6101

6101

6101

6101 Belt

Belt

Belt

Belt Scale

Scale

Scale

Scale Integrator

Integrator

Integrator

Integrator Operating

Operating

Operating

Operating and

and

and

and Service

Service

Service

Service Manual

Manual

Manual

Manual

2

CATALOGUE

CATALOGUE

CATALOGUE

CATALOGUE OF

OF

OF

OF CHART

CHART

CHART

CHART .................................................................................................................

.................................................................................................................

.................................................................................................................

................................................................................................................. VI

VI

VI

VI

CHAPTER

CHAPTER

CHAPTER

CHAPTER 1

1

1

1 INTRODUCTION

INTRODUCTION

INTRODUCTION

INTRODUCTION .........................................................................................................

.........................................................................................................

.........................................................................................................

......................................................................................................... 1

1

1

1

1.1 G ENERAL ......................................................................................................................................... 1

1.2

T

ECHNICAL SPECIFICATIONS ............................................................................................................ 2

1.3 F EATURES ........................................................................................................................................ 3

1.3.1 Measuring Function .............................................................................................................. 4

1.3.2 Monitoring Function .............................................................................................................. 5

1.3.3 Printing Function ................................................................................................................... 5

1.3.4 Communications (Optional) ................................................................................................. 6

1.4

W

ARRANTY ...................................................................................................................................... 7

1.5 UNPACKING AND INSPECTION ................................................................................................................. 8

1.6 STORAGE ............................................................................................................................................. 8

1.7 SYMBOL .............................................................................................................................................. 8

1.8 H ARDWARE INSTRUCTION ................................................................................................................ 8

1.8.1 Housing .................................................................................................................................... 8

1.8.2 Ambient Condition ............................................................................................................... 8

1.8.3 Power Requirements ................................................................................................................ 8

1.8.4 Speed sensor input ................................................................................................................... 9

1.8.5 Digital I/O Board ( Figure 1-5 ).................................................................................... 10

1.8.6 Load cell input ....................................................................................................................... 13

1.8.7 Analog I/O Board ............................................................................................................... 13

1.8.8 Comm. Board ......................................................................................................................... 13

CHAPTER

CHAPTER

CHAPTER

CHAPTER 2

2

2

2 INTEGRATOR

INTEGRATOR

INTEGRATOR

INTEGRATOR INSTALLATION

INSTALLATION

INSTALLATION

INSTALLATION .............................................................................

.............................................................................

.............................................................................

............................................................................. 14

14

14

14

2.1 G ENERAL ....................................................................................................................................... 14

2.2 6101 I NTEGRATOR

I

NSTALLATION ................................................................................................. 14

2.2.1 Mounting ................................................................................................................................ 14

2.2.2 Safety Precautions .............................................................................................................. 18

2.2.3 Wiring (External Power Supply) ........................................................................................ 19

2.2.4 Input voltage setup ......................................................................................................... 20

2.2.5 Serial Communication ....................................................................................................... 20

2.2.6 Load cell ............................................................................................................................. 22

2.2.7 Integrator analog board ..................................................................................................... 22

2.2.8 Integrator CPU board ........................................................................................................... 24

2.2.9 Digital input/output board ..................................................................................................... 25

2.2.10 Wiring .................................................................................................................................. 26

CHAPTER

CHAPTER

CHAPTER

CHAPTER 3

3

3

3OPERATION

OPERATION

OPERATION

OPERATION ......................................................................................................................

......................................................................................................................

......................................................................................................................

