1161 Ringwood Ct, #110, San Jose, CA 95131, U. S. A. Tel.: (408) 748-9100, Fax: (408) 770-9187 www.analogtechnologies.com

nalog Technologies ALDD28V5A401

Digital High Voltage Constant Current 5A Laser Driver

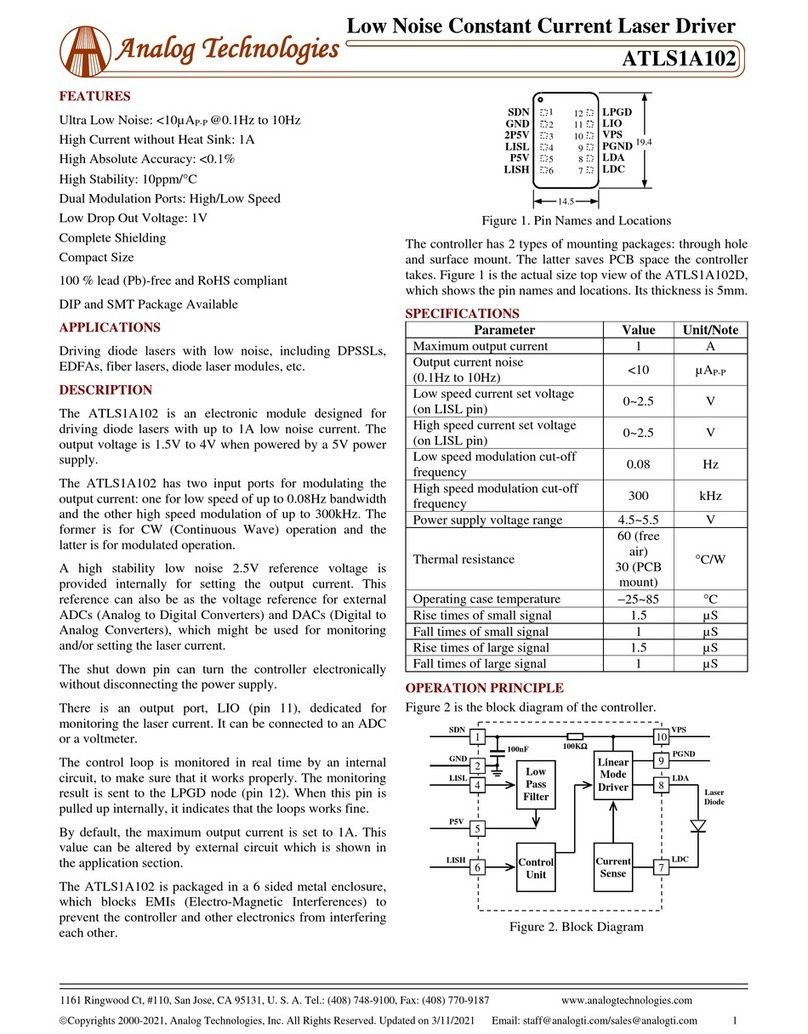

Figure 1. Physical Photo of ALDD28V5A401

FEATURES

Digital display for parameter setting and monitoring

Wide input voltage range: 10V ∼27V

Wide output voltage range: 0.1VVPS to 0.8VVPS (VVPS is

input voltage)

High current capability: 5A

High efficiency: ≥90%

(IOUT=5A @ VLDA=20V&VVPS=27V)

Wide modulation bandwidth: DC ∼10kHz

Compact size: 68.5×61.0×16.6 (mm)

Dual independent current set ports: LISH and LISL

Direct digital modulation control: PCN

Three control states: Operation, Standby and Shutdown

Low output current noise: < 15µAP-P@0.1Hz~10Hz

High current stability: < ±600µA@5A &‒20°C~80°C

Low output ripple voltage: < 15mVP-P@500kHz

Fully shielded

100 % Lead (Pb)-free and RoHS compliant

APPLICATIONS

Drive one or multiple laser diodes for DPSSL, EDFA, and

fiber lasers with low noise and high efficiency.

DESCRIPTION

This laser driver, ALDD28V5A401, is an electronic module

that has all the valuable and important features, but are often

difficult to achieve simultaneously such as: wide input and

output voltage range, high output current capability, high

efficiency, low output noise (but it has an output 6mVp-p

ripple voltage at 500kHz), wide modulation bandwidth, and

small size. The wide output voltage range, 0.1VVPS ~

0.8VVPS, allows driving one or multiple serial laser diodes at

the same time, for up to 5A of well controlled current at high

efficiency. The extremely low noise between DC ~ 10kHz

and low DC current drift make it ideal for driving diode

pumped single mode laser diodes to achieve mode-hop-free

and narrow optical wavelength drift, thus, long coherent

length.

Because of the high efficiency, the laser driver generates a

small amount of heat, thus, no heat sink is necessary for

normal operation. The fully shielded case blocks all the

incoming and outgoing EMIs (Electro-Magnet

Interferences). Therefore, this laser will not interfere other

surrounding electronics, nor will other electronics interfere

with it. The small package saves valuable PCB space in laser

systems. Figure 1 shows the photo of the ALDD28V5A401.

The actual laser current and laser driver temperature are

monitored by dedicated ports. In case the laser driver

temperature exceeds the limit of 80°C, the laser driver will

shut down the output stage by itself and force the laser drive

into Standby Mode. There is a loop good indication output

to tell if the laser driver is working properly.

The laser driver has three states: Operation, Standby and

Shutdown. Under Standby mode, all the laser driver

components works except the output stage, see Figure 4.

Under Shutdown mode, all the components of the laser

driver stops working and the power supply current is

reduced to < 3µA.

This laser driver generates a high accuracy high stability low

noise, 15mVP-P, < 2.5mVRMS, < 8ppm/°C, 4.096V<±2mV,

voltage reference output which can be used for setting the

output current and also be used as the reference voltage for

the ADCs (Analog to Digital Converters)and/or DACs

(Digital to Analog Converters).

The ALDD28V5A401 uses a constant frequency high

efficiency PWM output stage.

Warning: Both the surface mount and the through

hole types of packages can only be soldered manually on

the board by a solder iron of < 310°C (590°F), do not use

a reflow oven to solder this laser driver.

For noise sensitive applications, please be aware that this

laser driver has very low noise between DC to 10kHz, but a

little high ripple output voltage, sine-wave, 15mVP-P, at the

switching frequency, 500kHz.