhaust................................. 14.3 mm

Min. valve lift:

inlet ...................................... 13.0 mm

exhaust................................. 14.0 mm

Camshaft bearings

Bearing bores

Front bearing ....................... 69.050–69.075 mm

2nd ....................................... 66.675–66.700 mm

3rd........................................ 64.287–64.312 mm

4th ........................................ 63.500–63.525 mm

5th ........................................ 61.112–61.137 mm

6th ........................................ 60.325–60.350 mm

7th ........................................ 56.350–56.375 mm

Wear max. ........................... 0.050 mm

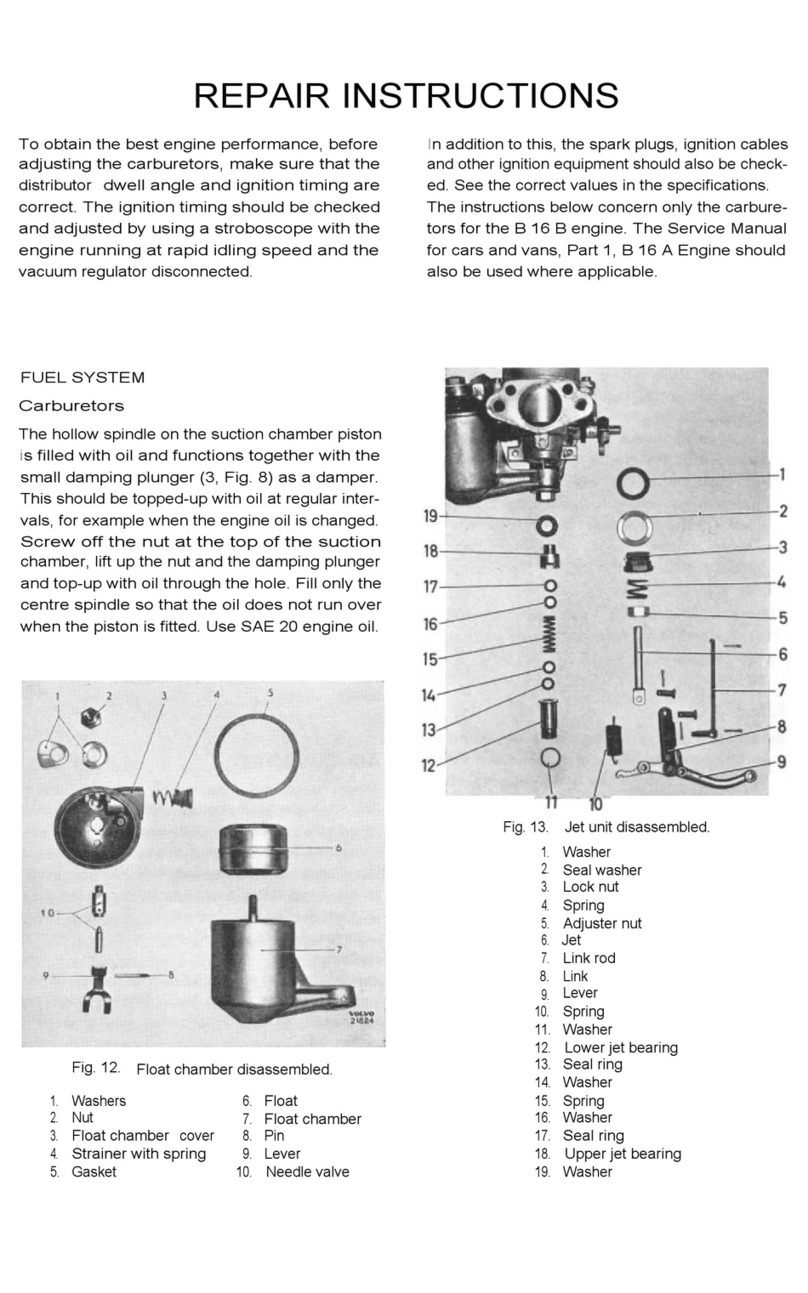

Timing gears

Number of teeth:

crankshaft gear (1)................... 30

intermediate gear (2) ............... 53

injection pump drive gear (4) .. 60

servo pump drive gear (8) ....... 19

camshaft gear (3) ..................... 60

compressor drive gear (5)........ 26

intermediate gear for oil pump

and coolant pump (6)............... 48

drive gear for oil pump and

coolant pump (7) ..................... 21

Backlash, max............................... 0.17 mm

Bearing sleeve, intermediate gear,

diam., max. .............................. 92.106 mm

Bushing, intermediate gear,

diam., max. .............................. 92.158 mm

Radial clearance for intermediate

gear max. ................................. 0.082 mm

Axial clearance for intermediate

gear max. ................................. 0.15 mm