...................................................................................................................... 27

27

27

27

3.1 R UN MENU .................................................................................................................................... 27

3.1.1 General .................................................................................................................................. 27

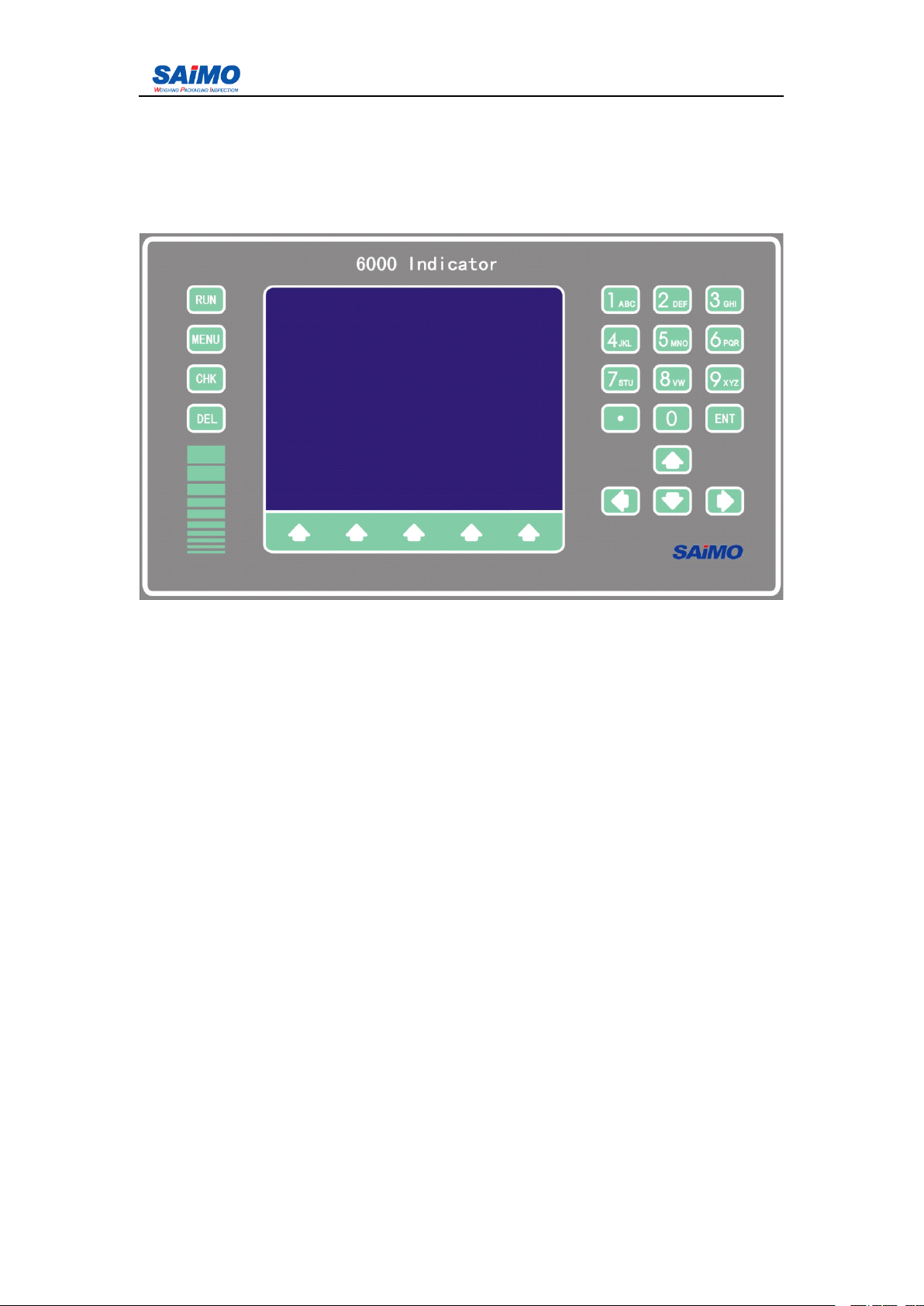

3.1.2 Front panel ............................................................................................................................ 27

3.1.3 Keyboard ............................................................................................................................... 27

3.1.4 Quick setup method ............................................................................................................... 28

3.1.5 Menu display .......................................................................................................................... 29