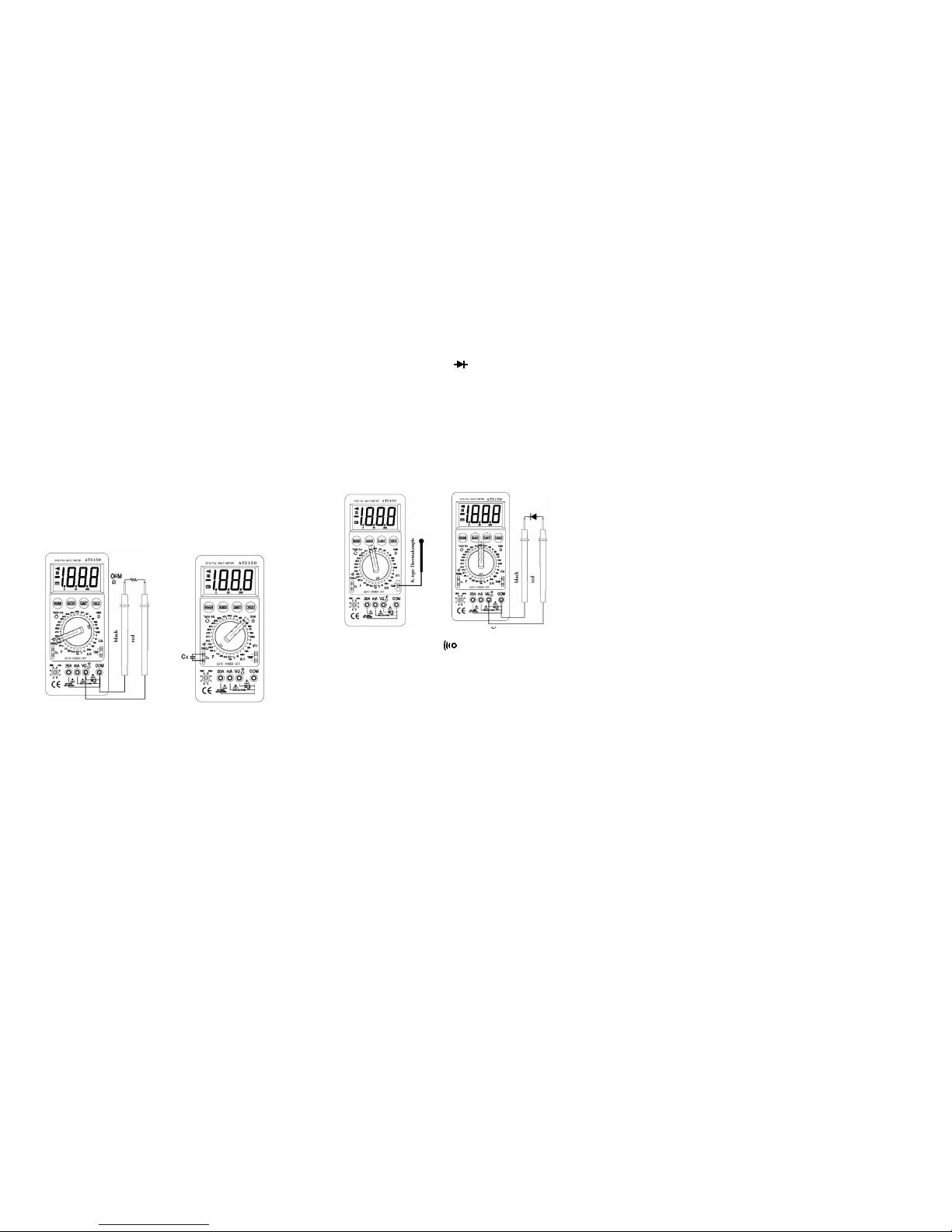

AT2150/B Automotive Tester

User’s Guide

Introduction

AT2150/B series digital multimeter is a 3½ digital with precise

design, convenient for operation, stable performance and with

multi-functions measuring instrument. It was designed with new

style guarantees protective covering, large screen liquid crystal

display. It uniquely incorporate with back light valve features, so it

is suitable to be used in the obscure ray environment operation.

The ”VΩ” is equipped with PTC heat sensitive element at the input

terminal. Therefore, the Function/Range switch has efficient

protection.

AT2150/B series digital multimeter can measure DC Current

and Voltage, Current, AC Current and Voltage, Resistor, Capacitor,

Temperature, Diode and Transistor, Open Circuit and Short Circuit.

In addition, AT2150/B digital multimeter is also suitable for vehicles.

Safety Precautions and Procedures

for your own safety, you must read and follow the procedure in this

instruction manual.

don’t try to use it if the battery cover is not closed properly,

otherwise you may have the danger of electric shock.

make sure the insulation layer has not any damages before use it.

never input signal electronic level exceeding the limited value to

avoid electronic shock or damaging the instrument.

don’t turn the function/range switch when taking measurement.

the potential difference between the measurement public terminal

COM and earth can’t exceed 1000V to avoid electric short.

pay attention if the tested voltage is over DC 60V and AC 42V to

avoid electric shock

if there have a symbol on the LCD display, it indicates low

battery. replace the battery to ensure measurement accuracy.

For the fuse, it must be replaced with an identical model if necessary.

International Symbols

DC Current or Voltage AC Current or Voltage Diode

Buzzer Low Battery Cautions Double Insulation

Danger High Voltage Rotational Speed Closed Angle

Characteristic

Low power consumption CMOS double integration, A/D transform

integrated circuit, auto zero calibration, auto polarity display, low

battery and over range indication.

DC basic accuracy : +0.5% (3 1/2 digits)

Capacitor measurement : 1pF~200uF

Temperature measurement : -40ºC~1000ºC

Full range over-load protection function.

Have back-light valve features, it is suitable to be used in the obscure

ray environment operation.

Auto power off function: the meter will shut off automatically about

15 seconds after no performance.

Maximum display : 1999 (3 1/2 digits)

LCD display : 70 x 48mm big screen, high contrast, Word height :

28mm

Power : one 9V battery (NEDA 1604, 6F22 model or identical)

Low battery indication: mark on display

Size : 192x88x42mm

Weight : approximate 400g (including battery and cover)

Environment conditions :

Operation temperature : 0ºC~40ºC Relative humidity <85%

Storage Temperature : -10ºC~50ºC Relative humidity <85%

Keeping accuracy temperature : 23ºC+5ºC

Relative humidity <75%

Technical Specifications

Accuracy : + (% reading + digit) one year warranty.

Environmental humidity : 23ºC+5ºC

Relative humidity : <75%

Closed Angle Gauge